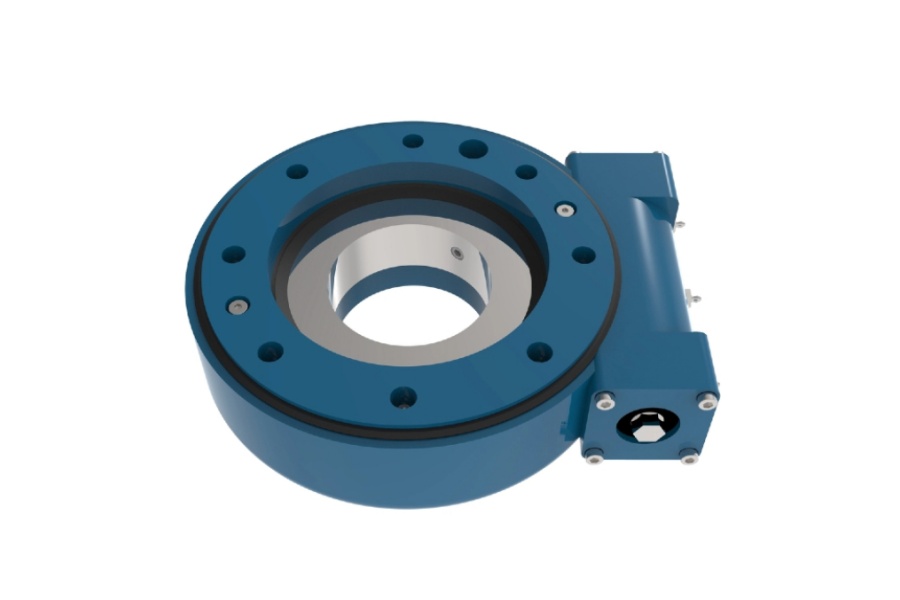

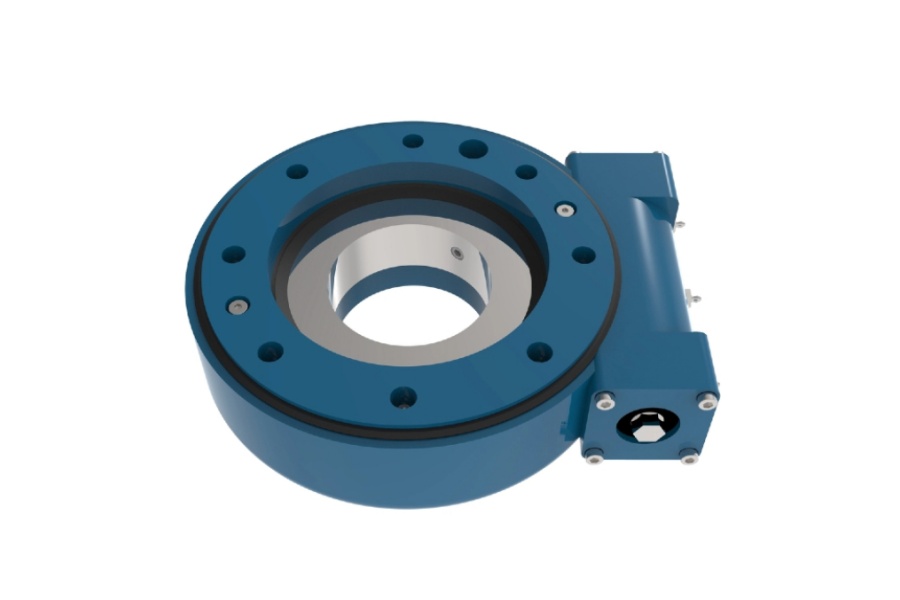

High-Torque Enveloping Slewing Drive SE7

What is Enveloping Slewing Drive SE7?

Enveloping Slewing Drive SE7 is a sophisticated, self-contained rotary drive system comprising a robust housing, a hardened worm gear, and a uniquely designed enveloping worm. This advanced configuration allows multiple gear teeth (typically 4 to 5) to engage simultaneously, drastically increasing the drive's output torque, tilting moment capacity, and holding torque compared to standard designs. Its defining characteristic is the "enveloping" action, where the worm partially wraps around the gear, maximizing contact area and load distribution. This integrated system excels at handling combined loads – significant axial and radial forces coupled with substantial tilting moments – all while providing inherent self-locking safety. Encased within a protective housing offering enhanced sealing (IP65 rated), the SE7 is built to withstand harsh environments, making it an indispensable solution for industries requiring robust, precise, and fail-safe rotational movement under heavy loads.

How to Choose the Right Precision Grade for Your Slewing Drive Application

Selecting the optimal precision grade for a slewing drive is critical for ensuring system performance, longevity, and cost-effectiveness. The precision grade primarily refers to the drive's ability to maintain positional accuracy and minimize backlash during operation. Consider these key factors:

Application Requirements: What level of positional accuracy is absolutely necessary? High-precision tasks like solar tracking, robotic positioning, or precision machining demand drives with very low backlash (e.g., ≤0.07° like some SE7 variants). Applications like general material handling or basic positioning might tolerate higher backlash (e.g., ≤0.2°).

Load Dynamics: How dynamic are the loads? Applications involving high inertial loads, rapid starts/stops, or reversing directions benefit significantly from higher precision (lower backlash) drives. Backlash can cause jarring impacts, vibration, and reduced control during load reversals, accelerating wear.

Motion Control System: The capabilities of your motors and controllers influence precision needs. High-resolution encoders and sophisticated control algorithms can sometimes compensate for moderate drive backlash, but inherently precise drives provide a more stable foundation and reduce control complexity.

Environmental Factors: Harsh environments (temperature extremes, vibration, contamination) can affect precision over time. A drive designed for higher initial precision (like the SE7) often incorporates features (superior gear meshing, robust bearings) that better maintain accuracy under stress.

Cost vs. Performance: Higher precision grades typically involve more stringent manufacturing tolerances, specialized materials, and advanced design features, increasing cost. Carefully evaluate if the performance gains justify the additional investment for your specific use case. Avoid over-specifying precision where it's not needed, but never compromise on critical safety or performance requirements.

Long-Term Wear: Precision inherently degrades over time due to wear. Choosing a drive with a higher initial precision grade provides a longer service life before wear pushes backlash beyond acceptable limits. The SE7's enveloping design promotes even wear distribution, contributing to sustained precision.

For the Enveloping Slewing Drive SE7, precision grades are clearly specified (e.g., ≤0.2°, ≤0.1°, or ≤0.07°), allowing engineers to match the drive precisely to the demands of their application, balancing performance needs with operational costs.

Key Features of the Enveloping Slewing Drive SE7

The SE7 stands out in the heavy-duty rotary drive market due to its exceptional blend of strength, safety, and environmental resilience, engineered directly into its core design:

Unmatched Torque & Load Capacity: The enveloping worm design is the cornerstone of its strength. By engaging multiple gear teeth simultaneously, the SE7 achieves remarkably high output torque (1500 N.m), tilting moment capacity (13,500 N.m), and holding torque (10,400 N.m). It handles substantial static axial (133 kN) and radial (53 kN) loads, along with significant dynamic axial (32 kN) and radial (28 kN) loads.

Inherent Self-Locking Safety: This critical safety feature is a direct result of the worm gear geometry. When drive power is removed or the motor stops, the friction within the worm gear interface prevents back-driving. This ensures loads remain securely locked in position, preventing uncontrolled movement – a vital requirement for personnel safety in applications like aerial platforms or crane jibs.

Robust IP65 Sealing: Engineered for harsh realities, the SE7 features superior sealing that achieves an IP65 rating. This signifies complete protection against dust ingress and protection against low-pressure water jets from any direction, making it ideal for outdoor use, dusty construction sites, or industrial washdown environments where traditional drives might fail.

High Precision Rotation: Available in precision grades down to ≤0.07°, the SE7 delivers smooth, accurate, and predictable rotation. This precision is essential for applications demanding exact positioning, such as aligning solar panels for optimal energy capture or precisely maneuvering heavy loads with cranes.

Optimized Gear Ratio (73:1): The standard high reduction ratio provides significant speed reduction and torque multiplication from a compact input motor, enabling powerful rotational control in a space-efficient package.

Durable Construction & Materials: Built for longevity under demanding conditions, the SE7 utilizes high-quality alloy steels for gears and worms, paired with heavy-duty bearings. This ensures resistance to wear, fatigue, and deformation under continuous heavy loading.

Enhanced Protection Over Standard S-Series: The SE7 series specifically offers superior sealing performance compared to conventional S-series slewing drives, directly addressing the need for reliability in challenging environments.

Compact Design & Manageable Weight (25 kg): Despite its impressive power density, the SE7 maintains a relatively compact form factor and weight, simplifying integration into machinery designs where space and weight are considerations.

Enveloping Slewing Drive SE7 Applications

The combination of high torque, precision, self-locking safety, and environmental protection makes the SE7 indispensable across numerous demanding sectors:

Aerial Work Platforms (AWPs): Provides the reliable, high-torque rotation needed for booms and platforms. The self-locking feature is paramount for operator safety, preventing unintended movement if power is interrupted while personnel are elevated.

Crane Systems: Integral to mobile cranes (truck-mounted, rough-terrain) and certain fixed crane configurations for rotating the boom or superstructure. Handles the substantial tilting moments and axial loads encountered during lifting operations while offering precise positioning control.

Solar Tracking Systems: Powers the precise movement required to orient solar panels optimally throughout the day, maximizing energy capture. High precision ensures accurate sun-following, while self-locking holds position without constant motor power, improving energy efficiency.

Wind Turbines: Used for critical functions like yaw control (rotating the nacelle to face the wind) and potentially pitch control (adjusting blade angle). Must withstand extreme weather, high loads, and provide reliable, maintenance-intensive operation.

Heavy Equipment: Found in excavators, wheel loaders, and similar machinery for rotating attachments (e.g., grapples, augers) or upper structures. Delivers the brute force and durability needed in rugged, high-vibration environments.

Rotary Tables & Indexing Platforms: Provides precise and powerful rotation for positioning workpieces in automated manufacturing, machining centers, welding cells, and assembly lines within industries like metalworking, automotive, and packaging.

Material Handling & Automation: Powers rotating sections of conveyors, palletizers, robotic arms, and other automated systems requiring robust and reliable rotary motion under load.

Specialized Machinery: Utilized in diverse equipment such as radar antennas, stage machinery, tunnel boring machines, and medical imaging devices where controlled, powerful rotation is essential.

Factors Influencing Enveloping Slewing Drive SE7 Pricing

The cost of an Enveloping Slewing Drive SE7 is not fixed and depends on several interrelated factors:

Specification & Load Ratings: Drives configured for higher torque outputs, increased axial/radial load capacities, or larger tilting moments typically require larger components, more material, and enhanced manufacturing processes, increasing cost. The standard SE7 specs represent a baseline; exceeding them adds cost.

Precision Grade: Achieving lower backlash tolerances (e.g., ≤0.07° vs. ≤0.2°) demands significantly higher manufacturing precision, specialized grinding processes, and potentially tighter quality control, resulting in a higher price point.

Material Selection: The standard uses high-quality alloy steels. Upgrades to higher grades of steel, specialized heat treatments for extreme hardness or toughness, or corrosion-resistant coatings (like zinc-nickel) add to the material and processing costs.

Sealing & Protection: While IP65 is standard for the SE7 series, requests for even higher ingress protection (e.g., IP66/IP67) or specialized seals resistant to specific chemicals, extreme temperatures, or high-pressure washdowns involve more complex sealing solutions and materials, impacting price.

Customization: Any deviation from the standard SE7 design incurs engineering and production costs. This includes:

Custom Gear Ratios: Developing non-standard ratios requires new gear design and manufacturing.

Modified Mounting Interfaces: Flange patterns, bolt hole configurations, or shaft outputs tailored to a specific machine.

Special Bearings: Upgrading to different bearing types (e.g., crossed rollers for higher moment capacity) or higher precision classes.

Integration of Accessories: Adding encoders, brakes (beyond the inherent self-lock), special lubrication ports, or custom paint.

Order Volume: Larger quantities typically benefit from economies of scale in manufacturing, material procurement, and logistics, leading to lower per-unit costs compared to single-unit or small-batch orders.

Market Dynamics: Fluctuations in the cost of raw materials (steel, alloys), energy, and logistics (shipping) can influence the final price. Global supply chain conditions also play a role.

Supplier Value-Add: The level of technical support, engineering services, warranty coverage, testing, and after-sales service provided by the supplier contributes to the overall value proposition and can be reflected in the price.

Supplier of Enveloping Slewing Drive SE7

LYRADRIVE is a recognized leader in the design, engineering, and manufacturing of high-performance slewing drives, including the advanced Enveloping Slewing Drive SE7 series. With a strong focus on innovation, quality, and reliability, LYRADRIVE leverages deep engineering expertise to develop solutions tailored to meet the rigorous demands of diverse global industries. Their commitment extends beyond standard products, offering significant customization capabilities to ensure the SE7 perfectly integrates into specific application requirements. LYRADRIVE maintains stringent quality control throughout the manufacturing process, ensuring every drive delivers the promised performance, durability, and safety. Supported by comprehensive technical service, LYRADRIVE positions itself as a trusted partner for businesses seeking robust and dependable rotary motion solutions.