Slewing Bearing Failure Causes and Repair Methods in Construction Machinery

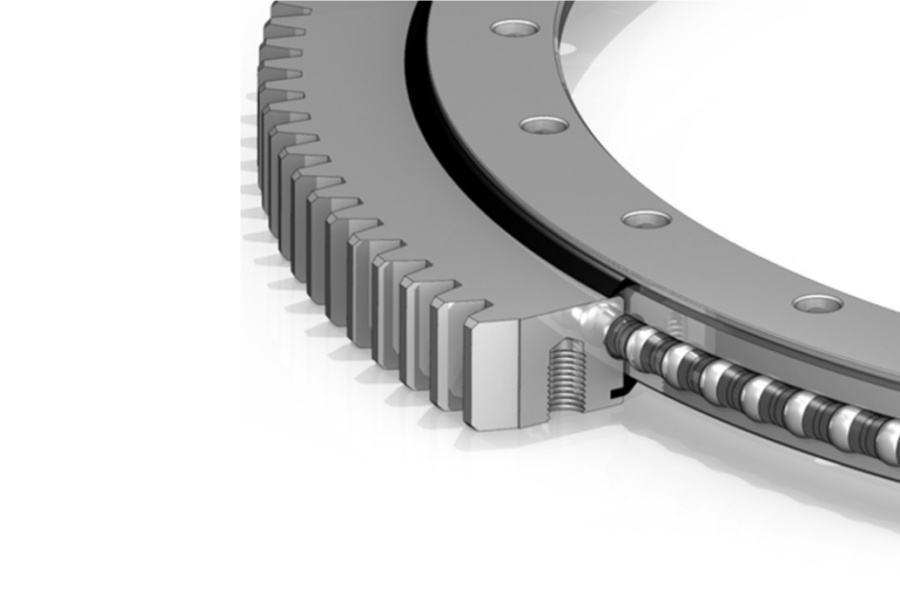

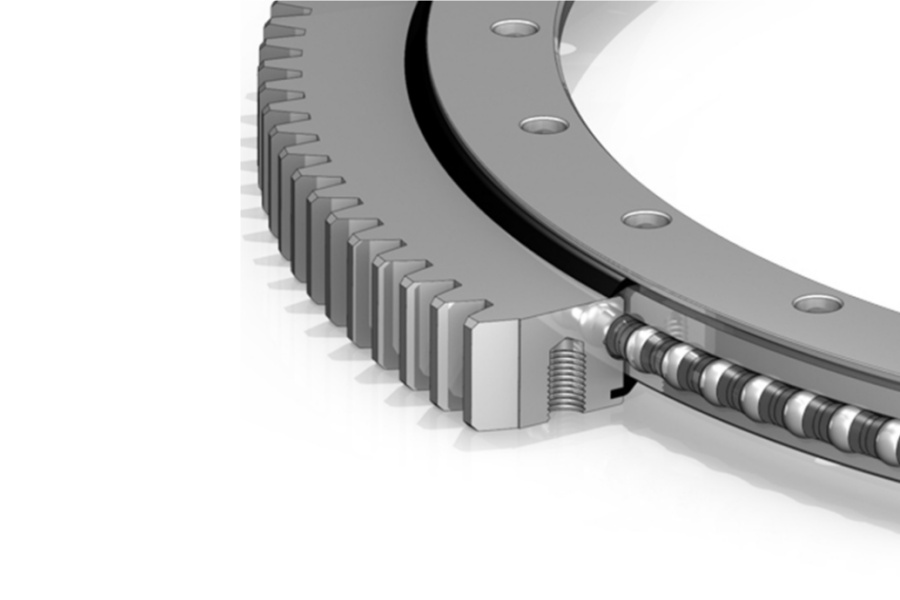

What is Slewing Bearing

Slewing bearing represents a specialized rotational bearing system designed to handle combined loads including axial, radial, and moment loads in various industrial applications. Unlike conventional bearings, slewing bearings feature integrated gear teeth and mounting holes that enable direct connection to structural components and drive systems. These robust components consist of inner and outer rings with raceways containing rolling elements (balls or rollers) that facilitate smooth rotation between connected structures. The unique design incorporates sealing systems to protect internal components from contamination and lubrication systems to ensure optimal performance. Slewing bearings serve as critical interconnection points in heavy equipment where relative rotation between components occurs under significant load conditions, making their proper maintenance and repair essential for equipment safety and performance.

Slewing Bearing Failure Causes and Repair Methods in Construction Machinery

Slewing bearing failures in construction machinery present serious operational challenges that require immediate attention and proper repair methodologies to restore equipment functionality and prevent catastrophic operational failures.

The most prevalent failure mode involves wear and damage to rolling elements and raceways. The steel balls or rollers and their corresponding raceways, formed by precisely machined grooves in the inner and outer rings, undergo constant stress during operation. This wear manifests as surface pitting, spalling, or deformation that compromises the bearing's ability to maintain proper clearances and smooth operation. In construction equipment, this damage typically results from inadequate lubrication, contamination ingress, or excessive operational loads beyond design specifications. The specialized tangential mounting holes used during manufacturing for ball installation become critical points for inspection during maintenance procedures, as improper sealing of these holes can permit contamination entry that accelerates wear progression.

Operational symptoms of advancing slewing bearing failure include increasing rotational resistance, abnormal noises during movement, and detectable clearance development between connected components. As wear progresses, equipment operators may notice requiring higher hydraulic pressure to initiate and maintain rotation, accompanied by grinding or crunching sounds that indicate metal-to-metal contact between damaged surfaces. The most critical assessment method involves measuring vertical play between upper and lower structures using dial indicators mounted on stationary components while applying load variations. Excessive deflection beyond manufacturer specifications confirms advanced wear requiring immediate intervention. During load cycling operations, visual observation often reveals noticeable movement between connected structures that indicates loss of preload and developing clearance in the bearing assembly.

Repair methodologies range from component replacement to complete bearing assembly replacement based on damage severity. For moderate wear conditions where raceways remain structurally sound, upgrading to oversized rolling elements represents a cost-effective repair solution. This process involves meticulous cleaning and inspection of all components, precision measurement of raceway dimensions, and calculation of appropriate oversize ball or roller specifications that restore proper preload and operational clearances. However, when inspection reveals cracking, severe spalling, or excessive raceway deformation, complete bearing replacement becomes necessary to ensure operational safety and performance. During repair procedures, special attention must be given to bolt connection integrity, as improper tightening of mounting hardware represents a common cause of premature failure and requires strict adherence to manufacturer specified torque sequences and values.

Preventive maintenance practices significantly extend slewing bearing service life through regular lubrication and inspection protocols. Proper lubrication intervals using manufacturer-recommended grease types and quantities maintain protective films between contact surfaces while purging contaminants through designated relief channels. Regular visual inspections should examine seal integrity, lubricant condition, and evidence of abnormal wear patterns that might indicate developing problems. Operational monitoring through vibration analysis and temperature checks provides early warning of lubrication breakdown or component deterioration before catastrophic failure occurs. Environmental protection measures including protective covers and proper storage practices further enhance component longevity in demanding construction applications.

Characteristics of Slewing Bearing

Slewing bearings possess distinctive characteristics that make them indispensable for heavy equipment applications while presenting unique maintenance considerations. Their most significant feature is the ability to handle combined load types simultaneously, including axial forces, radial loads, and moment loads through optimized structural design and material selection. The integrated gear teeth represent another critical characteristic, providing direct drive interface capabilities that eliminate additional transmission components and simplify system architecture. Customization capabilities allow for specific mounting configurations, sealing arrangements, and material selections tailored to particular application requirements and environmental conditions. High precision manufacturing ensures exacting dimensional accuracy and surface finish quality that maintain performance under extreme operational conditions. Robust sealing systems protect internal components from environmental contaminants while retaining lubrication essential for prolonged service life. The modular design approach facilitates relatively straightforward replacement procedures despite the critical nature of these components in overall equipment functionality.

Applications of Slewing Bearing

Slewing bearings serve fundamental roles across numerous industrial sectors where controlled rotation under load represents essential functionality. Construction machinery applications represent the most significant market segment, with excavators, cranes, and concrete pumps utilizing large-diameter bearings for superstructure rotation and precise positioning capabilities. Material handling equipment including stackers, reclaimers, and port cranes employ slewing bearings in rotating platforms and lifting mechanisms that require smooth operation under variable loads. Wind energy applications utilize specially designed bearings for yaw and pitch control systems that optimize turbine orientation relative to wind conditions. Military and aerospace implementations include radar systems, weapon platforms, and satellite tracking equipment requiring precise movement and positioning accuracy. Industrial machinery applications encompass robotic workstations, indexing tables, and mixing equipment where controlled rotation enhances manufacturing processes. Renewable energy systems beyond wind power include solar tracking installations that use slewing bearings to precisely orient panels throughout daily movement cycles. Transportation equipment such as heavy haulers and special vehicles incorporate slewing bearings in rotating cabins and material handling components that require reliable performance in demanding operating conditions.

Factors Influencing the Price of Slewing Bearing

The cost structure of slewing bearings reflects numerous technical and commercial considerations that vary significantly based on application requirements and performance specifications. The primary cost driver remains physical size and load capacity, with larger diameters and higher load ratings requiring substantially more material and advanced manufacturing processes that increase production costs. Material selection significantly impacts pricing, with specialized steel alloys, surface treatments, and corrosion protection measures adding substantial value while enhancing performance characteristics. Manufacturing precision requirements influence cost through necessary equipment capabilities, quality control processes, and production time investments that ensure dimensional accuracy and performance reliability. Gear tooth specifications including machining accuracy, heat treatment requirements, and quality verification processes contribute to overall cost based on complexity and precision requirements. Sealing system design and materials affect pricing through component costs and assembly complexity involved in creating effective environmental protection. Certification requirements including ISO standards, industry-specific qualifications, and third-party verification processes add expenses related to testing and documentation compliance. Additional factors include order quantity considerations, delivery requirements, and after-sales support expectations that influence final pricing through operational and commercial considerations beyond pure manufacturing costs.

Supplier of Slewing bearing

LYRADRIVE represents a leading manufacturer and global supplier of high-performance slewing bearing solutions, offering comprehensive rotational components that meet rigorous application requirements across various industries. The company maintains an unwavering commitment to quality through advanced manufacturing processes, stringent quality control measures, and continuous product development initiatives. Their product portfolio encompasses both standard and customized solutions designed to address specific load capacity, environmental condition, and integration requirements, supported by extensive technical expertise and engineering consultation services. LYRADRIVE's technical support team provides comprehensive assistance throughout component selection, installation, and maintenance processes, helping customers optimize equipment performance and reliability through proper bearing application and care. By focusing on reliability, performance, and customer satisfaction, LYRADRIVE has established itself as a trusted partner for businesses that depend on precision rotational components, offering competitive solutions that deliver long-term value through superior engineering and manufacturing excellence.