Accelerating Custom Slew Drive Solution Development

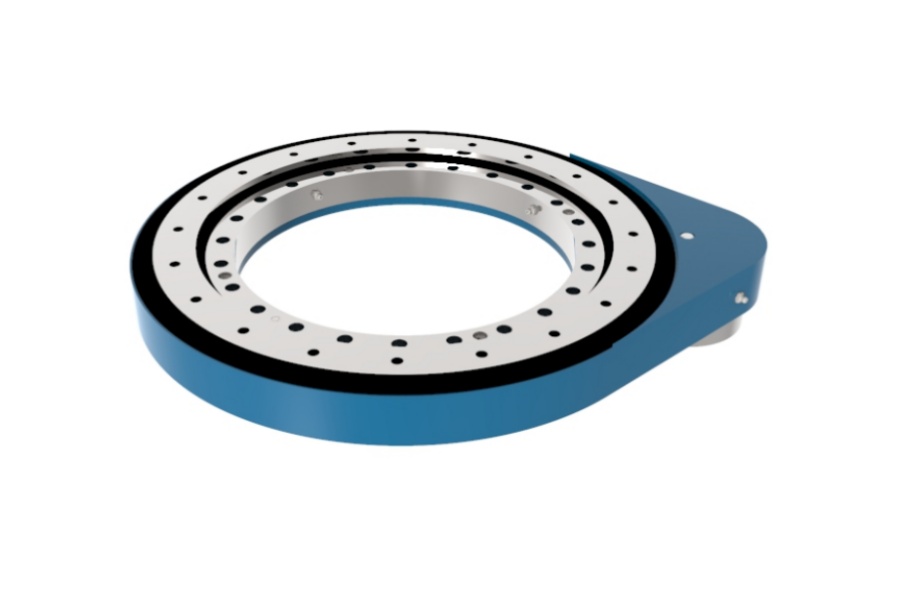

What is Slew Drive

Slew Drive represents an integrated rotational power transmission system combining a gear reducer with a slewing bearing in a single compact housing. This critical component converts high-speed motor input into controlled, high-torque rotational output while simultaneously supporting substantial axial, radial, and moment loads. Essential across heavy machinery and precision positioning systems, its unique dual-function design eliminates complex drivetrain assemblies while delivering robust motion control.

LYRADRIVE's Rapid Solution Methodology

LYRADRIVE leverages decades of engineering expertise to accelerate custom slew drive development through a proven three-phase approach:

Phase 1: Intelligent Analogy Application

Standards-Based Benchmarking: Cross-reference 50+ existing drive configurations against client requirements

Modular Component Adaptation: Modify proven gear sets, bearing arrangements, and sealing systems

Load Profile Mapping: Match torque/load characteristics to validated historical designs

80% solution development within 48 hours

Phase 2: Application-Driven Parameterization

Operational Environment Analysis: Evaluate temperature extremes, contamination risks, and duty cycles

Structural Integration Study: Optimize mounting interfaces and spatial constraints

Motion Profile Configuration: Define rotational speed, positioning accuracy, and backlash requirements

Failure Mode Prevention: Incorporate industry-specific durability enhancements

Phase 3: Precision Engineering Calculation

Gear Module Optimization: Calculate bending strength requirements (σ_F) and apply 10-20% safety margin

Contact Stress Validation: Verify surface durability (σ_H) through center distance/pinion diameter analysis

Performance Simulation: Run FEA validation on preliminary dimensions

Iterative Refinement: Adjust parameters based on simulation outcomes before prototyping

Validation & Client Alignment

Perform comprehensive stress analysis on critical interfaces

Conduct thermal and fatigue life simulations

Present 3D models and performance data for client review

Finalize specifications through collaborative engineering review

Key Features of Modern Slew Drives

Space-Optimized Integration: Combines rotation and support functions in minimal footprint

Exceptional Load Capacity: Handles combined radial/axial/moment loads exceeding 500,000 Nm

Precision Motion Control: Achieves positioning accuracy within ±0.1°

Environmental Resilience: IP66-IP69K protection ratings with wide temperature tolerance (-40°C to +120°C)

Maintenance Efficiency: Lifetime lubrication systems with 20,000+ hour service intervals

Industrial Applications

Renewable Energy: Solar tracker positioning (single/dual axis), wind turbine yaw/pitch systems

Heavy Machinery: Crane jib rotation, excavator attachments, drilling rig turntables

Material Handling: Automated warehouse rotators, palletizing systems, conveyor diverters

Defense Systems: Turret drives, radar positioning, missile launcher articulation

Medical Technology: Radiation therapy gantries, surgical robot joints

Transportation: Railway turntables, vehicle lifting platforms

Pricing Determinants

Load Capacity Tier: Costs increase exponentially beyond 100kN basic dynamic load

Precision Class: ISO 492 P2 precision bearings add 25-40% over standard P0

Gear Technology: Hardened spiral bevel gears cost 30% more than spur gear variants

Environmental Protection: IP68+ sealing adds 15-25% to base price

Material Selection: Stainless steel construction doubles cost vs carbon steel

Certification Requirements: DNV-GL/CE/UL certifications add 10-20%

Production Volume: Unit cost decreases 18-22% per 100-unit quantity increase

Slew Drive Technology Partner: LYRADRIVE

LYRADRIVE delivers engineered rotation solutions through our three-pillar approach: Standard Platform Utilization (50+ base models), Application-Optimized Customization, and Rapid Prototyping Capability. Our technical team accelerates development by combining proven modular designs with advanced simulation tools, typically delivering validated concepts within 72 hours. Specializing in extreme-environment solutions for solar, wind, and heavy industries, we maintain cross-industry expertise that transforms complex requirements into reliable mechanical systems.