The Critical Role of Lubricating Grease in Spur Gear Slew Drive Performance

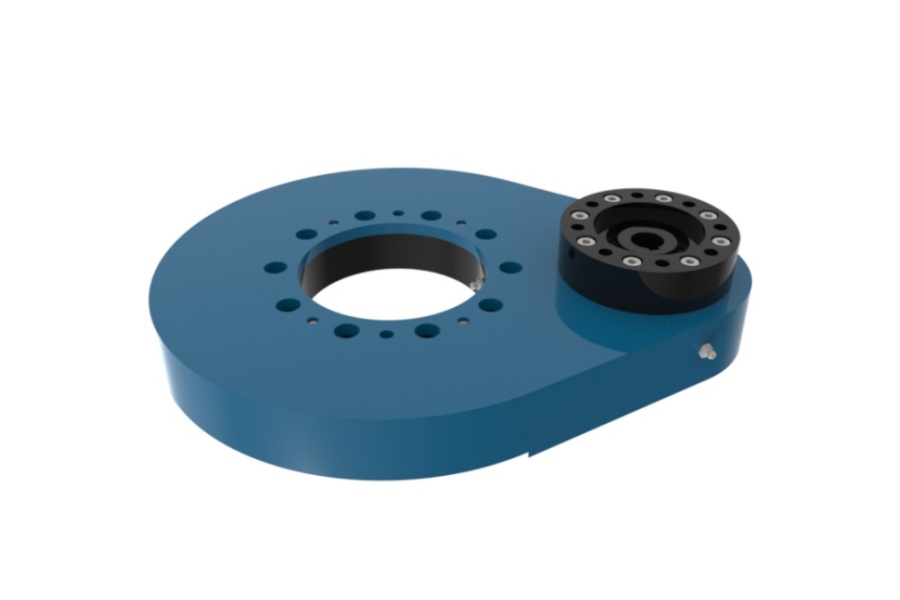

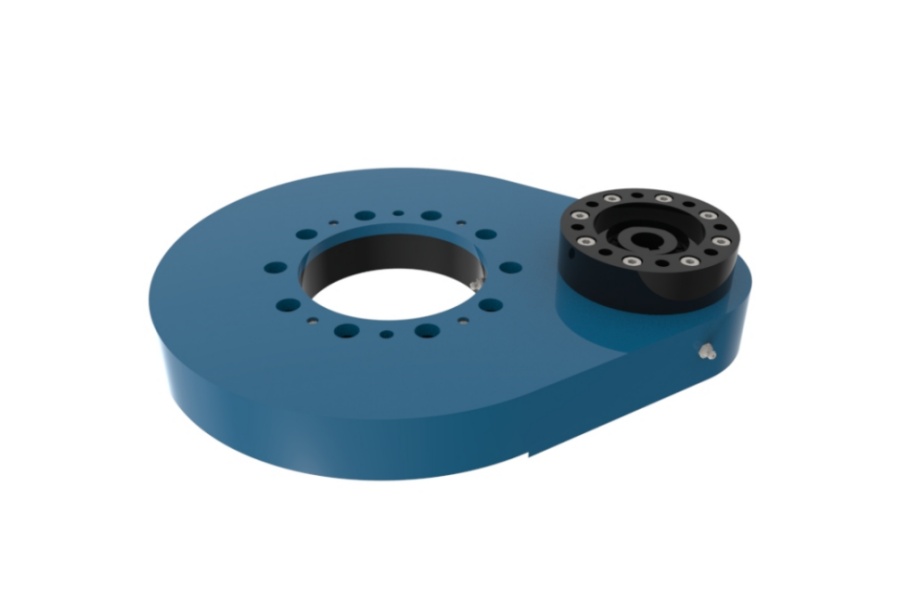

What is Spur Gear Slew Drive

A Spur Gear Slew Drive is a fully integrated rotational actuation system that combines a slewing ring bearing, a spur gear, a housing, a drive mechanism (typically an electric or hydraulic motor), sealing elements, and mounting flanges into a single, compact unit. Its core operational principle relies on the spur gear, which is mounted on the input shaft, directly engaging with and driving the internal gear teeth of the slewing ring's raceway. This direct meshing action converts the input torque from the motor into a powerful, controlled rotational output force. The integrated support bearings within the unit are designed to independently handle substantial axial, radial, and moment loads, allowing the entire structure above it to rotate smoothly and precisely. This design offers a highly efficient and robust solution for applications requiring slow-speed, high-torque rotation under significant load, making it a fundamental component in a vast array of heavy-duty machinery.

Analyzing the Importance of Lubricating Grease for Spur Gear Slew Drives

The importance of selecting and maintaining the correct lubricating grease cannot be overstated for the health and functionality of a spur gear slew drive. Essentially, lubrication is the lifeblood of the system. Within a spur gear slew drive, there are three primary critical points that demand consistent and effective lubrication: the rolling element raceways of the slewing bearing, the meshing teeth of the internal gear and the pinion (spur gear), and the support bearings for the input shaft. Each of these points is subject to different types of mechanical stress and motion. The raceways and support bearings experience rolling contact, while the gear teeth undergo a complex combination of rolling and sliding friction. Inadequate lubrication at any of these points leads to immediate and severe consequences.

The primary function of the grease is to create a persistent protective film that separates these metal surfaces, preventing direct metal-to-metal contact. This separation drastically reduces friction and wear during operation. By minimizing friction, the drive operates more efficiently, requiring less input energy to achieve the desired output, which in turn reduces operational costs and heat generation. Excessive heat is a major enemy of bearings and gears, as it can break down the lubricant, cause thermal expansion of components leading to preload loss or seizure, and accelerate the degradation of seals.

Furthermore, high-quality grease acts as a barrier against corrosion and contamination. Seals are excellent at keeping out large particles, but they are not impervious. Over time, moisture and microscopic abrasive contaminants can ingress. The grease helps to protect internal surfaces from rust and corrosion caused by moisture. It also helps to trap and suspend solid contaminants, preventing them from grinding against finely machined surfaces, thus mitigating abrasive wear.

The consequences of improper lubrication are severe and costly. Insufficient lubrication leads to increased friction, resulting in elevated operating temperatures, accelerated wear, pitting on gear teeth and raceways, and ultimately, catastrophic failure through seizing or tooth shear. The statistical evidence underscores this criticality; studies suggest that approximately 38% of all mechanical failures are directly attributable to lubrication-related issues. Furthermore, it is estimated that a staggering 30% to 50% of global energy loss is due to friction, and about 75% of component failures are rooted in wear. These staggering figures highlight the immense economic and operational impact of friction and wear, making effective lubrication not just a maintenance task but a crucial strategy for sustainability and cost reduction.

For spur gear slew drives, a lithium-complex based grease with extreme pressure (EP) and anti-wear (AW) additives, such as Mobilux EP 2, is highly recommended. The NLGI Grade 2 consistency is ideal as it provides a good balance, being soft enough to flow and replenish contact surfaces while thick enough to stay in place and not leak out. The EP additives are vital for protecting the gear teeth under the high shock loads and pressures inherent in slew drive applications. Therefore, strictly adhering to the manufacturer's installation and maintenance manual for the correct grease type, regreasing intervals, and filling quantities is absolutely paramount to ensuring smooth equipment operation, maximizing service life, and avoiding expensive unplanned downtime and component replacements.

Spur Gear Slew Drive Characteristics

Spur gear slew drives are distinguished by several key characteristics that make them suitable for demanding applications. Their most notable feature is their ability to generate exceptionally high torque output relative to their compact size. This is due to the mechanical advantage provided by the gear reduction within the unit. They are engineered to withstand immense multi-directional load combinations, including axial, radial, and tilt moment loads, all within a single, self-contained package. This simplifies design and installation for engineers, as the drive manages these complex forces internally.

The spur gear design itself offers advantages in simplicity and cost-effectiveness. The straight-cut teeth are easier to manufacture with high precision compared to some other gear types, leading to a robust and potentially more economical solution. They provide high positional accuracy and excellent rigidity, ensuring minimal backlash and torsional deflection when properly specified and maintained. This stability is crucial for applications requiring precise movement and holding under load. Furthermore, their integrated design offers significant space savings, reducing the need for multiple separate components like bearings, gears, and housings, which streamlines the overall machine design. They are also known for their durability and reliability in harsh environments, especially when equipped with appropriate seals and protective coatings.

Spur Gear Slew Drive Applications

The robust and reliable nature of spur gear slew drives makes them indispensable across a wide spectrum of industries. Their ability to provide controlled, powerful rotation under heavy load is utilized in countless applications. In the solar power sector, they are the primary actuation mechanism for accurately positioning and tracking photovoltaic (PV) panels throughout the day to follow the sun's path, maximizing energy capture. Similarly, in the wind energy industry, they are crucial for the yaw and pitch control systems of wind turbines, ensuring the blades are optimally angled to the wind.

The construction and mining industries heavily rely on these drives for equipment such as excavators, cranes, and tunnel boring machines, where they facilitate the rotation of booms, cabins, and digging assemblies. In material handling, they are found in stackers, reclaimers, and ship loaders at ports, and in various types of robotic automation and welding positioners within manufacturing plants. The agricultural sector uses them in large irrigation systems and heavy machinery. Essentially, any application that requires slow, powerful, and dependable rotational movement is a potential use case for a spur gear slew drive.

Factors Influencing Spur Gear Slew Drive Price

The cost of a spur gear slew drive is not a fixed value and is influenced by a multitude of engineering and market factors. Understanding these variables is key to making an informed purchasing decision. Firstly, the physical size and load capacity are primary determinants. A larger drive engineered to handle higher axial, radial, and moment loads will require more material, larger bearings, and more robust gears, significantly increasing its cost. The quality and source of the raw materials, particularly the steel used for the gears and bearing rings, also greatly impact price and performance. High-grade, hardened chromium steel is standard for high-performance drives.

The type and quality of the sealing solution are critical for drives operating in demanding environments. Sophisticated multi-labyrinth seals or other advanced sealing technologies add to the cost but are essential for keeping contaminants out and grease in. The choice and brand of the input drive mechanism, whether it's an electric motor (and its type, e.g., worm gear, planetary gear), a hydraulic motor, or a manual input, represent a significant portion of the total cost. The required precision level, often defined by parameters like backlash and running accuracy, also affects the price. Tighter tolerances require more advanced manufacturing and quality control processes.

Additional factors include any need for customizations, such as special mounting flanges, shaft configurations, coatings (e.g., corrosion protection for marine environments), or paint. The purchase volume (a single unit vs. a large OEM order) influences the unit price due to economies of scale. Finally, the manufacturer's reputation for quality, reliability, and the comprehensiveness of their after-sales support and warranty can command a premium but offers long-term value and peace of mind.

Supplier of Spur Gear Slew Drive

For engineers and procurement specialists seeking a reliable source for high-performance spur gear slew drives, LYRADRIVE stands out as a premier manufacturer and global supplier. The company has established a strong reputation for engineering excellence and producing robust, durable drives that meet the rigorous demands of industries such as renewable energy, construction, and material handling. LYRADRIVE's product range is designed with a focus on precision, high load-bearing capacity, and longevity, ensuring optimal performance in even the most challenging operating conditions. They achieve this through stringent quality control processes, the use of premium materials, and advanced manufacturing techniques. Furthermore, LYRADRIVE emphasizes customer support, offering technical expertise to help select the perfect drive for a specific application and providing reliable after-sales service. Choosing a supplier like LYRADRIVE means investing in a critical component backed by quality, innovation, and dedicated support, ultimately contributing to the enhanced productivity and reliability of your equipment.