High Precision Spur Gear Slew Drive Popularity Reasons

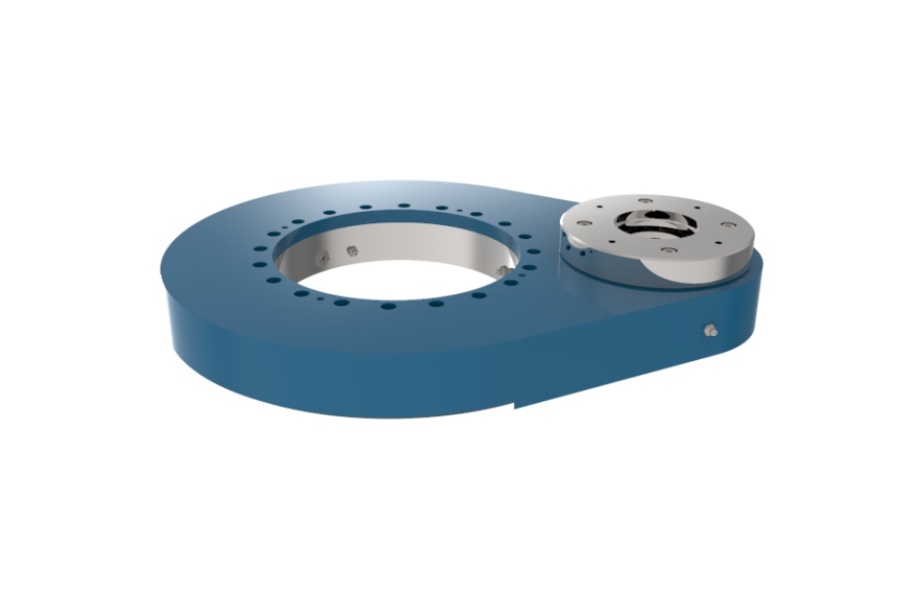

What is Spur Gear Slew Drive

Spur Gear Slew Drive represents an advanced rotational power transmission system that integrates a slewing bearing with precision spur gearing to deliver exceptional rotational accuracy and efficiency. Unlike traditional worm gear systems, this configuration utilizes straight-cut gears mounted parallel to the axis of rotation, providing direct and efficient power transfer with minimal energy loss. The complete assembly incorporates high-precision gears, premium bearings, advanced sealing systems, and precision mounting interfaces into a single compact unit. This integrated design approach eliminates the need for additional gearing components while providing superior load-handling capabilities and positional accuracy. The fundamental operating principle involves the engagement between the pinion gear and the integrated spur gear teeth, converting input rotational power into controlled output movement with exceptional precision and repeatability.

Why High Precision Spur Gear Slew Drives Are So Popular

The remarkable popularity of high-precision spur gear slew drives stems from their unique combination of technical excellence, operational simplicity, and economic efficiency that addresses numerous challenges faced by engineers and equipment designers across various industries.

The exceptional installation simplicity represents one of the most significant factors driving their widespread adoption. The three-step installation process revolutionizes equipment integration by eliminating complex alignment procedures and specialized tools typically required for traditional drive systems. The straightforward mounting procedure begins with securing the drive unit to the base structure using standard fasteners and mounting interfaces. The second step involves attaching the rotating platform or equipment directly to the drive's output flange, utilizing precision-machined mounting surfaces that ensure perfect alignment without additional adjustments. The final step connects the drive motor to the adapter flange, completing the mechanical installation with minimal effort and technical expertise. This simplified approach significantly reduces installation time and costs while eliminating potential errors that could affect long-term performance.

Maintenance efficiency constitutes another crucial factor contributing to their popularity. The extended maintenance intervals, requiring lubrication only every six to twelve months depending on operational intensity, dramatically reduce downtime and maintenance costs. The advanced sealing technology incorporated into these systems provides superior protection against environmental contaminants, including dust, moisture, and chemical exposure that typically accelerate wear in conventional systems. The completely enclosed design maintains lubrication integrity while preventing contaminant ingress, ensuring consistent performance throughout the extended service intervals. This maintenance advantage becomes particularly valuable in applications where accessibility is limited or where maintenance operations would require significant production interruptions.

Operational performance characteristics further enhance their appeal across numerous applications. The spur gear design delivers higher efficiency compared to worm drive alternatives, reducing energy consumption and heat generation during operation. The precision manufacturing of gear teeth ensures minimal backlash and exceptional positional accuracy, enabling precise control of rotational movement even under substantial load conditions. The robust construction and premium materials provide exceptional durability and reliability, supporting continuous operation in demanding industrial environments. The direct power transmission capability allows for higher rotational speeds when required, expanding application possibilities beyond traditional slew drive capabilities.

Economic advantages complete the compelling value proposition that drives their popularity. The reduced maintenance requirements and extended service intervals significantly lower total cost of ownership throughout the equipment lifecycle. The high efficiency operation translates to lower energy consumption, particularly important in high-cycle applications where energy costs represent a substantial operational expense. The reliability and durability minimize unplanned downtime and associated production losses, while the simplified installation reduces initial project costs and commissioning time. These economic benefits, combined with the technical advantages, create a powerful value proposition that justifies the initial investment in high-precision spur gear technology.

Characteristics of Spur Gear Slew Drive

Spur gear slew drives possess distinctive characteristics that make them exceptionally suitable for precision applications across various industries. Their most notable feature is the high efficiency power transmission achieved through the spur gear design, which typically achieves 97-98% efficiency compared to 50-90% efficiency ranges for worm drive systems. The precision engineering enables exceptional positional accuracy, with many systems achieving positioning repeatability within ±1 arc-minute or better through precision ground gears and optimized tooth profiles. The compact integrated design provides significant space savings compared to traditional drive systems, incorporating all necessary components into a single robust housing that simplifies installation and reduces overall system complexity. The maintenance-friendly design features extended lubrication intervals and easily accessible service points that minimize downtime and reduce lifetime maintenance costs. The environmental protection capabilities include advanced sealing systems that typically achieve IP65 or higher protection ratings, ensuring reliable operation in challenging conditions. The versatility of mounting configurations allows for flexible integration into various equipment designs, with multiple mounting options and interface possibilities that accommodate diverse application requirements.

Applications of Spur Gear Slew Drive

The unique combination of precision, efficiency, and reliability enables spur gear slew drives to serve critical functions across numerous industrial sectors and applications. In industrial automation, they are extensively used in robotic workstations, automated assembly lines, and precision indexing tables where high accuracy and repeatability are essential for manufacturing quality. The renewable energy sector employs these drives in solar tracking systems, where their high efficiency and precision enable optimal panel orientation throughout the day, significantly increasing energy capture efficiency. Material handling equipment utilizes spur gear slew drives in rotary conveyors, stackers, and positioners that require precise movement control under variable load conditions. The aerospace and defense industries incorporate these precision drives in radar systems, satellite communication equipment, and weapon platforms where reliability and accuracy are critical for operational success. Medical equipment manufacturers utilize them in advanced imaging systems including CT and MRI scanners, where smooth, precise rotation is essential for diagnostic accuracy. Entertainment industry applications include rotating stages and special effects equipment that require silent operation and precise positioning capabilities. Additional applications include precision machining equipment, scientific instruments, and telescope positioning systems that demand the highest levels of accuracy and reliability.

Factors Influencing the Price of Spur Gear Slew Drive

The cost structure of spur gear slew drives is influenced by numerous technical and commercial factors that reflect their advanced design and performance capabilities. The primary cost driver is the precision manufacturing requirements, with gear quality and accuracy specifications significantly impacting production costs through advanced machining processes and extensive quality control measures. The materials selection represents another major factor, with high-grade alloy steels, specialized coatings, and advanced heat treatment processes adding substantial value while increasing material and processing expenses. Load capacity and physical size requirements influence pricing, with larger units designed for higher loads requiring more material and more complex manufacturing processes that increase production costs. The precision and accuracy specifications significantly affect pricing, with higher accuracy requirements demanding more sophisticated manufacturing equipment and additional quality verification steps that increase production time and costs. Additional features such as integrated brakes, sensors, or special sealing systems designed for specific environmental conditions add functionality but also increase the overall cost through additional components and assembly complexity. Certification requirements including ISO standards, industry-specific qualifications, and third-party verification processes contribute to the total cost through testing and documentation expenses. Finally, order volume, delivery requirements, and customization needs influence pricing through production planning considerations and potential economies of scale that can affect final costs.

Supplier of Spur Gear Slew Drive

LYRADRIVE represents a leading manufacturer and global supplier of high-performance spur gear slew drive solutions, offering comprehensive rotational drive systems that meet rigorous application requirements across various industries. The company maintains an unwavering commitment to quality through advanced manufacturing processes, stringent quality control measures, and continuous product development initiatives. Their product portfolio encompasses both standard and customized solutions designed to address specific load capacity, environmental condition, and integration requirements, supported by extensive technical expertise and engineering consultation services. LYRADRIVE's technical support team provides comprehensive assistance throughout the selection and integration process, helping customers identify optimal solutions that balance performance requirements with economic considerations. By focusing on reliability, performance, and customer satisfaction, LYRADRIVE has established itself as a trusted partner for businesses that depend on precision rotational drive technology, offering competitive solutions that deliver long-term value through superior engineering and manufacturing excellence.