The Ultimate Power Transfer Solution: Unveiling the Medium Duty Gear Slewing Drive SP-M 0741

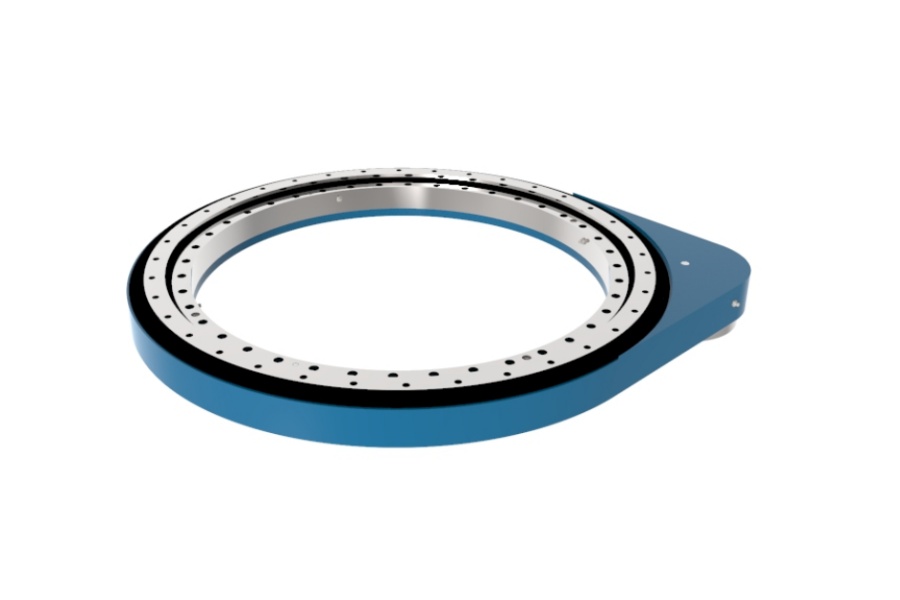

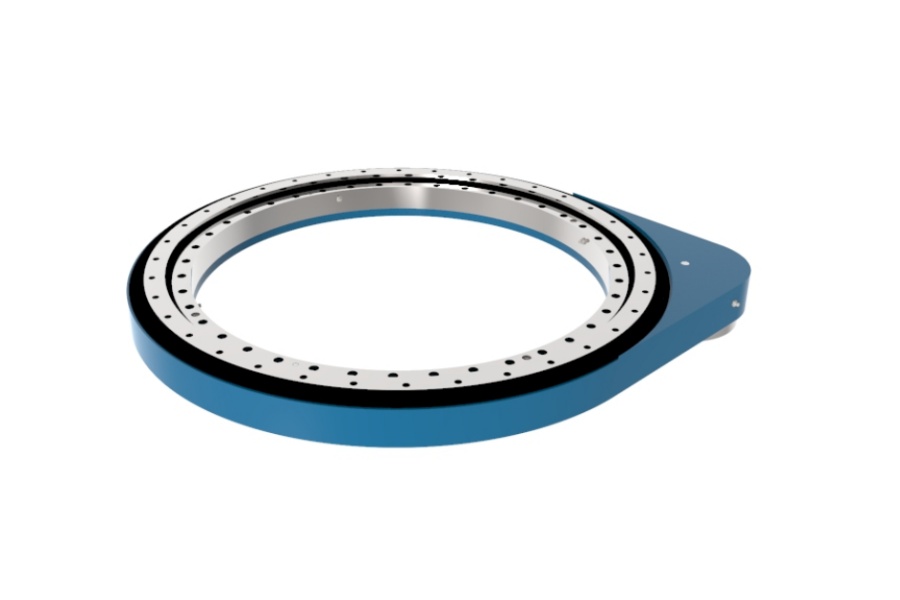

What Exactly is the Medium Duty Gear Slewing Drive SP-M 0741?

The SP-M 0741 represents a specific model within a category of essential mechanical power transmission components known as slewing drives or slewing bearings. Unlike simple bearings, these integrated units combine a large-diameter rolling-element bearing (typically crossed roller or ball bearing) with an internal gear mechanism (often worm gear or planetary) and a compact housing. The SP-M 0741 designation signifies its place in a Medium Duty product line, engineered to handle substantial but not extreme rotational loads and moments. Its core function is to efficiently transfer high torque from a compact drive motor (electric or hydraulic) into controlled, 360-degree rotational motion of a platform, arm, structure, or turret mounted directly onto it. This integrated design eliminates complex external gearing, saving space, reducing weight, and simplifying assembly and maintenance.

The Critical Need for Slewing Drive Replacement

Machinery doesn't last forever, and slewing drives are critical wear components. Failure can lead to catastrophic downtime, safety hazards, and costly repairs. Recognizing the signs for SP-M 0741 replacement is crucial. These include excessive backlash (looseness in rotation), unusual grinding or binding noises during operation, increased effort required for rotation, visible wear on gear teeth or bearing races, leakage of lubricants, or failure to hold position under load. Timely replacement with a genuine or compatible unit like the SP-M 0741 is essential to restore machine integrity, safety, and operational efficiency. Proactive maintenance and monitoring can significantly extend service life, but having a reliable replacement source is paramount for minimizing operational disruption.

The Heart of Crane Movement: Crane Rotation Drive

One of the most demanding and vital applications for a drive like the SP-M 0741 is in crane rotation drives. Whether it's a mobile crane, a knuckle boom crane, or a tower crane slewing ring, the ability to smoothly and precisely rotate the boom or superstructure under full load is non-negotiable. The slewing drive serves as the literal pivot point, transmitting immense torque from the crane's hydraulic or electric motor to rotate the entire upper works. It must handle not just the weight of the load but also dynamic forces from swinging, wind, and inertia. The SP-M 0741, designed for medium duty applications, excels in smaller cranes, material handlers, compact lifters, and auxiliary lifting equipment where reliable, controlled rotation is essential for safe and efficient operation. Its robust construction ensures stability and precise positioning critical for lifting operations.

Ensuring Continuity: Slewing Drive Compatible with SP-M 0741

When replacing a worn SP-M 0741 or designing a new system around its specifications, compatibility is key. A slewing drive compatible with the SP-M 0741 must match several critical parameters to ensure a seamless fit and equivalent performance. This includes identical mounting bolt patterns (PCD - Pitch Circle Diameter), matching bolt sizes and quantities, the same overall height and housing dimensions, identical shaft interface specifications (spline type/size or keyway), equivalent internal gear ratios, and matching torque, axial load, radial load, and moment capacity ratings. Utilizing a truly compatible unit guarantees structural integrity, maintains the machine's center of gravity, ensures proper meshing with the drive pinion, and delivers the expected performance and lifespan. Always verify compatibility specifications meticulously before procurement.

Unbeatable Performance: Key Features of the Medium Duty Gear Slewing Drive SP-M 0741

The SP-M 0741 distinguishes itself through a suite of features engineered for durability and performance in medium-duty industrial environments. Its foundation is a high-strength alloy steel housing, precision machined for dimensional accuracy and rigidity. Internally, hardened and ground gear teeth (worm wheel and worm shaft, or planetary gears) ensure efficient power transmission and exceptional wear resistance, minimizing backlash over time. Robust, pre-lubricated crossed roller or ball bearings provide high load capacity and smooth rotation. Sealing systems are critical; the SP-M 0741 typically employs advanced multi-lip seals and often features grease purge fittings to protect against contaminants like dust, dirt, and moisture, extending service intervals and internal component life. Efficient heat dissipation design prevents overheating under continuous operation. Many models offer options for integrated parking brakes or position sensors. This combination delivers high torque density, precise positioning, low maintenance requirements, and outstanding reliability under demanding conditions.

Powering Diverse Industries: Applications of the SP-M 0741

The versatility of the Medium Duty Gear Slewing Drive SP-M 0741 makes it indispensable across numerous sectors. In solar energy, it precisely tracks the sun's movement in photovoltaic panel arrays and concentrated solar power heliostats. Material handling relies heavily on it for the smooth rotation of conveyor turntables, automated guided vehicles (AGVs), and robotic arms. The construction and agriculture industries utilize it in crane jibs, compact excavator attachments, irrigation systems, and grain augers. Forestry equipment like harvesters and forwarders depend on its robust rotation for booms and grapples. It's crucial in wind turbine yaw systems (smaller turbines or pitch control), antenna positioning systems for communication and radar, medical imaging equipment, stage and lighting rigs, and even specialized vehicles like fire truck turrets. Essentially, anywhere controlled, powerful rotation is needed in a compact footprint within the medium-duty range, the SP-M 0741 is a prime candidate.

Understanding Investment: Factors Influencing Medium Duty Gear Slewing Drive SP-M 0741 Price

The price of an SP-M 0741 slewing drive is not arbitrary; it reflects the complexity of its engineering and manufacturing. Key cost drivers include the specific internal gear configuration – worm gear drives often differ in cost from planetary designs. The grade, heat treatment, and precision grinding of the internal gears and bearing components significantly impact both performance and price. Higher load capacities (axial, radial, moment) and torque ratings necessitate more robust materials and construction, increasing cost. The type and quality of sealing systems are crucial for longevity, especially in harsh environments, and better seals add cost. Integrated features like parking brakes, absolute encoders, or specialized position sensors represent optional extras that increase the unit price. The material specifications for the housing and internal components (e.g., specific alloy grades) influence cost. Precision manufacturing tolerances required for smooth operation and low backlash demand advanced machining, adding to the expense. Finally, economies of scale apply; larger order volumes typically command lower unit prices. Understanding these factors helps in evaluating value versus cost.

Supplier of SP-M 0741

When performance, durability, and technical support matter, sourcing your Medium Duty Gear Slewing Drive SP-M 0741 from a reputable manufacturer is critical. LYRADRIVE has established itself as a leading provider in this specialized field. They bring deep engineering expertise to the design and production of slewing drives, ensuring components like the SP-M 0741 meet rigorous quality standards. LYRADRIVE typically employs stringent quality control processes throughout manufacturing, often including material certification, dimensional checks, and performance testing. Beyond supplying the core unit, they provide invaluable technical support for selection, integration, and troubleshooting. Understanding the critical nature of these components, LYRADRIVE often offers customization options to tailor the SP-M 0741 to specific application requirements, such as unique mounting flanges, shaft configurations, or sealing solutions for extreme environments. Choosing LYRADRIVE means partnering with a supplier committed to delivering not just a product, but a reliable rotational solution backed by expertise and a focus on customer success. Their commitment to quality ensures the SP-M 0741 performs reliably, maximizing uptime and minimizing total cost of ownership for your equipment.

Investing in the right rotational drive technology is fundamental to the efficiency and longevity of your machinery. The Medium Duty Gear Slewing Drive SP-M 0741, particularly when sourced from a trusted partner like LYRADRIVE, provides the robust, reliable, and precise power transfer solution essential for success across a vast array of demanding industrial applications. Its engineered features deliver the performance needed to keep critical operations moving smoothly and efficiently.