Slew Drive Usage Precautions

What is Slew Drive

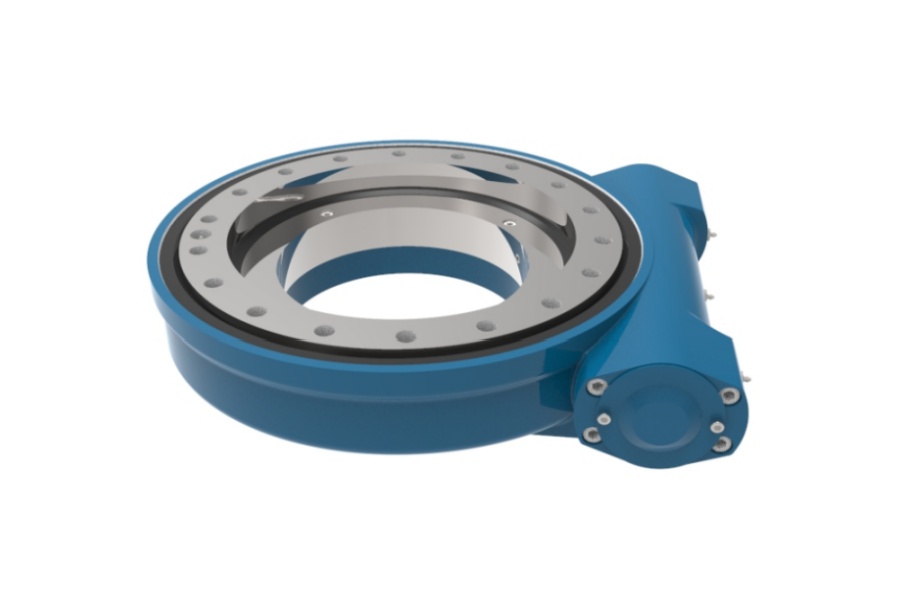

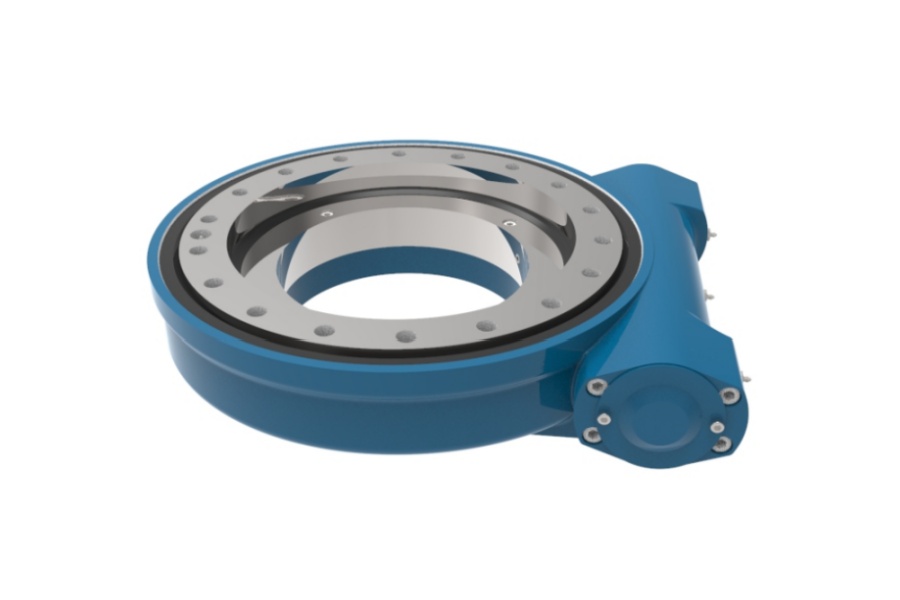

Slew Drive represents an integrated mechanical system that combines a slewing bearing with a worm gear or other drive mechanism to facilitate controlled rotational movement under significant load conditions. This complete assembly incorporates all necessary components including gears, bearings, seals, and mounting interfaces into a single compact unit, providing exceptional structural integrity and operational efficiency. The fundamental purpose of a slew drive is to convert input power from various sources into precise output rotation while simultaneously supporting substantial axial, radial, and moment loads. This integrated approach to rotational power transmission has become essential across numerous industries where space constraints, precision requirements, and reliability are paramount concerns. Proper understanding of operational requirements and maintenance practices forms the foundation for achieving designed performance characteristics and operational lifespan.

Slew Drive Usage Precautions

The proper operation and maintenance of slew drives require careful attention to numerous technical considerations throughout the equipment lifecycle, from initial installation to daily operation and long-term maintenance practices.

Installation procedures demand particular attention to preserving factory settings and configurations. Since slew drives typically arrive as pre-assembled components with critical internal adjustments already completed, installation teams must exercise extreme care to maintain these factory settings during integration with host equipment. For closed-structure designs where the housing and internal transmission components share connection points, the factory pre-connection must remain undisturbed as it involves precise adjustment of transmission clearance and positional alignment. Installation should exclusively utilize the manufacturer-reserved mounting holes specifically designed for host equipment integration rather than attempting to use the pre-connected holes that maintain internal alignment. Any disruption to the original assembly configuration can significantly impact transmission efficiency and operational performance, potentially leading to premature failure or reduced service life.

Lubrication management represents another critical consideration for proper slew drive operation. While manufacturers pre-fill units with appropriate lubricants before shipment, end-users must establish and maintain regular lubrication schedules according to operational requirements and environmental conditions. The lubrication system requires periodic inspection to ensure proper lubricant levels and quality, with particular attention to seal integrity that prevents contaminant ingress and lubricant leakage. Proper lubrication intervals must account for operational intensity, environmental factors, and manufacturer recommendations, using specified lubricant types and quantities to maintain optimal performance. Documentation should include lubrication history tracking that records dates, lubricant types, quantities, and observations made during maintenance procedures to establish proper maintenance patterns and identify developing issues.

Operational practices significantly influence slew drive longevity and reliability. Despite their high integration, structural simplicity, and performance advantages, these systems require careful operation to avoid excessive stress and premature wear. Most industrial applications, particularly in construction machinery, require avoidance of high-frequency reciprocating operation under significant impact conditions. The sudden shock loads generated during rapid direction changes or impact events dramatically accelerate wear at gear meshing points, leading to premature failure and reduced operational reliability. Operators should implement smooth acceleration and deceleration protocols, particularly during start-stop transitions, to minimize stress concentrations and impact forces on transmission components.

Maintenance protocols must include regular inspection and preventive measures to ensure continuous reliable operation. Visual inspections should examine seal condition, lubricant quality, and evidence of abnormal wear or damage that might indicate developing problems. Operational monitoring should include regular checks for unusual noises, increased operating temperatures, or changes in rotational resistance that might signal lubrication breakdown or component deterioration. For applications involving low-speed, heavy-load, long-cycle operation, strictly follow design requirements regarding regular lubricant replacement and replenishment schedules. Immediately address any abnormal situations including foreign object ingress, jamming, or operational resistance to prevent secondary damage to transmission components.

Environmental protection measures contribute significantly to prolonged service life. Implement appropriate protective covers and environmental barriers when operating in conditions involving dust, moisture, or chemical exposure. Establish proper storage procedures for equipment during downtime periods, including regular rotation and protective measures against environmental degradation. For applications involving extreme temperature variations, consider appropriate lubricant specifications and operational procedures that account for thermal expansion effects and viscosity changes.

Characteristics of Slew Drive

Slew drives possess distinctive characteristics that make them indispensable for heavy-duty rotational applications while presenting unique operational considerations. Their most significant feature is their integrated design philosophy, which combines multiple functional components into a single compact unit, providing substantial space savings and structural simplicity compared to traditional separate systems. These drives deliver exceptional load-handling capability, simultaneously managing complex load combinations including axial forces, radial loads, and moment loads through robust construction and precision-engineered components. The precision positioning capability represents another critical characteristic, with many systems achieving positioning accuracy within arc-minute ranges through precision gearing and minimal backlash design. Durability is enhanced through the use of high-strength alloy steels, advanced heat treatment processes, and comprehensive sealing systems that ensure reliable performance in demanding industrial environments. The modular design approach facilitates easier installation and maintenance, with standardized mounting interfaces and accessible service points that simplify integration and upkeep while reducing total cost of ownership.

Applications of Slew Drive

The unique combination of strength, precision, and compactness enables slew drives to serve critical functions across numerous industrial sectors and applications. In renewable energy applications, they form the core component of solar tracking systems, precisely orienting photovoltaic panels to maximize energy capture throughout the day, while also serving in wind turbines for pitch and yaw control mechanisms that optimize performance and protect against extreme weather conditions. Construction equipment extensively utilizes slew drives in excavators, cranes, and aerial work platforms, where they provide the rotational capability for booms, platforms, and lifting mechanisms that require smooth operation under variable loads. Material handling equipment incorporates these drives in rotary conveyors, stackers, and manipulators that require controlled rotation with precise positioning capabilities. Industrial automation systems employ slew drives in robotic welding cells, indexing tables, and automated assembly lines where accurate rotational positioning is essential for manufacturing precision. The aerospace and defense sectors utilize them in radar systems, satellite communication antennas, and weapon platforms that require accurate positioning and stability under demanding operational conditions. Even medical equipment manufacturers incorporate precision slew drives in advanced imaging systems like CT and MRI scanners where smooth, reliable rotation is critical for diagnostic accuracy. Additional applications include mining equipment, marine deck machinery, agricultural implements, and telescope positioning systems, demonstrating the remarkable versatility of these components across virtually every sector requiring controlled rotational movement under load.

Factors Influencing the Price of Slew Drive

The cost structure of slew drives is determined by numerous technical and commercial factors that reflect their engineering complexity and performance capabilities. The primary cost driver is the physical size and load capacity rating, with larger units designed for higher loads commanding significantly higher prices due to increased material requirements, more complex manufacturing processes, and enhanced quality control measures. The selection of materials represents another significant factor, with high-grade alloy steels, specialized coatings, and advanced heat treatment processes adding substantial value while increasing manufacturing expenses related to material procurement and processing. Manufacturing precision constitutes a major cost component, as precision-ground gear teeth, honed bearing surfaces, and exacting tolerance control require advanced machinery, skilled labor, and extensive quality verification procedures, all contributing to higher production costs. The type and complexity of the drive mechanism influence price, with gear-type systems generally commanding premium pricing compared to worm drives due to their higher efficiency and speed capabilities, while planetary or hybrid systems offering special features further increase costs. Additional features such as integrated motors, brakes, sensors, or special sealing systems designed for extreme environments add functionality but also increase the overall cost through additional components and assembly complexity. Certification requirements including ISO standards, industry-specific qualifications, and third-party verification processes contribute to the total cost through testing and documentation expenses. Finally, brand reputation, warranty coverage, after-sales support services, and order volume considerations contribute to the total cost of ownership, with established manufacturers typically commanding premium prices based on proven reliability and comprehensive technical support offerings.

Supplier of Slew Drive

LYRADRIVE represents a leading manufacturer and global supplier of high-performance slew drive solutions, offering comprehensive rotational drive systems that meet rigorous application requirements across various industries. The company maintains an unwavering commitment to quality through advanced manufacturing processes, stringent quality control measures, and continuous product development initiatives. Their product portfolio encompasses both standard and customized solutions designed to address specific load capacity, environmental condition, and integration requirements, supported by extensive technical expertise and engineering consultation services. LYRADRIVE's technical support team provides comprehensive assistance regarding proper installation procedures, operational practices, and maintenance protocols, helping customers maximize equipment lifespan and performance through optimized usage practices. By focusing on reliability, performance, and customer satisfaction, LYRADRIVE has established itself as a trusted partner for businesses that depend on precision rotational drive technology, offering competitive solutions that deliver long-term value through superior engineering and manufacturing excellence.