Pinion Heat Treatment Methods in Gear Slew Drives

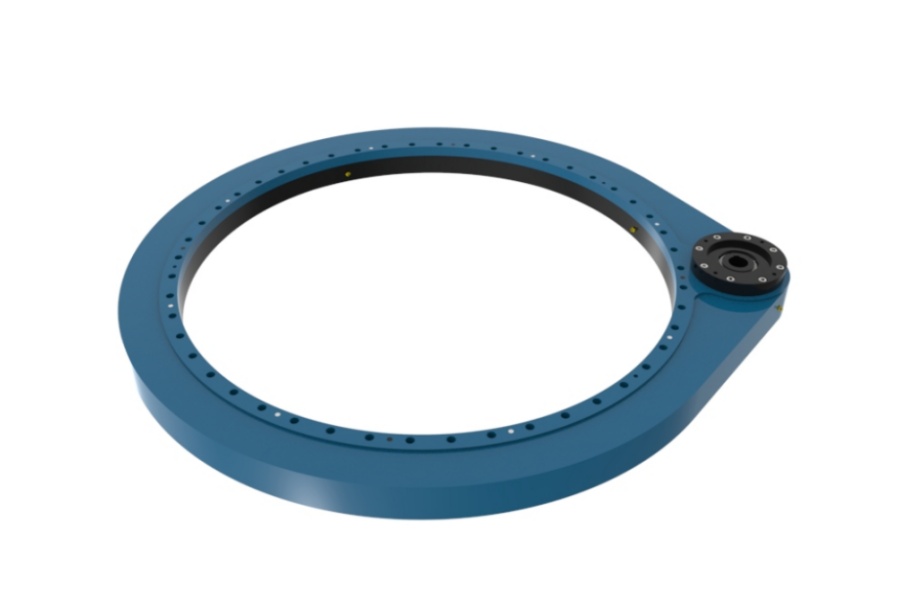

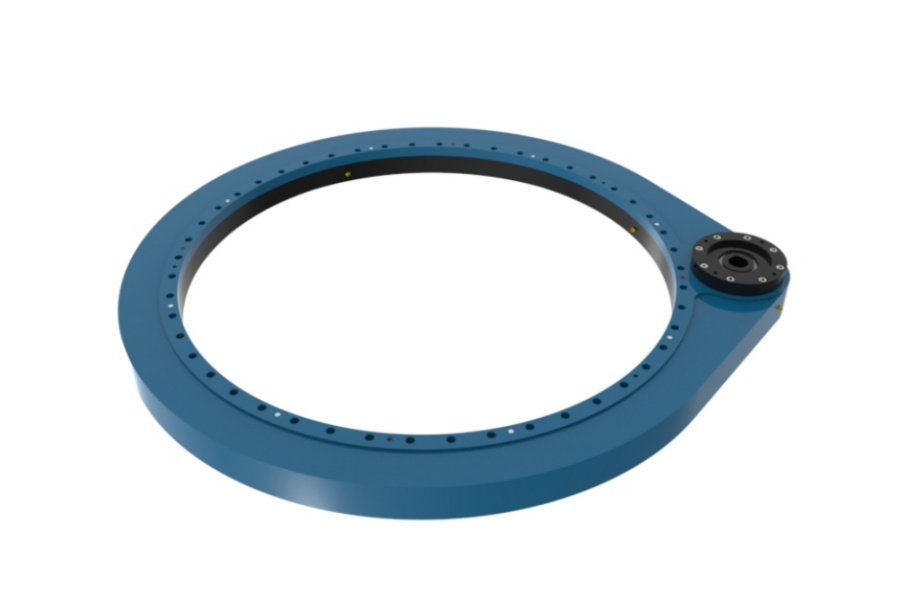

What is Spur Gear Slew Drive

Spur Gear Slew Drive refers to a rotational drive system where a spur-gear pinion directly engages teeth integrated into a slewing ring’s raceway. Characterized by >95% mechanical efficiency and simplified construction, this configuration excels in applications prioritizing energy savings and radial load handling over self-locking capability. Typical implementations include solar trackers, conveyor turntables, and industrial indexing systems operating at 10-150 RPM.

Pinion Heat Treatment Methods for Gear Slew Drives

Material selection and thermal processing fundamentally govern pinion performance. Steel alloys dominate due to their balance of machinability, strength, and thermal process compatibility. Treatment selection depends on:

Operational load spectra (shock/continuous)

Required surface hardness (HRC)

Dimensional stability needs

Production cost targets

Fatigue life expectations

Quenching and Tempering (Q&T)

Process Sequence: Austenitization (850-880°C) → Oil quenching → Tempering (550-650°C)

Microstructure: Tempered martensite/sorbite with 28-35 HRC hardness

Performance Profile:

Balanced core toughness (Charpy impact >40J)

Moderate wear resistance

Minimal distortion vs. surface hardening

Cost Efficiency: Lowest processing expenses

Limitations: Limited surface hardness restricts pitting resistance

Ideal For: Low-speed applications (<30 RPM) with uniform loading or large-diameter gears where distortion control is critical

Induction Hardening

Process Sequence: High-frequency EM field (10-400 kHz) → Rapid austenitization → Precision quenching

Case Properties:

Depth: 1-5mm adjustable via frequency/power

Hardness: 52-58 HRC martensitic case

Technical Advantages:

Localized treatment minimizes distortion

Cycle times under 60 seconds

Compressive surface stresses (-400 to -800 MPa)

Process Control Requirements:

Scanning coil speed ±2mm/s tolerance

Temperature monitoring (pyrometers ±15°C)

Failure Risks: Grinding burns if post-heat treatment machining is needed

Optimal Use: Medium-duty drives handling shock loads (e.g., material handling)

Carburizing (Case Hardening)

Thermochemical Process: 930-950°C carburizing (Cp=0.8-1.2%) → Diffusion → Quench → -70°C cryo → 160-200°C temper

Case Characteristics:

Depth: 0.8-1.5mm (validated at 550 HV)

Surface: 58-63 HRC hardness

Core: 35-45 HRC toughness

Metallurgical Benefits:

Residual compressive stresses >-1000 MPa

Retained austenite <15%

Superior bending fatigue strength

Quality Validation:

Microhardness gradient testing

Microstructure rating per ISO 6336-5

Cost Considerations: 40-60% higher than induction hardening

Premium Applications: High-precision solar trackers and medical equipment requiring >100 million cycle life

Nitriding

Low-Temperature Process: 500-520°C diffusion in NH₃ atmosphere (20-80 hours)

Surface Layer Properties:

Compound zone: 5-20μm Vickers >1,000 HV

Diffusion zone: 0.2-0.8mm depth

Technical Merits:

Distortion <0.05mm/m

No quenching required

Enhanced corrosion resistance

Performance Constraints:

Shallow case depth limits Hertzian stress to <1,200 MPa

Avoid impact loading due to brittle compound layer

Process Variants: Gas (precise control) vs. Plasma (faster)

Best Suited For: Large-diameter pinions in chemical processing equipment where dimensional stability is paramount

Critical Selection Guidelines

Method | Surface HRC | Case Depth | Distortion | Cost Index |

Quenching/Tempering | 28-35 | Full Section | Low | 1.0x |

Induction Hardening | 52-58 | 1-5mm | Medium | 1.8x |

Carburizing | 58-63 | 0.8-1.5mm | High | 3.5x |

Nitriding | 65-72 (HV) | 0.2-0.8mm | Ultra-Low | 2.7x |

Spur Gear Slew Drive Characteristics

Radial load dominance supports 2.5x higher overturning moments than worm drives. Operational speeds reach 150 RPM without thermal derating. Backlash control demands AGMA Class 8+ manufacturing. Compact design reduces installation footprint by 20% vs. planetary systems. External braking is mandatory for position holding.

Industrial Applications of Spur Gear Slew Drive

Solar tracker azimuth drives leverage carburized pinions for 20-year lifespans. Packaging conveyor turntables use induction-hardened gears for shock resistance. Medical scanning gantries require nitrided pinions for micron-level precision. Light crane rotation systems implement Q&T for cost-effective performance.

Price Determinants of Spur Gear Slew Drive

Pinion heat treatment contributes 15-30% of total drive cost. Carburizing adds $120-250 per pinion versus $40-80 for induction hardening. Material choice (8620 vs. 20MnCr5) creates 20% cost variance. AGMA quality class upgrades (8→10) increase grinding costs 35%. Cryogenic treatment adds $15-30 per unit. Corrosion-resistant coatings (Zn-Ni) add 8-12%.

Supplier of Spur Gear Slew Drive

LYRADRIVE supplies Spur Gear Slew Drives with application-optimized pinion treatments: Their PRO series features 1.2mm case-carburized 20MnCr5 pinions achieving 200 million cycles in solar tracking. VALUE line utilizes induction-hardened 4140 steel for material handling, while MEDICAL grade offers plasma-nitrided 31CrMoV9 for zero-distortion precision.