Spur Gear Slew Drive Shaft Connection Methods

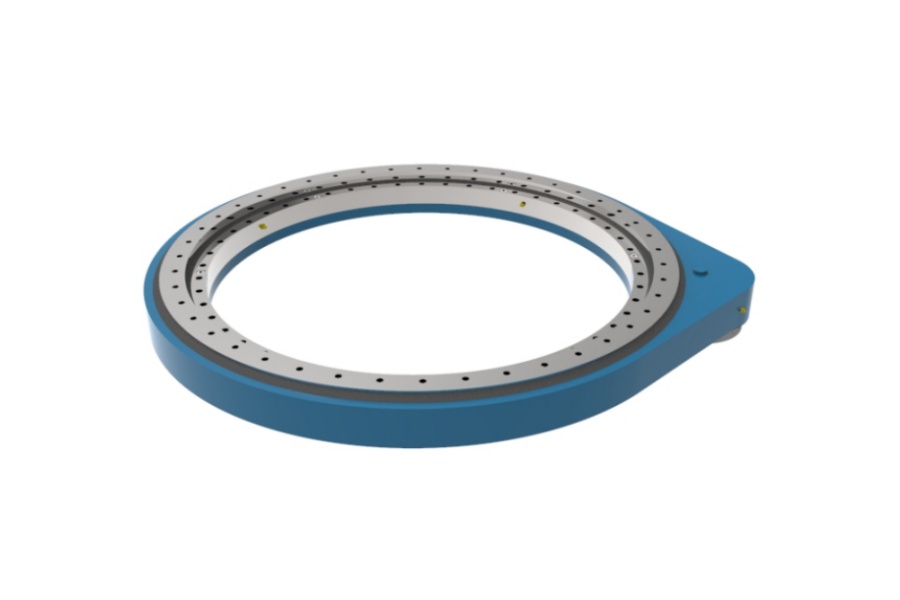

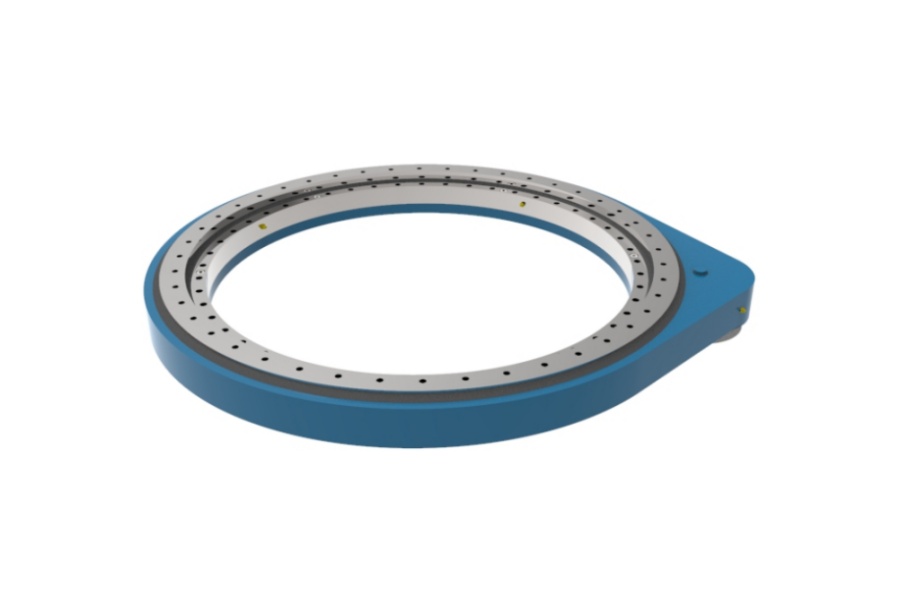

What is Spur Gear Slew Drive

Spur Gear Slew Drive refers to a rotary motion system where a spur gear (pinion) directly meshes with the internal or external teeth of a slewing ring bearing. This configuration delivers high efficiency (>95%), simplified construction, and superior radial load capacity compared to worm gear alternatives. Characterized by lower manufacturing costs and suitability for moderate-to-high-speed operations, it lacks inherent self-locking and requires external braking. Common applications include solar trackers, conveyor turntables, and automated indexing systems where energy efficiency and straightforward maintenance are prioritized.

Spur Gear Slew Drive Shaft Connection Methods

The integrity of the connection between the motor shaft and the drive’s input pinion shaft directly impacts performance, safety, and service life. Selection depends on torque requirements, rotational speed, alignment precision, installation constraints, and maintenance needs.

Parallel Key Connections

Mechanics: Rectangular key seated in matched keyways on shaft and hub.

Advantages: Manufacturing simplicity, easy installation/disassembly, cost-effectiveness, reliable torque transfer under moderate loads.

Suitability: Ideal for high-speed applications (≤6,000 RPM) demanding precise concentricity. Handles shock/variable loads effectively.

Critical Considerations:

Requires exact keyway tolerances (ISO 7734) to prevent fretting.

Stress concentration at keyway corners necessitates fillet radii.

Secure end-play control via set screws or clamping collars.

Failure Modes: Key shear under overload, keyway deformation, fretting corrosion.

Taper Key Connections

Mechanics: Wedge-shaped key driven into tapered keyway, generating radial force.

Advantages: Transmits torque + unidirectional axial load; no auxiliary fasteners needed.

Limitations:

Induces eccentricity (≥0.1mm TIR), unsuitable for precision alignment.

High vibration/shock loads cause loosening.

Avoid for speeds >1,500 RPM.

Installation: Requires precise taper angle matching (typically 1:100).

Tangential Key Connections

Mechanics: Paired wedge keys driven perpendicular to the shaft axis.

Advantages: High torque capacity (up to 3x parallel keys); robust for heavy machinery.

Drawbacks:

Severe shaft weakening (≥25% cross-section loss).

Poor concentricity (≥0.3mm TIR).

Bidirectional torque requires dual 120°-offset keys.

Application: Low-speed, high-torque scenarios (e.g., mining equipment).

Splined Connections

Mechanics: Axial teeth engagement across shaft/hub interface.

Types: Involute (ISO 4156), straight-sided, serrated.

Advantages:

Highest torque density and torsional stiffness.

Precise centering (diametral/angular misalignment ≤0.05mm).

Facilitates axial movement (sliding splines).

Disadvantages: Complex machining, higher cost, requires precise lubrication.

Design: Profile modifications prevent edge-loading in misalignment.

Woodruff Key Connections

Mechanics: Semi-circular key seated in curved shaft keyway.

Advantages: Self-aligning capability; easy hub assembly/disassembly.

Limitations:

Reduced shaft strength (deep keyway).

Limited torque capacity; prone to roll-out under reversing loads.

Use Case: Light loads, conical shaft ends, or secondary retention.

Pin Connections

Mechanics: Dowel pins pressed into reamed holes through hub/shaft.

Advantages: Zero backlash, uniform load distribution with multi-pin setups.

Critical Process:

Requires interference fit (H7/p6).

Hole parallelism ≤0.01mm/mm.

Combined with parallel keys for high-vibration environments.

Failure Risk: Shear fracture under cyclic overload.

Interference Fit Connections

Mechanics: Hub bore diameter < shaft OD, creating friction-locked joint.

Advantages:

Perfect concentricity; maximizes shaft strength.

Transmits torque/axial/radial loads without stress concentrators.

Methods: Thermal expansion (hub heating), hydraulic pressure, or force press.

Design Rules:

Calculate minimum interference using Lamé equations.

Surface finish ≤Ra 1.6μm.

Combine with keyed joints for shock loads (e.g., crushers).

Taper Key Medium Low Poor Low

Spur Gear Slew Drive Key Characteristics

High Efficiency: Minimal sliding friction achieves >95% energy transfer.

Radial Load Dominance: Optimized for applications with high overturning moments.

Speed Capability: Sustains higher rotational speeds than worm gear equivalents.

Backlash Sensitivity: Requires precise gear machining (AGMA Class 8+) for positional accuracy.

Compact Design: Simplified architecture reduces footprint vs. planetary/worm drives.

Maintenance Accessibility: Easy gear inspection/lubrication without disassembly.

Typical Applications for Spur Gear Slew Drives

Solar Energy: Single-axis trackers (SAT) requiring efficiency for panel positioning.

Material Handling: Conveyor sorting turntables, pallet positioners (≤20kN radial load).

Packaging Automation: Rotary fillers, capping machines, labeling systems.

Medical Equipment: Radiation therapy gantries, surgical arm rotators.

Aerospace: Satellite antenna rotators, test rig positioning.

Light Infrastructure: Billboard rotators, stage machinery turntables.

Factors Influencing Spur Gear Slew Drive Price

Slewing Bearing: Size (diameter), dynamic load rating (kNm), gear type (internal/external), sealing (IP rating).

Gear Quality: Module size, case hardening depth (CHD ≥1.2mm), grinding precision (AGMA Class), material (20MnCr5 vs. 8620).

Housing Complexity: Sand-cast vs. machined billet; integrated cooling fins/mounts.

Shaft Connection: Splined input (DIN 5480) adds 15–25% cost vs. keyed shafts.

Ancillary Components: Brake torque rating (Nm), encoder resolution (bits), motor efficiency (IE4 premium).

Environmental Protection: IP69K sealing, marine-grade coatings (ASTM B117 salt spray ≥1,000hrs).

Certifications: ISO 9001, CE, DNV-GL marine compliance.

Order Volume: Unit cost decreases 18–30% for batches >50 units.

Supplier of High-Performance Spur Gear Slew Drives

LYRADRIVE manufactures precision Spur Gear Slew Drives with industry-leading efficiency (tested to ISO 1328-1 standards) and customizable shaft interfaces. Their solutions integrate optimized splined, keyed, or tapered connections validated through FEA torque-cycle simulations, serving global solar, automation, and material handling sectors with a 24-month performance warranty.