Slewing Bearing Assembly Process

What is a Light Load Slewing Bearing

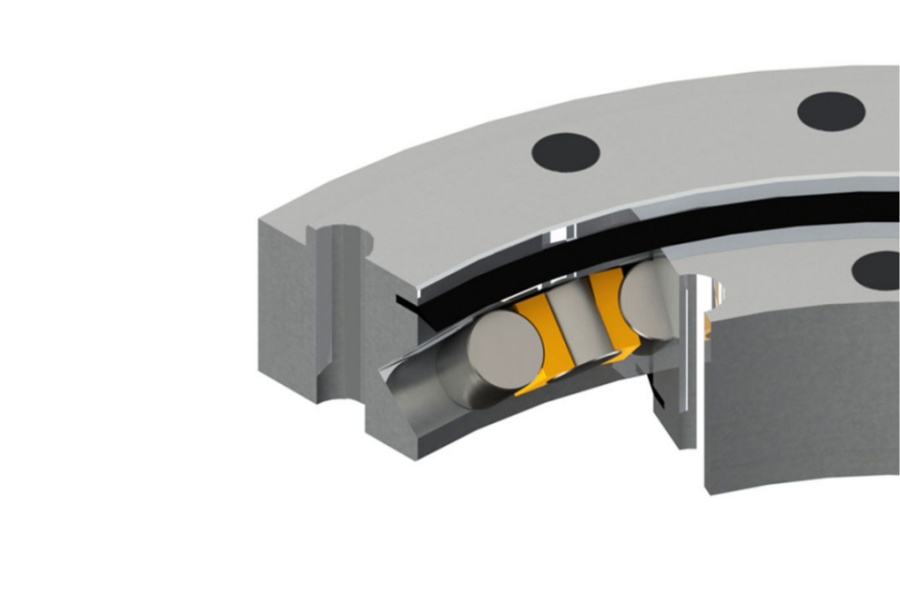

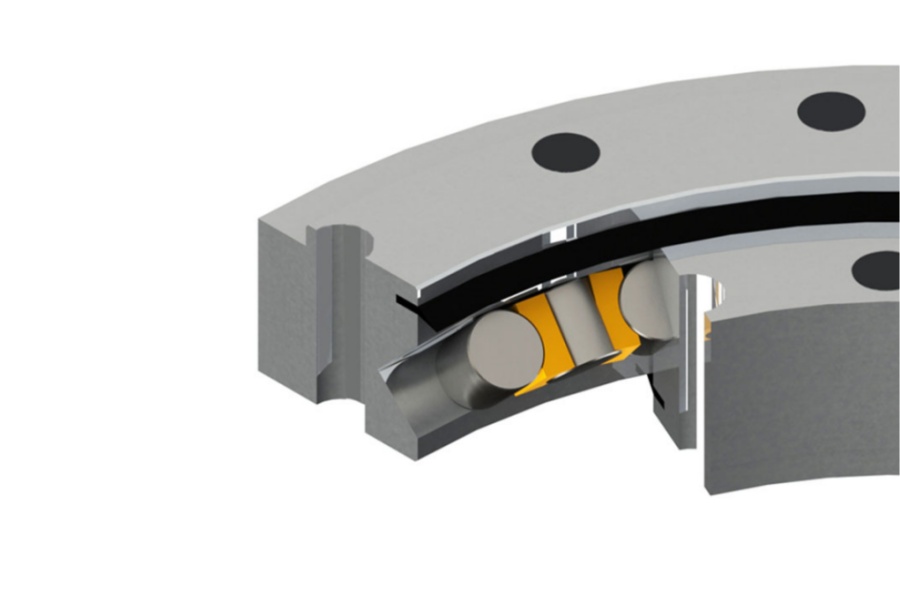

Light Load Slewing Bearing is a compact, precision rotational bearing engineered to facilitate smooth and controlled movement between structures under moderate axial, radial, and moment loads. Characterized by a lower cross-section and often a single-row design, it provides an optimal balance of performance, space efficiency, and cost-effectiveness for applications where extreme force is not a primary concern. A Light Load Slewing Bearing typically consists of an inner ring and an outer ring (one or both may incorporate gear teeth), a single row of high-precision rolling elements (balls or rollers), a cage or segregation blocks to maintain element spacing, contact or non-contact seals for protection, and lubrication fittings. Despite its "light load" designation, the integrity of its assembly process is just as critical as that of its larger counterparts, as improper assembly remains a leading cause of premature noise, wear, and failure, undermining the component's designed lifespan and performance.

Slewing Bearing Assembly Process

The assembly of a slewing bearing is a precise and methodical operation that demands a clean environment, meticulous attention to detail, and strict adherence to established procedures. It is far more than simply putting parts together; it is a quality-focused process that directly determines the bearing's operational characteristics, including smoothness, rotational torque, noise level, and ultimate service life. The following steps outline the standard industry practice for a proper and thorough assembly process.

Component Inspection and Preparation

The process begins with a rigorous inspection of all incoming components. Each ring, rolling element, seal, and isolation block is carefully examined for any visual defects such as shipping damage, deep nicks, rust spots, or scratches. Critical dimensions are verified against engineering drawings to ensure all parts are within specified tolerances before assembly commences, preventing costly rework later. A crucial step is identifying the bearing's "soft zone"—an unhardened section of the ring left for heat treatment purposes—which is permanently marked by the manufacturer, typically with a stamped 'S' and a plastic plug in an adjacent bolt hole. The rings are matched according to their grinding batch numbers to ensure perfect compatibility and optimal performance.

Surface Treatment and Deburring

Any minor surface imperfections must be addressed. Light rust on non-critical surfaces is carefully removed using a non-abrasive scouring pad and a suitable cleaning solvent. More significant rust or raised burrs, particularly around bolt holes, lubrication ports, seal grooves, and chamfers, are meticulously ground down using a handheld grinder equipped with a soft abrasive disc. This step is vital to prevent the creation of stress concentrators, ensure a perfect seal fit, and guarantee that bolts torque down correctly onto smooth, flat surfaces. The goal is to create perfectly smooth, deburred edges everywhere.

Thorough Cleaning

After deburring, the component must be immaculately cleaned. Compressed air is used first to blow out any microscopic metallic particles or abrasive dust leftover from machining and grinding processes from the bolt holes, gear teeth, and raceways. Following this, the parts are washed with a industrial-grade solvent such as kerosene or diesel to remove all traces of oil, grease, and any remaining microscopic contaminants. This ensures that no abrasive particles are left inside the bearing to cause premature wear once it is sealed and put into operation. The cleaned components are then moved to a dedicated, clean assembly area to prevent re-contamination.

Rolling Element Installation

This is the core of the mechanical assembly. The ring containing the pre-drilled plug holes is positioned securely, often supported on wooden blocks to protect its finished surfaces. The matching ring is then carefully lowered into place, aligning their raceways perfectly. The installer begins by manually placing several rolling elements (balls or rollers) spaced evenly around the circumference to support the upper ring. With the rings supported and aligned, the remaining rolling elements and their corresponding isolation blocks are inserted through the main plug port. The installer slowly rotates the upper ring, feeding in the elements and blocks until the raceway is full. The specific arrangement and quantity of blocks are dictated by the design drawings. The final gap is measured precisely, and a specially selected thicker or thinner isolation block is used to achieve the correct fit, ensuring the gap is never larger than the length of one block to prevent them from tilting and causing a jam during operation.

Plug Installation and Final Sealing

Once the raceway is correctly packed, the main access port is sealed. The hardened steel plug is carefully driven into its bore. A critical subsequent step is the installation of a tapered pin through a cross-hole in the plug and the ring itself. This pin mechanically locks the plug in place, guaranteeing it cannot ever work loose during operation, which would be catastrophic. The pin is installed from the smaller-diameter end and must be seated so both ends are flush with or below the surrounding surfaces. After the pin is secured, the surrounding area is often lightly staked or peened to further secure the assembly.

Comprehensive Quality Testing

With the bearing fully assembled, it undergoes a battery of rigorous quality control checks. It is first rotated manually by experienced technicians to subjectively assess smoothness, feel for any binding, and listen for abnormal noises. Objective measurements are then taken using precision dial indicators and specialized tools. These tests include measuring axial and radial internal clearance, checking gear tooth runout (if applicable), verifying total height and face flatness, measuring raceway runout, and confirming the rotational starting torque meets specifications. This comprehensive testing validates that the assembly was performed correctly and that the bearing left the factory in perfect condition.

Lubrication, Sealing, and Marking

After passing all inspections, the final grease fittings (zerk fittings) are installed. The bearing is then filled with the precise type and quantity of grease specified by the customer or the application requirements, ensuring all internal surfaces are coated for protection and initial operation. The seals—critical for keeping contaminants out and grease in—are then carefully pressed into their grooves. For split seals, the ends are glued together with a high-strength adhesive to form a continuous ring. Finally, essential identification information, such as the part number, serial number, and date code, is permanently stamped onto a designated surface of the bearing.

Preservation and Packaging

The completely assembled, tested, and marked bearing is prepared for shipping. Its exposed steel surfaces are coated with a high-quality, rust-preventative oil or grease to protect it from corrosion during transit and storage. It is then wrapped in a multi-layer packaging system: first a layer of oil-resistant barrier film, followed by a layer of protective paper, and finally an outer layer of heavy-duty plastic stretch film or a custom wooden crate for maximum protection against physical damage and environmental elements. A product label containing all relevant shipping and product data is affixed to the outside of the package before it is moved to the warehouse.

Characteristics of Light Load Slewing Bearing

Light Load Slewing Bearings are defined by a specific set of characteristics that make them ideal for their intended applications. Their most notable feature is their compact and lightweight design, featuring a low cross-sectional height which allows for integration into space-constrained machinery without compromising performance. They are primarily configured with a single row of balls, which provides an excellent balance of load capacity and low friction for smooth, efficient rotation. The materials used are often optimized for cost-effectiveness and performance under moderate loads, potentially utilizing different steel grades or heat treatment processes than heavy-duty bearings. Their integrated sealing systems are typically simpler, often consisting of single-lip non-contact or lightly contacting seals, designed to retain grease and exclude larger contaminants without introducing significant drag torque. Despite their lighter duty classification, they still maintain the core functionalities of standard slewing bearings, including mounting holes for easy installation and often offering optional integrated gear teeth for drive capabilities. Their design prioritizes economical efficiency, precise motion, and quiet operation under manageable load conditions.

Applications of Light Load Slewing Bearing

The versatility and compact form factor of Light Load Slewing Bearings make them suitable for a vast array of applications across numerous industries where heavy loads are not a primary factor. A common application is in light-duty material handling equipment, such as small robotic arms used in assembly lines, pick-and-place units, and rotary tables on indexing equipment. The agricultural sector utilizes them in smaller machinery attachments, like seeders, sprayers, or the rotating platforms on certain types of trailers. They are found in a multitude of industrial machinery, including light-duty welding positioners, packaging equipment, and rotary feeders. In the realm of renewable energy, they can be used in solar tracking systems to precisely orient panels toward the sun throughout the day. Furthermore, they are present in various medical equipment for precise rotational positioning, in recreational vehicles for antenna or sensor platforms, and in countless other machines that require reliable, controlled rotation without the extreme forces seen in mining or heavy construction.

What Factors Influence the Price of Light Load Slewing Bearing

The cost of a Light Load Slewing Bearing is influenced by several interconnected factors that reflect its design, manufacturing complexity, and material composition. The physical size and dimensions, particularly the outer diameter and cross-sectional height, are primary drivers, as they determine the amount of raw material required. The inclusion of optional features, most notably precision-machined gear teeth (internal or external), adds significant machining time and cost. The material specification is another key factor; standard carbon steel might be used for very light duties, while higher-grade alloy steels or specific coatings will increase the price. The required precision tolerance grade also impacts cost; bearings manufactured to tighter tolerances for applications requiring minimal runout and smooth operation demand more advanced machining and quality control. The type and quality of accessories, such as seals (standard rubber vs. advanced polyurethane) and the inclusion of pre-drilled lubrication fittings, add to the overall cost. Finally, order volume plays a significant role; a large production run allows for economies of scale, significantly reducing the unit cost compared to a small custom order for a prototype or specialized machine.

Supplier of Light Load Slewing Bearings

For designers and engineers seeking reliable and precision-engineered rotational solutions for light to medium-duty applications, LYRADRIVE presents itself as a capable and experienced supplier. The company specializes in the design and manufacturing of a wide range of slewing products, including high-performance Light Load Slewing Bearings that meet rigorous quality standards. LYRADRIVE's focus on engineering excellence ensures that even their compact bearings offer optimal performance, durability, and smooth operation. They provide valuable technical support to assist with selection, integration, and maintenance, ensuring customers achieve the maximum possible service life from their components. By choosing LYRADRIVE, customers partner with a supplier dedicated to delivering quality and reliability, contributing directly to the enhanced performance and longevity of their end products.