Torus Worm Classifications in Slew Drives

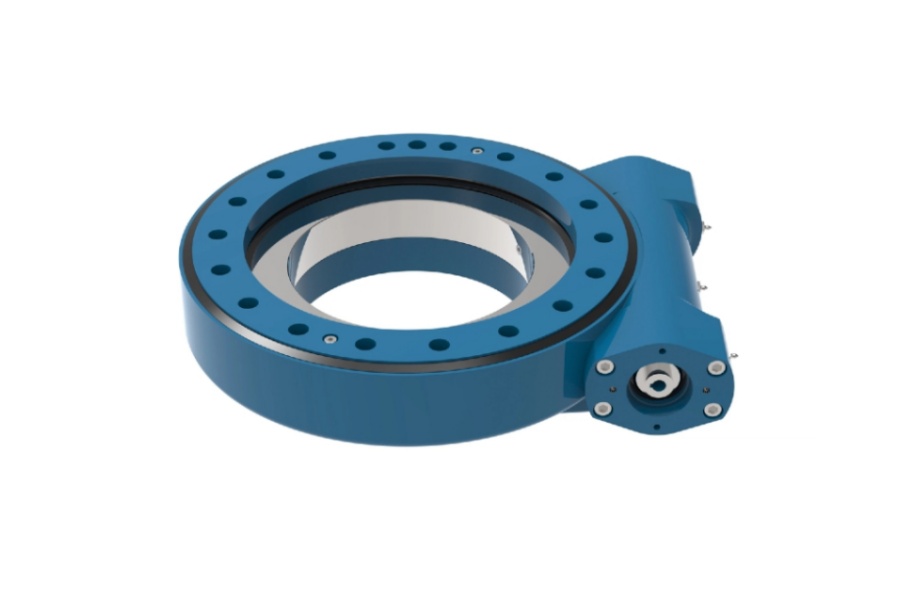

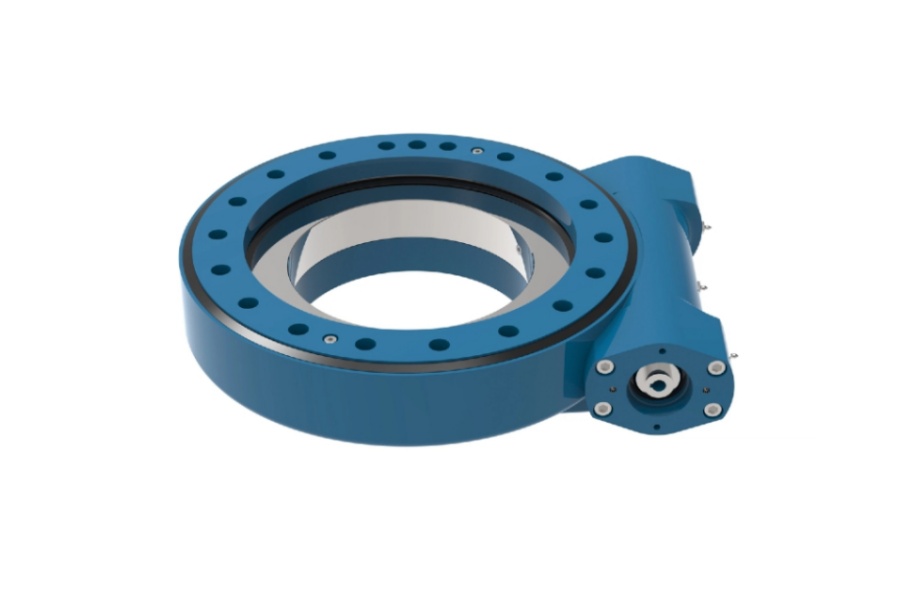

What is Slew Drive Enclosed

Slew Drive Enclosed denotes a heavy-duty rotary drive system integrating a sealed housing that fully protects the torus worm gear mechanism and slewing bearing from environmental contamination. Characterized by exceptional sealing integrity (IP66-IP69K), this design prioritizes reliability in abrasive, corrosive, or wet environments where conventional drives fail. Unlike open configurations, it maintains consistent lubrication integrity while handling high combined loads through precision-ground worm gearsets. Typical applications include offshore cranes, mining equipment, and wind turbine pitch systems demanding zero-maintenance operation.

Torus Worm Classifications in Slew Drives

The torus worm's hourglass profile – formed by revolving a concave circular arc around its axis – enables superior load distribution in enclosed slew drives. Classification depends on the generating geometry used to create the worm thread flank:

Straight Sided Torus Worms (TSL Type)

Geometry Basis: Generated using a straight-line cutting tool.

Performance Profile: Achieves multi-tooth engagement with dual contact lines under load. This expansive contact area reduces Hertzian contact stresses by 30-40% compared to cylindrical worms while enhancing lubricant film formation. Ideal for moderate-to-high shock load applications like excavator rotators.

Technical Constraints: Requires micron-level alignment precision during manufacturing. Post-hardening grinding complexity limits surface hardness to ≤58 HRC in production environments.

Single Enveloping Torus Worms (TVP Type)

Geometry Basis: Worm flanks generated by conjugate action with a theoretical plane.

Subtypes & Manufacturing:

Straight-Cut TVP: Generating plane perpendicular to wheel axis. Enables standard hobbing for worm wheels, slashing production costs 25%.

Helical-Cut TVP: Angled generating plane improves load sharing for high-torque applications (>20kNm).

Performance Advantages: Maintains multi-tooth contact with single contact lines. Delivers 92-94% efficiency in continuous duty cycles – 15% higher than cylindrical equivalents. Grinding-friendly geometry achieves 60-62 HRC surface hardness.

Operational Limit: Avoid axial loads exceeding 10% of radial capacity to prevent premature flank wear.

Double Enveloping Torus Worms (TOP Type)

Geometry Basis: Both worm and wheel surfaces conjugated against a virtual plane.

Performance Superiority: Synchronous multi-tooth contact with dual load-bearing lines maximizes contact area by 70-80% versus TSL types. Enables industry-leading torque density (450-550 Nm/kg) and peak efficiencies (95-97%) under optimal lubrication.

Manufacturing Complexity: Requires 5-axis CNC grinding with <5μm profile tolerance. Dedicated wheel-cutting tools increase production costs 40% over TVP systems.

Failure Prevention: Mandatory oil filtration (β₅≥200) to avoid abrasive wear on precision surfaces.

Critical Performance Comparison

Double enveloping (TOP) worms provide unparalleled torque density and efficiency but demand premium manufacturing investment. Single enveloping (TVP) types balance performance with practical manufacturability, particularly in helical configurations. Straight-sided (TSL) worms offer robust simplicity for shock-load scenarios but sacrifice efficiency. All torus types significantly outperform cylindrical worms in load distribution and longevity when properly engineered.

Key Characteristics of Slew Drive Enclosed

Contamination Immunity: Multi-labyrinth seals with FKM lip seals block particulate ingress down to 1μm particles.

Torque Density: TOP-type gearing transmits ≥3.2x more torque than equivalently sized spur gear drives.

Zero-Backlash Precision: Preloaded taper roller bearings maintain ≤1 arc-minute positional repeatability.

Thermal Management: Ribbed aluminum housings dissipate 450W heat load without external cooling.

Corrosion Defense: Electroless nickel plating (ENP) withstands 1,000hr salt spray per ASTM B117.

Maintenance Elimination: Lifetime lubricated (Molykote PG-75) with 100,000-hour service intervals.

Industrial Applications of Slew Drive Enclosed

Offshore Wind: Pitch/yaw systems surviving Category 5 seawater immersion (ISO 19901-6)

Deep Mining: Shaft conveyor swing drives operating in >95% humidity with silica dust

Port Machinery: Container crane rotators enduring 8g shock loads during vessel roll

Steel Production: Ladle turret drives in 80°C ambient with iron oxide contamination

Military Vehicles: Turret drives meeting MIL-STD-810H vibration specifications

Price Determinants of Slew Drive Enclosed

Worm Gearset Complexity: TOP-type adds 35-50% cost premium over TVP; helical TVP 15% > straight TVP

Sealing Hierarchy: IP69K certification requires triple-seal labyrinths (+22% cost vs IP66)

Material Science: Vacuum-arc-remelted steel (VAR 34CrNiMo6) increases fatigue life 300% at +40% cost

Precision Certification: DIN Class 12 gearing compliance adds 18% machining/time cost

Load Capacity Scaling: Moment load rating increase from 200kNm → 500kNm doubles base price

Thermal Mitigation: Integrated aluminum heat sinks add 8-12% versus standard housings

Compliance Testing: DNV-GL/CE/ATEX certification adds 15-25% administrative overhead

Engineering Partner for Slew Drive Enclosed Solutions

LYRADRIVE delivers IP69K-rated Slew Drive Enclosed units featuring TOP-type torus worms precision-ground to AGMA 13 accuracy. Their TVP-Helical series achieves 96% efficiency in steel mill applications, while TSL variants support 12g shock loads in defense platforms. Custom engineering includes ENP coatings for offshore deployments and integrated thermistors for thermal protection.