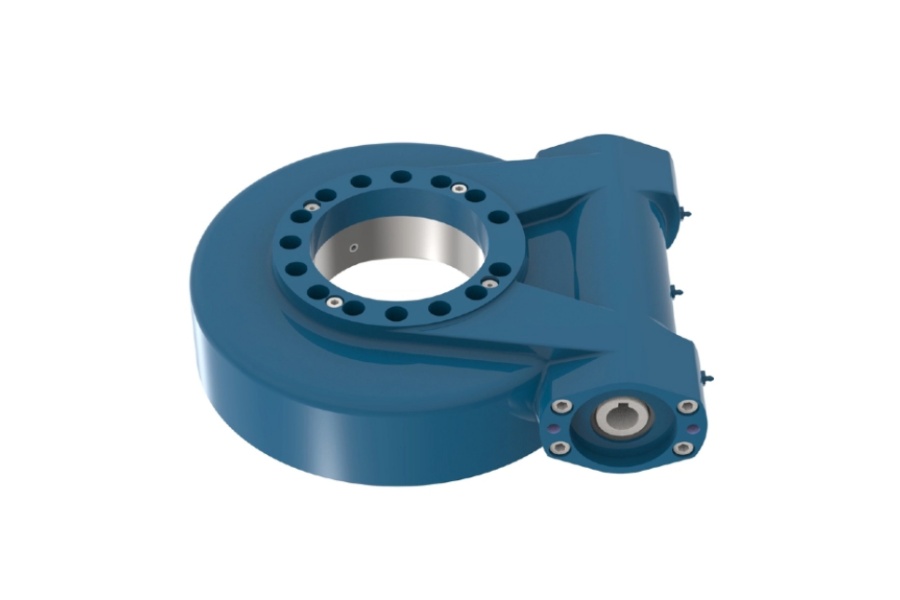

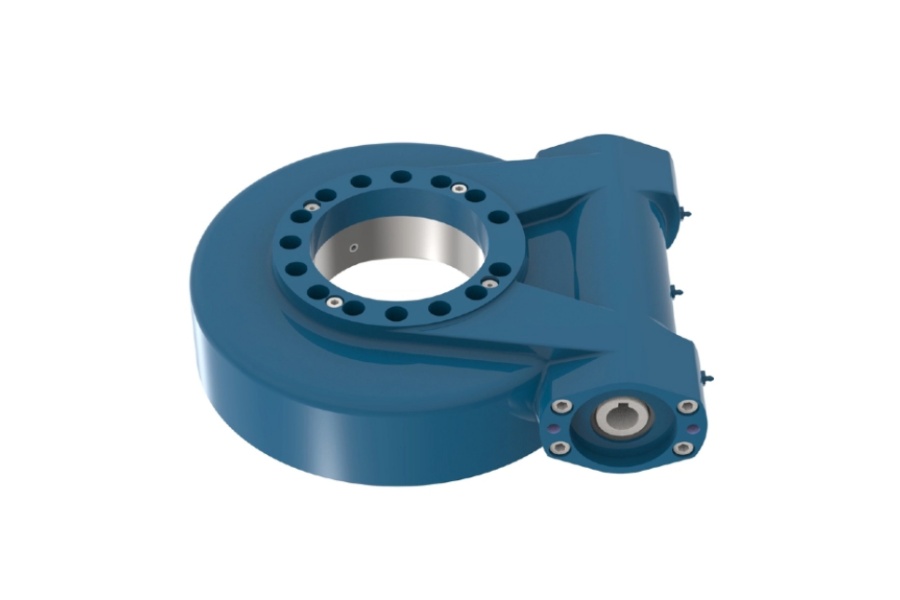

The Enveloping Slewing Drive SE9 Power and Precision

What is Enveloping Slewing Drive SE9

Enveloping Slewing Drive SE9 is a specific model of slewing bearing integrated with a high-efficiency enveloping worm gear mechanism. Unlike standard single enveloping drives, the SE9 features a double enveloping design where both the worm and the gear wheel feature concave profiles that wrap around each other. This intricate geometry dramatically increases the contact area between the worm threads and the gear teeth compared to conventional designs. The result is a drive capable of transmitting very high output torque (6.5 kN.m) and handling substantial tilting moments (33.9 kN.m) and holding moments (38.7 kN.m) relative to its compact size and weight (49 kg). It incorporates precision bearings capable of supporting high static axial (338 kN) and radial (135 kN) loads, along with significant dynamic axial (81 kN) and radial (71 kN) capacities. Available in various configurations (SEA9, SEB9, PE9) and offering a standard 61:1 gear ratio with tracking precision ≤0.17°, the SE9 provides smooth, controlled rotation with minimal backlash. Its defining characteristic is achieving this high power and load capacity within an exceptionally space-saving envelope.

Reasons and Solutions for Noise in Slewing Drive Operation

Operational noise in a slewing drive is often a key indicator of potential issues or improper conditions. Understanding the causes is crucial for timely intervention and maintenance:

Insufficient or Degraded Lubrication: The primary cause of noise is often lack of proper lubrication or grease that has broken down, hardened, or become contaminated. Inadequate lubrication leads to increased metal-to-metal contact and friction, resulting in grinding, whining, or squealing sounds.

Solution: Implement a strict, manufacturer-recommended lubrication schedule using the specified high-quality, extreme-pressure (EP) grease. Ensure grease points are accessible and purging is done correctly to remove old grease and contaminants. Regularly inspect grease condition.

Wear and Tear: Over time and under heavy loads, components like gear teeth (worm and wheel), bearing raceways, and rolling elements can wear. Pitting, spalling, or scoring on gear teeth or bearings creates irregular surfaces, leading to rumbling, grinding, or clicking noises, especially under load.

Solution: Regular inspection for wear is essential. Monitor noise levels and vibration trends. If wear is detected early, adjustments or component replacement might be possible. Severe wear typically necessitates drive overhaul or replacement.

Misalignment or Improper Installation: If the slewing drive is not mounted on a perfectly flat, rigid surface or if it is subjected to external forces causing misalignment (exceeding its tilting moment capacity), internal components experience uneven loading and stress. This can cause binding, groaning, or irregular grinding noises.

Solution: Ensure strict adherence to mounting specifications regarding surface flatness, bolt torque sequences, and alignment during installation. Verify the structure can adequately support the drive without deflection under maximum load.

Contamination: Ingress of abrasive particles like dirt, sand, or metal shavings into the gear meshing area or bearings acts like lapping compound, accelerating wear and creating grinding or crunching noises.

Solution: Ensure seals are intact and effective. Maintain clean working environments during installation and maintenance. Use proper sealing kits during any service that exposes internal components.

Backlash Issues: While some minimal backlash is inherent, excessive backlash due to wear or improper initial setup can cause a distinctive "clunking" or "knocking" sound, particularly during direction reversals or when load shifts suddenly.

Solution: Check and adjust backlash during installation according to manufacturer specs. Monitor backlash over time as an indicator of wear. Excessive backlash usually signifies significant wear requiring attention.

Loose Mounting Bolts or Hardware: Vibration during operation can cause mounting bolts or internal hardware to loosen, leading to rattling, knocking, or shifting sounds and potentially causing misalignment or catastrophic failure.

Solution: Perform regular torque checks on all critical mounting bolts according to the specified sequence and values. Use appropriate thread-locking compounds where recommended.

Key Features of the Enveloping Slewing Drive SE9

The SE9 stands out due to a combination of advanced engineering features delivering superior performance:

Exceptional Power Density: The double enveloping worm gear design is the cornerstone, enabling the SE9 to generate a substantial 6.5 kN.m output torque and withstand high tilting moments (33.9 kN.m) and holding moments (38.7 kN.m) within a compact footprint and weighing only 49 kg. This makes it ideal where space and weight are constrained.

High Load Capacity: Engineered with robust internal bearings, the SE9 handles significant static axial loads (338 kN) and static radial loads (135 kN), along with considerable dynamic axial (81 kN) and dynamic radial (71 kN) capacities, providing stability under varying operational stresses.

Precision and Low Backlash: The enveloping gear mesh offers inherently smoother operation and significantly reduced backlash compared to standard worm gears. Combined with precision manufacturing, this results in highly controlled motion with a tracking precision of ≤0.17°, crucial for applications requiring accurate positioning.

High Efficiency: The multi-point contact of the double enveloping design distributes load more evenly, reducing localized stress and friction losses. This translates into higher mechanical efficiency compared to single enveloping or crossed roller bearing drives, especially under high torque loads.

High Rigidity and Stiffness: The combination of the enveloping gear mesh and the integrated slewing bearing structure creates an extremely rigid unit. This minimizes deflection under load, ensuring precise motion control and maintaining gear mesh alignment for optimal performance and longevity.

Self-Locking Capability (Standard Ratio): The standard 61:1 gear ratio provides a high mechanical advantage. The friction angle inherent in the enveloping worm design often results in a self-locking characteristic, preventing back-driving and holding position securely without needing an external brake in many scenarios, enhancing safety.

Integrated Design: Combining the bearing, gearing, housing, and often the mounting structure into a single, sealed unit simplifies system design, reduces the number of components, eases installation, and protects internal mechanisms.

Durability and Reliability: Manufactured from high-grade materials and subjected to rigorous quality control, the SE9 is built for long service life in demanding industrial environments when properly maintained.

Typical Applications for the Enveloping Slewing Drive SE9

The SE9's blend of compact size, high torque, significant load capacity, and precision makes it exceptionally versatile across numerous industries:

Solar Tracking Systems: A prime application. The SE9 provides the precise, robust, and reliable rotational movement required for single-axis and dual-axis solar trackers, optimizing panel alignment with the sun for maximum energy capture. Its self-locking capability is particularly beneficial here.

Material Handling & Cranes: Used in the slew mechanism of compact crane jibs, manipulator arms, lifting platforms, and rotating sections of conveyor systems where controlled rotation under load is essential within limited space envelopes.

Construction Equipment: Powers rotation in compact excavator attachments, drilling equipment attachments, small concrete mixer drums, and positioning mechanisms where high torque in a small package is critical.

Wind Energy: Employed in yaw and pitch adjustment mechanisms for smaller wind turbines or auxiliary systems within larger turbines, providing precise blade angle control or nacelle positioning.

Robotics and Automation: Ideal for heavy-duty robotic joints, automated welding positioners, and indexing tables requiring high torque, rigidity, and precise angular positioning in industrial automation settings.

Medical and Rehabilitation Equipment: Used in sophisticated patient lifting systems, treatment chair positioning, and rehabilitation apparatus where smooth, powerful, and controlled rotation is necessary.

Defense and Aerospace: Applied in radar and antenna positioning systems, turret rotation for smaller vehicles or equipment, and other applications demanding reliability, precision, and compactness.

Packaging and Processing Machinery: Powers rotating stages, indexing units, and product handling arms in machines where space is limited but robust motion is required.

Agricultural Machinery: Used in guidance systems, rotating sprayer booms, and positioning mechanisms on agricultural equipment.

Factors Influencing Enveloping Slewing Drive SE9 Pricing

The cost of an Enveloping Slewing Drive SE9 is not fixed and varies based on several key factors:

Order Quantity: Significant economies of scale apply. Bulk purchases typically command substantial per-unit cost reductions compared to single-unit or small-batch orders.

Material Costs: Fluctuations in the global prices of high-grade steel alloys used for gears, bearings, and housings directly impact manufacturing costs. Specialty coatings or treatments add cost.

Manufacturing Complexity: The double enveloping gear profile requires sophisticated CNC machining, specialized grinding equipment, and stringent quality control processes, contributing significantly to the base cost. Precision bearing integration adds further complexity.

Configuration and Customization: The base SE9 model price varies slightly with standard configurations (SEA9, SEB9, PE9). Any customization dramatically increases cost:

Non-standard gear ratios

Special sealing arrangements (e.g., high IP ratings, specific seal materials)

Unique mounting flanges or bolt patterns

Special surface treatments (corrosion protection like deep galvanizing, specialized paints)

Modified lubrication systems (e.g., central lubrication ports)

Integration of sensors (e.g., torque, position, temperature)

Quality and Precision Requirements: Drives manufactured to meet exceptionally tight tolerances (beyond the standard ≤0.17° precision) or certified to specific industry standards (e.g., ISO, DNV) incur higher production and verification costs.

Bearing Specifications: While standard bearings are used, requests for higher-grade bearing components (e.g., C3/C4 clearance, different ball/roller materials) affect price.

Geographic Market and Logistics: Shipping costs, import duties, taxes, and local market dynamics influence the final landed price for the customer. Regional manufacturing hubs can sometimes offer advantages.

Supplier Value-Added Services: Costs may reflect additional services like comprehensive technical support, detailed application engineering, extensive testing reports, or extended warranty terms.

Market Demand: Supply chain dynamics and overall market demand for slewing drives can influence pricing stability.

Reliable Supplier of the Enveloping Slewing Drive SE9

LYRADRIVE stands as a prominent manufacturer and supplier specializing in high-performance slewing drives, including the advanced Enveloping Slewing Drive SE9 series. Leveraging expertise in precision gear manufacturing and bearing integration, LYRADRIVE focuses on delivering robust, reliable, and efficient motion solutions. They offer the SE9 in its standard high-performing configurations and possess the engineering capability to provide customized variants tailored to meet specific application challenges and environmental demands. LYRADRIVE emphasizes quality control throughout the manufacturing process to ensure the SE9 meets the stringent requirements of industries like solar energy, material handling, construction, and automation. Their support typically includes technical guidance for selection, integration, and maintenance, aiming to provide a complete solution beyond just the physical drive unit. For applications demanding compact size coupled with high torque, significant load capacity, and precision rotation, LYRADRIVE's Enveloping Slewing Drive SE9 represents a technologically advanced and dependable choice.