Unlock Precision Motion: The Medium Duty Powerhouse Driving Industrial Efficiency

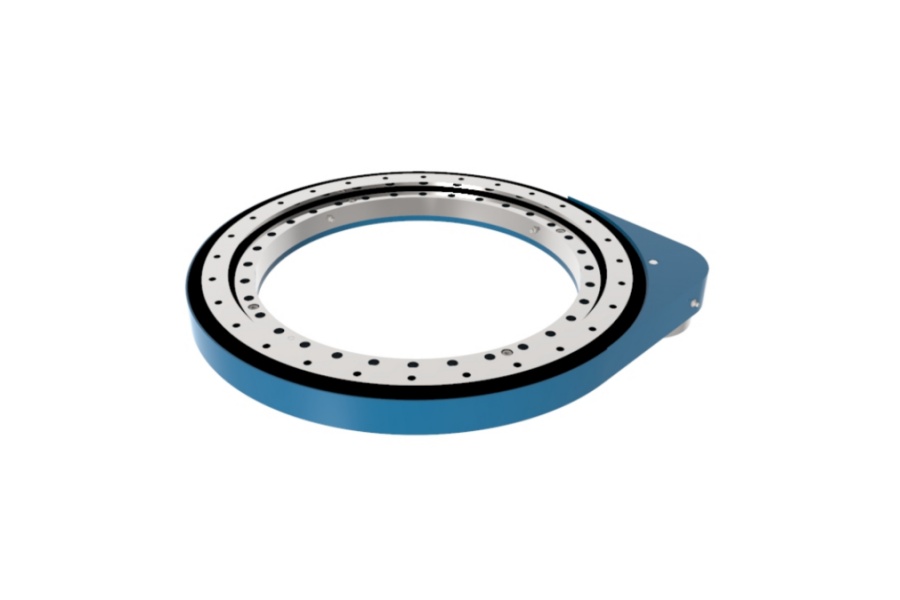

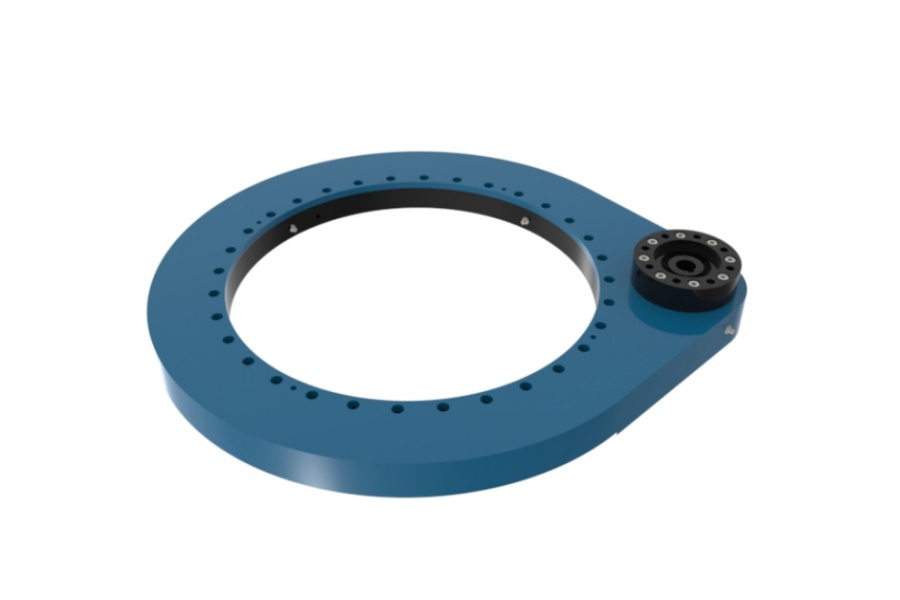

What is the Medium Duty Gear Slewing Drive SP-M 0541?

At its core, the SP-M 0541 is a mechanical gearbox specifically designed to facilitate slow-speed, high-torque rotation around a single vertical axis – known as slewing. It integrates critical components into a compact, sealed housing: a high-precision worm gear set (often featuring hardened steel), robust bearings (typically tapered roller bearings for handling combined loads), durable housing (cast iron or high-strength steel), and advanced sealing systems. The "Medium Duty" classification indicates its optimized capacity range. It bridges the gap between lighter-duty units used in smaller applications and the massive, ultra-heavy-duty drives found in giant cranes or heavy mining equipment. The SP-M 0541 is engineered to handle substantial radial loads (forces perpendicular to the axis), axial loads (thrust forces along the axis), and significant tilting moments (forces trying to tip the structure) simultaneously, making it exceptionally versatile for its size class. Its design prioritizes efficiency, longevity, and ease of integration into various machinery platforms.

The Critical Role of High Torque Slewing Drives

High torque slewing drives are fundamental to applications where significant rotational force is required at very low speeds. Unlike standard motors or gearboxes that might prioritize speed, these drives excel in generating immense rotational power even when movement is almost imperceptible. This capability is crucial for overcoming inertia in heavy structures, maintaining position under substantial wind or operational loads, and ensuring smooth, controlled motion without jerking or slippage. The high torque output is achieved through sophisticated gear reduction within the drive, typically utilizing a worm and worm wheel configuration. This design inherently provides high reduction ratios in a single stage, resulting in massive torque multiplication from a relatively compact input motor. Furthermore, worm gear sets often offer a self-locking characteristic under certain conditions, providing inherent braking and holding force without requiring additional external brakes, enhancing safety and system simplicity. The SP-M 0541 embodies this high-torque principle perfectly within the medium duty spectrum.

Industrial Robot Base Rotation: Precision Demands Met

The automation revolution hinges on the precision and reliability of industrial robots, and their base rotation is a foundational movement axis. This rotation dictates the robot's entire working envelope and positional accuracy. The demands here are extreme: smooth, absolutely precise angular positioning (often requiring arc-second accuracy), minimal backlash (play in the gear system) to prevent positioning drift, exceptional rigidity to maintain accuracy under dynamic loads during rapid movements, and high cyclic durability to withstand millions of operational cycles over years of service. Any vibration or inconsistency in the base rotation translates directly into inaccuracy at the robot's end effector. Slewing drives like the SP-M 0541 are uniquely suited for this role, especially for medium-sized articulated or SCARA robots. They provide the necessary rigidity, high torsional stiffness to resist twisting, and ultra-low backlash gearing. Advanced manufacturing techniques and meticulous assembly ensure the precision required for repeatable robotic tasks, while robust bearings and sealing protect the internal components from industrial contaminants, guaranteeing long-term performance in demanding factory environments.

Industrial Slewing Drives: The Workhorses of Rotation

Beyond robotics, industrial slewing drives are ubiquitous workhounds powering rotation across countless sectors. They are the silent force behind the smooth panning of surveillance cameras high on buildings, the precise alignment of massive satellite communication dishes tracking objects in space, the controlled rotation of wind turbine nacelles to face the wind optimally, the positioning of solar trackers following the sun's path for maximum energy capture, the slewing motion of material handling cranes and hoists on factory floors, and the rotation of heavy-duty industrial mixers and agitators. Their core value proposition lies in integrating multiple functions – gearing, bearing support, and often braking – into a single, compact, pre-engineered unit. This integration drastically simplifies design, reduces installation complexity, minimizes maintenance points, and enhances overall system reliability. Industrial environments demand ruggedness, resistance to shock loads, dust, moisture, and wide temperature variations. Slewing drives are specifically built to thrive in these harsh conditions, offering sealed lubrication systems and robust construction to deliver uninterrupted operation where standard components would fail.

Distinctive Features of the SP-M 0541 Medium Duty Gear Slewing Drive

The SP-M 0541 isn't just another slewing drive; it incorporates specific design elements that make it stand out in the medium duty category:

Optimized Gear Design: Features high-precision, hardened steel worm and worm wheel sets, often ground for superior surface finish, ensuring high efficiency, smooth operation, exceptionally low backlash, and extended service life under continuous load.

Robust Bearing System: Utilizes large-diameter, pre-loaded tapered roller bearings specifically chosen to handle the demanding combination of radial, axial, and moment loads typical in medium-duty applications, providing superior rigidity and longevity.

High Torque Density: Achieves impressive torque output relative to its compact size and weight, allowing for powerful rotation without excessive space requirements or system weight penalties.

Advanced Sealing: Incorporates multi-labyrinth seals combined with high-quality radial shaft seals (often Viton) to achieve high IP ratings (e.g., IP65, IP66), effectively excluding dust, water, and other contaminants, crucial for reliability in harsh industrial or outdoor settings.

Durable Housing: Manufactured from high-grade cast iron or fabricated steel, providing exceptional strength, vibration damping, and protection for internal components. Surfaces are typically treated or coated for corrosion resistance.

Precision Mounting Surfaces: Features precisely machined mounting flanges and base surfaces, ensuring accurate and rigid integration into the host structure, critical for maintaining system alignment and performance.

Maintenance-Friendly Design: Often includes accessible lubrication points (grease nipples) and, in some designs, inspection ports, facilitating easier maintenance routines to extend operational life.

Customization Options: While a standard model, the SP-M 0541 platform often allows for customization such as specific mounting hole patterns, special input shaft configurations (keyed, splined, hollow bore), integrated parking brakes, or specific seal variants to meet unique application requirements.

Smooth & Quiet Operation: Precision manufacturing and optimized gear geometry contribute to remarkably smooth and quiet running, even under heavy load, reducing noise pollution in work environments.

Diverse Applications Leveraging the SP-M 0541

The SP-M 0541's blend of power, precision, and compactness opens doors to a vast array of applications:

Robotics & Automation: Base rotation for medium-sized articulated robots, SCARA robots, and automated guided vehicle (AGV) turntables requiring precise positioning.

Material Handling: Rotation for palletizers, depalletizers, indexing tables, conveyor turntables, medium-duty jib cranes, and hoist rotation mechanisms within factories and warehouses.

Solar Energy: Driving single-axis solar trackers (azimuth or elevation rotation), significantly increasing energy yield by optimally positioning PV panels towards the sun throughout the day.

Satellite & Communication: Precisely positioning satellite TV antennas, VSAT terminals, and ground station communication dishes for accurate signal acquisition and tracking.

Surveillance & Security: Panning movement for heavy-duty PTZ (Pan-Tilt-Zoom) security cameras mounted on poles, buildings, or mobile platforms.

Medical & Rehabilitation Equipment: Providing controlled rotation in specialized patient lifting devices, therapy equipment, and imaging system components requiring smooth, reliable motion.

Packaging Machinery: Indexing and rotating heavy pallets, turntables for filling stations, or orienting products during packaging processes.

Test & Simulation Equipment: Providing controlled rotational motion in vibration test rigs, fatigue testing machines, and flight simulators where precision and load capacity are critical.

Agriculture & Forestry: Powering rotation in irrigation systems, fertilizer spreaders, or specialized forestry equipment booms.

Stage & Entertainment: Controlling the smooth rotation of lighting trusses, video screens, or performance platforms in theaters and event venues.

Factors Influencing the Price of the SP-M 0541

The cost of an SP-M 0541 slewing drive isn't fixed; it fluctuates based on several key factors:

Raw Material Costs: The price of steel, cast iron, specialized bearing steel, and high-performance sealing materials significantly impacts the base manufacturing cost. Market volatility in these commodities directly affects the final price.

Manufacturing Complexity & Precision: The high-precision machining required for gear teeth, bearing seats, and mounting surfaces, along with specialized heat treatment processes (like case hardening), demands advanced equipment and skilled labor, contributing substantially to the cost. Tighter tolerances (e.g., for ultra-low backlash) increase manufacturing expense.

Gear Quality & Specifications: The grade of steel used, the precision of the gear grinding (ground vs. cut gears), the specific gear ratio, and the torque rating all influence cost. Higher performance demands higher material and processing standards.

Bearing Quality & Configuration: The size, quality grade (ABEC rating), and type of tapered roller bearings used are major cost components. Premium bearings from renowned manufacturers add cost but enhance reliability and lifespan.

Sealing Standards: Achieving high IP ratings requires sophisticated sealing solutions, often involving multiple seal types and intricate labyrinth designs, which add to the manufacturing complexity and cost.

Customization: Any deviation from the standard SP-M 0541 configuration – such as special mounting flanges, unique input shaft designs, integrated brakes, specific paint finishes, or special seal materials for extreme environments – incurs additional engineering and production costs.

Order Volume & Supply Chain: Economies of scale apply; larger purchase orders typically secure better unit pricing. Global supply chain stability and logistics costs also factor into the final delivered price.

Supplier Value-Add: Technical support, comprehensive warranty coverage, testing certifications, and reliable after-sales service are value-added aspects that reputable suppliers incorporate, which can be reflected in the price.

Supplier of SP-M 0541 Medium Duty Gear Slewing Drive

When sourcing a critical component like the SP-M 0541 Medium Duty Gear Slewing Drive, partnering with a reliable and experienced manufacturer is paramount. LYRADRIVE stands as a leading force in the design, engineering, and production of high-performance slewing drives. We don't just supply components; we deliver engineered motion solutions. Our commitment is evident in our rigorous manufacturing processes, utilizing state-of-the-art CNC machining centers, precision gear grinding technology, and stringent quality control protocols at every stage – from raw material inspection to final performance testing. LYRADRIVE engineers possess deep expertise in gear mechanics, bearing technology, and tribology, allowing us to optimize the SP-M 0541 for real-world performance and durability. We understand the demanding environments our drives operate in and design accordingly. Beyond the standard SP-M 0541, LYRADRIVE excels in providing tailored solutions. Our engineering team works closely with customers to modify standard designs or create fully custom slewing drives when application requirements demand it. We offer comprehensive technical support, from initial selection guidance based on your load, speed, and environmental conditions to installation best practices and maintenance recommendations. Choosing LYRADRIVE means investing in a partnership built on quality, reliability, innovation, and dedicated support, ensuring your machinery benefits from optimal rotational performance for years to come. Contact LYRADRIVE today to discover how the SP-M 0541 can empower your next project.