The Power of Two: A Complete Guide to the Double Worm Slew Drive

When your machinery needs to handle immense loads and deliver precise, powerful rotation, you need a drive that's up to the challenge. Enter the Double Worm Slew Drive. This robust mechanism is engineered to provide unparalleled strength and reliability where standard drives fall short. At LyraDrive, we specialize in designing and manufacturing advanced slewing solutions like this to power the most demanding applications.

What is Double Worm Slew Drive?

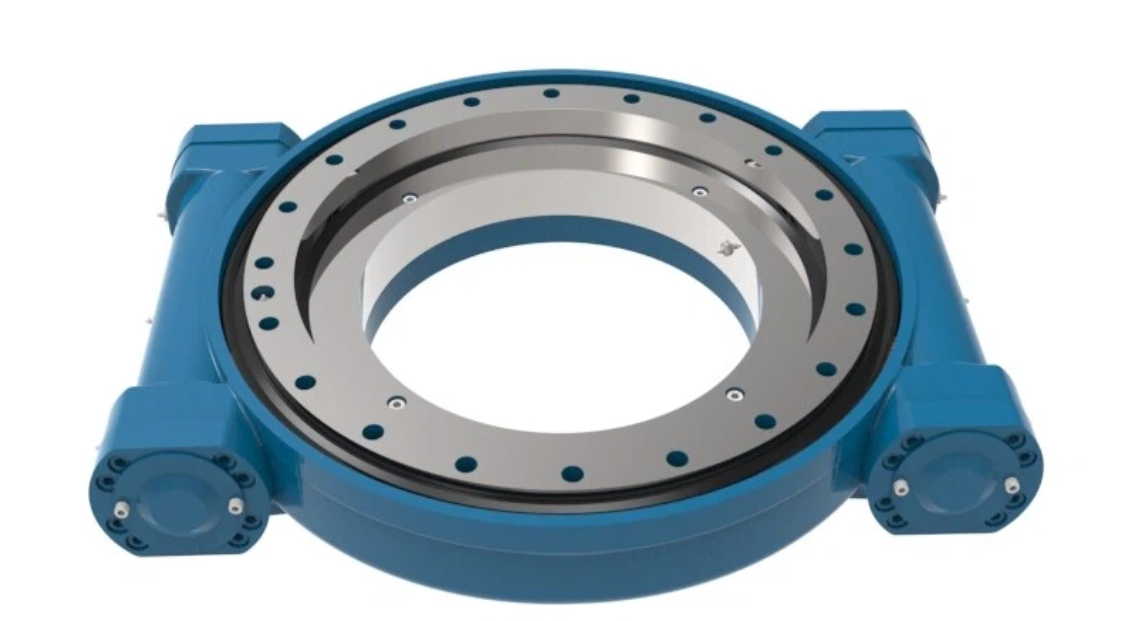

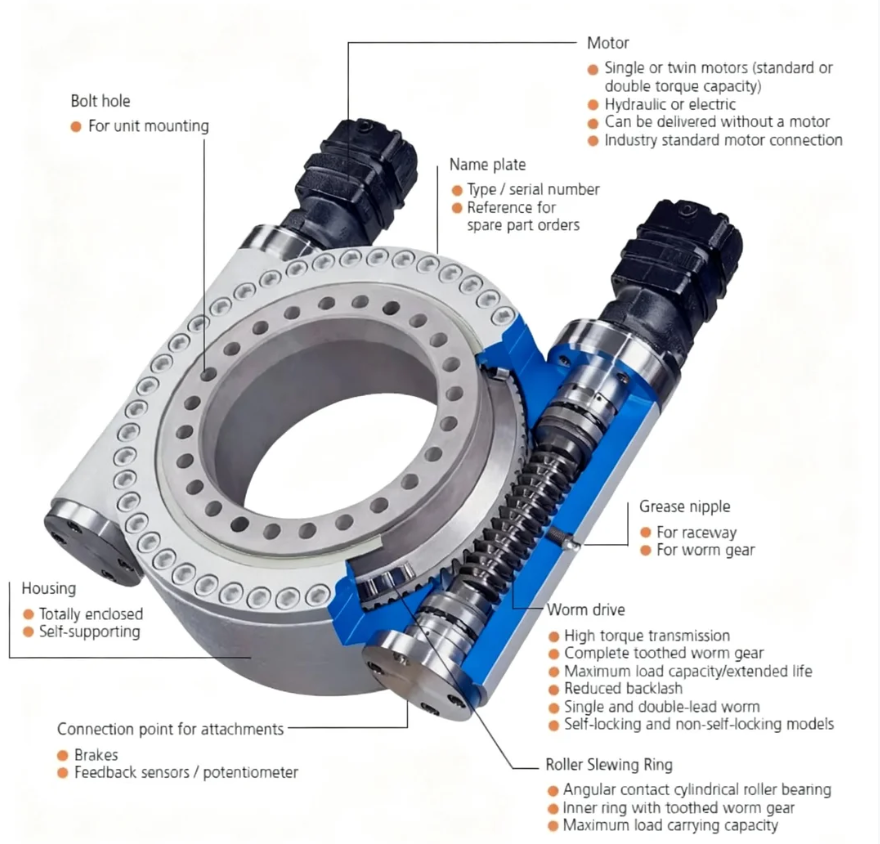

A Double Worm Slew Drive is an advanced rotational drive system. It consists of a central worm gear that is simultaneously driven by two separate worm screws, housed within a sturdy outer casing along with a motor. This dual-input design is the key to its superior performance.

The primary difference from a Single Worm Slew Drive lies in its power delivery and structural integrity. Think of it this way: a single worm drive is like lifting a heavy beam with one strong arm, while a double worm drive uses two arms working in perfect sync. This dual engagement means the load is distributed evenly across two points, drastically reducing stress on individual components.

Specifically, this leads to:

Doubled Force Transmission: Two worms share the driving force, allowing for significantly higher torque output without increasing the size of a single worm.

Balanced Load & Reduced Deformation: The symmetrical force application prevents casing distortion and bearing misalignment, which are common failure points in single-worm designs under heavy loads.

Inherent Redundancy: While not a fail-safe feature by default, the dual-worm design offers a more robust structure that is less prone to catastrophic failure from a single point of stress.

How Does Double Worm Slew Drive Work?

The principle is simple yet brilliant. The motor transmits power to the two worm screws. These screws are positioned opposite each other and mesh with the teeth of the central worm gear ring. As they rotate, they "walk" the gear ring around, creating smooth, powerful, and controlled rotational movement.

The core of this system is the specially designed slewing bearing. In a double worm drive, this bearing functionally acts like a double-row crossed roller bearing. This means it has two independent rows of cylindrical rollers arranged at 90-degree angles to each other. This configuration is perfect for handling the complex loads—axial (thrust), radial (side), and moment (tilting)—generated by the dual-drive system, ensuring high precision and exceptional load capacity.

Advantages of the Double Worm Slew Drive

Choosing a double worm drive brings decisive benefits for heavy-duty operations:

Exceptional Load Capacity & Higher Output Torque: It is uniquely suited for ultra-heavy loads where single worm drives would risk jamming, excessive wear, or failure.

Compact & Space-Saving Structure: Despite its power, its design is often more integrated and compact than achieving similar torque with a single large worm, saving valuable space in your machine design.

Smooth, Stable Operation: The balanced force from two worms eliminates the "cogging" or judder that can occur in single-worm drives under variable loads, ensuring exceptionally smooth rotation.

Enhanced Rigidity & Reduced Vibration: The dual-support system dramatically increases the overall stiffness of the drive, minimizing deflection, vibration, and operational noise.

Optimized Bearing Life: By evenly distributing forces, it prevents uneven wear on the slewing bearing, leading to longer service life and reduced maintenance.

Application of Double Worm Enclosed Slewing Drive

This drive is the preferred choice for equipment where failure is not an option and performance is critical.

Heavy-Duty Platform Transporters & SPMTs: For multi-axle trailers carrying hundreds of tons (like turbines or bridge sections), the double worm drive provides the powerful, reliable steering needed for precise maneuvering.

Gantry & Bridge Lifting Equipment: Modernizing a traditional rail-based gantry crane with slew drives on its legs transforms it into a mobile, rotating lifter. This can reduce the required number of cranes in a work area by up to 75%, slashing costs and boosting efficiency.

Large Industrial Manipulators & Indexing Tables: In automation, these drives provide the muscle for rotating heavy assemblies or workpieces with pinpoint accuracy.

Specialized Mining & Construction Machinery: Found in robust applications like heavy-duty excavator swing mechanisms or large drill rigs where continuous high-torque rotation is essential.

LyraDrive: Your Smart Solution Partner

Selecting the right drive is complex. At LyraDrive, we don't just sell components,such as slew drives and slewing bearings; we provide engineered solutions. With our deep expertise in both slew drives and slewing bearings, we ensure perfect system integration. We offer:

Expert Application Engineering: We help you determine if a double worm drive is the optimal choice for your specific load, speed, and duty cycle requirements.

Custom Configuration: We can tailor dimensions, sealing (IP ratings), lubrication, and mounting interfaces to fit seamlessly into your machine design.

Full Technical Support: From initial design consultation to installation guidance and after-sales support, our team is here to ensure your project's success.

Frequently Asked Questions (FAQ)

Q1: When should I definitely choose a double worm drive over a single worm drive?

A: Choose a double worm drive when dealing with very high moment loads and torque requirements, or when you need maximum rigidity and smoothness in heavy-duty, precision applications. If a single worm drive calculation shows it is operating near its limit, it's time to consider the double worm solution.

Q2: Is a double worm drive twice as powerful as a single worm drive?

A: Not simply twice, but it achieves significantly higher torque in a comparable size. The power increase is substantial because the load is shared, allowing each worm to operate efficiently without being overstressed.

Q3: Does it require two motors?

A: Typically, no. Most designs use a single motor with a gearbox or timing belts to synchronously drive both worm screws, ensuring perfectly coordinated movement.

Q4: Is maintenance more complicated?

A: Not necessarily. While it has two worms to lubricate, the maintenance schedule is similar. Its robust design often leads to longer intervals between servicing. LyraDrive provides clear maintenance manuals for all our products.

Q5: Can it be used in outdoor or harsh environments?

A: Absolutely. At LyraDrive, we can equip our drives with multi-labyrinth seals, special coatings, and grease purging systems to withstand dust, moisture, and extreme temperatures common in mining, construction, and marine applications.

Q6: What about cost? Is it much more expensive?

A: While the initial unit cost is higher, the Total Cost of Ownership (TCO) is often lower for heavy-duty applications. You benefit from fewer breakdowns, less downtime, longer component life, and higher reliability, which saves money in the long run.

Q7: Can LyraDrive provide a custom double worm drive for a unique application?

A: Yes, customization is our strength. We regularly engineer drives with specific bolt patterns, special flange mounts, integrated sensors, or unique gear ratios to solve complex engineering challenges.

Q8: How do I get started with specifying a drive for my project?

A: Contact the LyraDrive engineering team early in your design process. Provide us with your key parameters: total load (axial, radial, moment), required speed, rotation range, and environmental conditions. We will recommend the optimal solution and provide detailed 3D models for your integration.

Ready to harness the robust power and reliability of a double worm slew drive for your next project? The engineers at LyraDrive are ready to collaborate with you. Contact us today to discuss your application and receive a smart, customized solution that ensures your machinery performs at its peak, year after year