The Ultimate Analysis of Industrial Joints: How Double Worm Slew Drives Conquer the Limits of Power and Precision

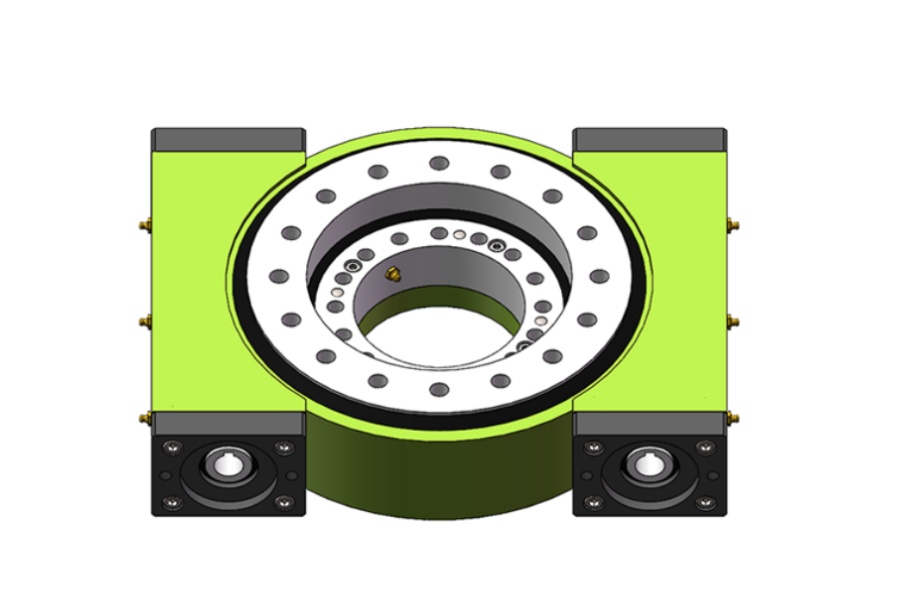

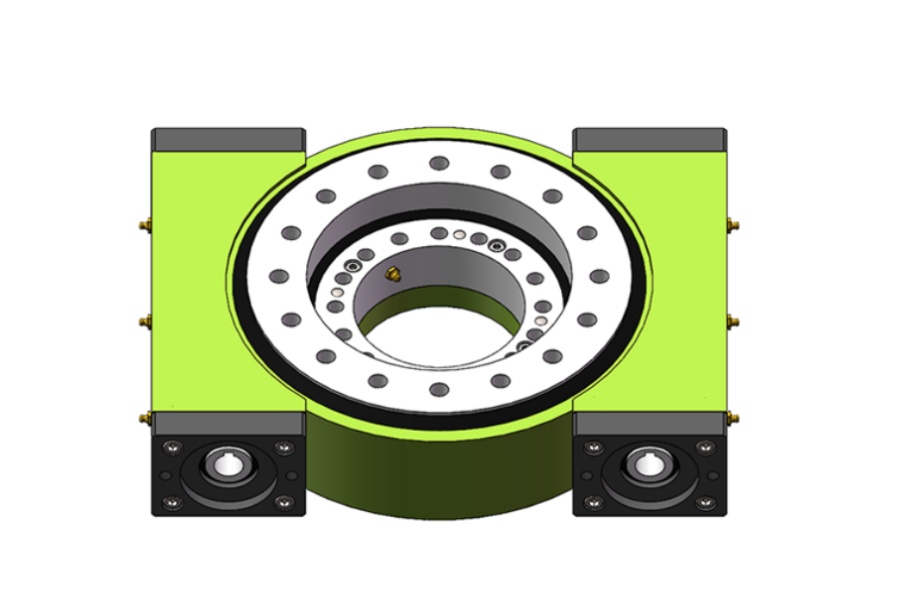

What is a Double Worm Slew Drive?

A double worm slew drive is a precision rotary reduction transmission mechanism. Its core structure breaks through the limitations of traditional single-worm designs by employing two identical worms symmetrically engaging a large worm wheel around its circumference. This layout not only significantly enhances the system’s overall load capacity and torque density but, more importantly, revolutionizes the solution to a critical challenge plaguing single-worm drives—backlash (lost motion)—achieving near-zero-clearance precision in power transmission and position control.

Core Secret: Torque Distribution and Synchronization Principles

The essence of the double-worm design lies in its intelligent torque distribution and forced synchronization mechanism:

Cooperative Load-Bearing: Input power is evenly distributed between the two worms. Each worm bears half of the total load torque, drastically reducing stress on individual worms and bearings, fundamentally improving the system’s overall rigidity and fatigue life.

Forced Synchronization: The two worms are connected via precision synchronizing gears or a rigid coupling shaft, ensuring they maintain identical rotation angles and speeds. This mandatory synchronization is key to eliminating motion errors, enabling both worms to act as a unified force on the worm wheel.

Bidirectional Preload: Crucially, the system applies an adjustable, oppositely directed axial preload force to the worms. One worm is pushed toward one flank of the worm wheel teeth, while the other is pressed against the opposite flank. Regardless of whether the worm wheel needs to rotate clockwise or counterclockwise, one worm is always in optimal engagement, maintaining tight contact with the worm wheel’s tooth surfaces.

How Does the Double Worm Slew Drive Achieve Revolutionary Backlash Elimination?

Traditional single-worm drives inevitably exhibit microscopic tooth clearance, causing lost motion errors during reversal. The double-worm design is born to solve this:

Preload Action: The opposing axial preload forces applied to the two worms force each to constantly press against the two working flanks of the worm wheel tooth profile.

Clearance Filling: When the system needs to change rotation direction, the "standby" worm (whose engagement side aligns with the upcoming rotation demand) is already in preloaded engagement. It instantly takes over power transmission, completely avoiding reverse idling due to backlash.

Seamless Switching: The synchronization mechanism ensures the two worms maintain precise phase alignment at all times, enabling smooth, instantaneous, and shock-free switching of power transmission. The result: Whether rotating forward or reverse, the output shaft responds immediately to input commands, achieving true "zero backlash" or "preload backlash elimination."

Double Worm Slew Drive: A Reliable Partner in Harsh Conditions

The outstanding performance of double worm slew drives shines especially bright in extreme environments:

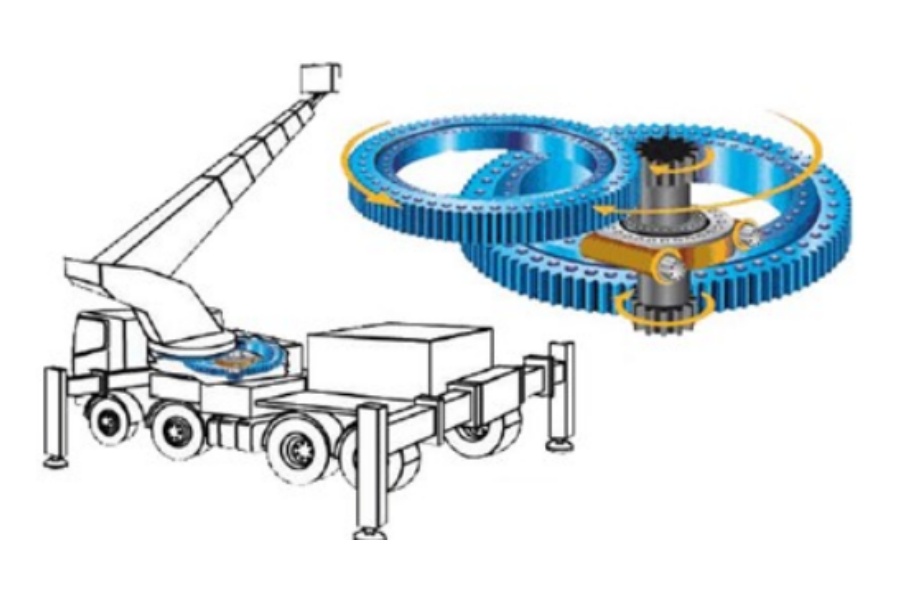

Massive Load Handling: In large port cranes, giant mining excavators, and tunnel boring machine cutterhead drives, it withstands hundreds or even thousands of tons of overturning moments and axial loads. Its robust dual-worm structure provides unparalleled support.

Precision Positioning: Satellite communication antennas, large radio telescopes, and precision radar turntables require sub-arc-minute pointing accuracy and stability. The zero-backlash characteristic ensures precise signal capture and tracking.

Environmental Challenges: Offshore oil platform cranes endure salt spray corrosion; wind turbine pitch systems face extreme temperatures, icing, and strong wind impacts; tunnel boring machines advance in high-pressure, humid slurry. Its rugged, sealed design and superior material selection ensure long-term reliable operation.

Safety First: In amusement rides, cableway drives, and other safety-critical applications, its inherent self-locking property (with specific lead angles) and ultra-high reliability are vital barriers against accidental reversal and key safeguards for human safety.

Product Features of Double Worm Slew Drives

The core advantages of double worm slew drives make them stand out:

Zero/Very Low Backlash: Core advantage for precise position control and repeatability.

Ultra-High Rigidity & Load Capacity: Dual worms share the load, offering incredible capability in a compact structure.

Excellent Impact Resistance: Symmetrical design effectively absorbs shock loads, protecting the system.

Superior Precision & Smoothness: Synchronization ensures smooth motion, reducing vibration and noise.

High Power Density: Delivers enormous output torque within limited space.

Long Life & High Reliability: Low-stress design and load-sharing extend the life of critical components.

Compact Integration: Typically integrates bearings, seals, and drive source interfaces for easy installation.

Bidirectional Self-Locking (Optional): Specific lead angle designs can provide safety self-locking.

Price Influencing Factors for Double Worm Slew Drives

The price of double worm slew drives is affected by multiple factors:

Size Specifications: Worm wheel diameter, module, and overall dimensions directly impact material usage and machining costs. Larger sizes mean higher prices.

Torque/Load Rating: Higher designed overturning moments, axial forces, and radial loads demand stronger materials, better heat treatment, and higher-grade bearings, significantly increasing costs.

Precision Grade: Stricter backlash control (e.g., <1 arc-minute) and transmission error requirements demand higher gear machining precision, assembly techniques, and inspection methods, raising costs accordingly.

Materials & Processes: Worm gears and worms made of high-performance alloy steel (e.g., carburized and hardened alloy steel) or special bronze; brand and precision grade of key bearings; surface treatments (e.g., hardening, coating) greatly impact cost and lifespan.

Sealing & Protection Rating: High IP ratings (e.g., IP67/IP69K), special seal materials (oil-resistant, corrosion-resistant, temperature-resistant) for harsh environments increase costs.

Integration Level & Interfaces: Whether integrated with motors, brakes, encoders, or gearboxes; type of mounting flange and output interface provided. Higher integration and customization mean higher prices.

Brand & Technology: Premiums come with established brands' technical expertise, quality control systems, and after-sales service. Products with core backlash-elimination patents hold higher value.

Customization Level: Standard products are relatively cheaper. Non-standard designs (special sizes, interfaces, performance parameters) require extra R&D and tooling investment, leading to significantly higher prices.

Quantity: Bulk purchases typically secure better unit prices.

Choosing Double Worm: Choosing Future Competitiveness

The double worm slew drive represents the pinnacle of technology in high-end precision transmission. Its revolutionary dual-worm preload backlash elimination design perfectly resolves the age-old dilemma of balancing power and precision. From sky-supporting giant booms to star-guiding "eyes of heaven," from mountain-splitting tools to deep-diving pioneers, in battlefields demanding extreme reliability, precision, and load capacity, the double worm slew drive silently plays an indispensable, critical role.

Suppliers of Double Worm Slew Drives

When your equipment faces extreme challenges and needs a powerful, precise "industrial joint," the double worm slew drive will be your reliable partner to break through bottlenecks and conquer the future. Explore its potential and unlock new heights of equipment performance.

Are you searching for the ultimate transmission solution to completely eliminate backlash and enhance load capacity and precision? Contact LYRADRIVE now for professional double worm slew drive selection advice and customized solutions!