Common Types of Slewing Bearings

What is a Slewing Bearing

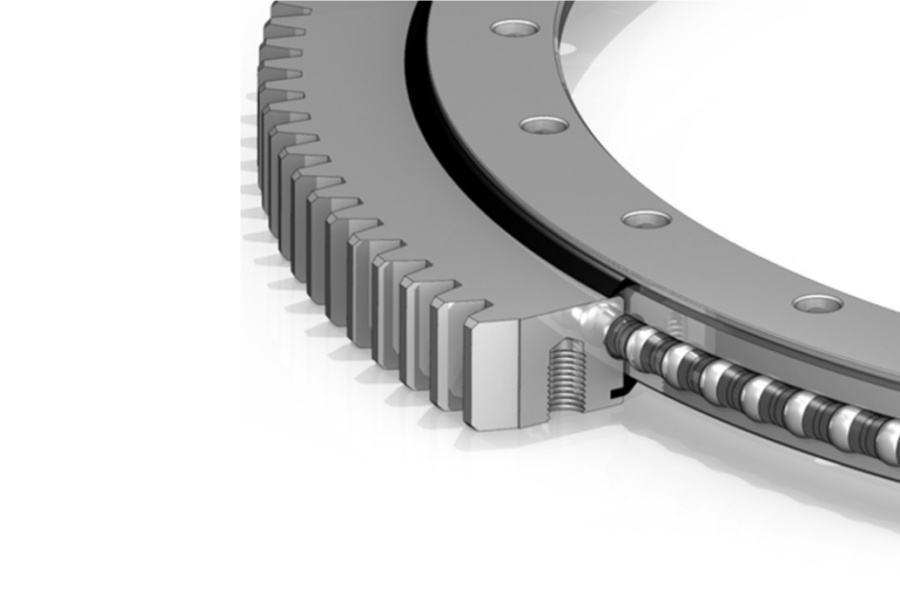

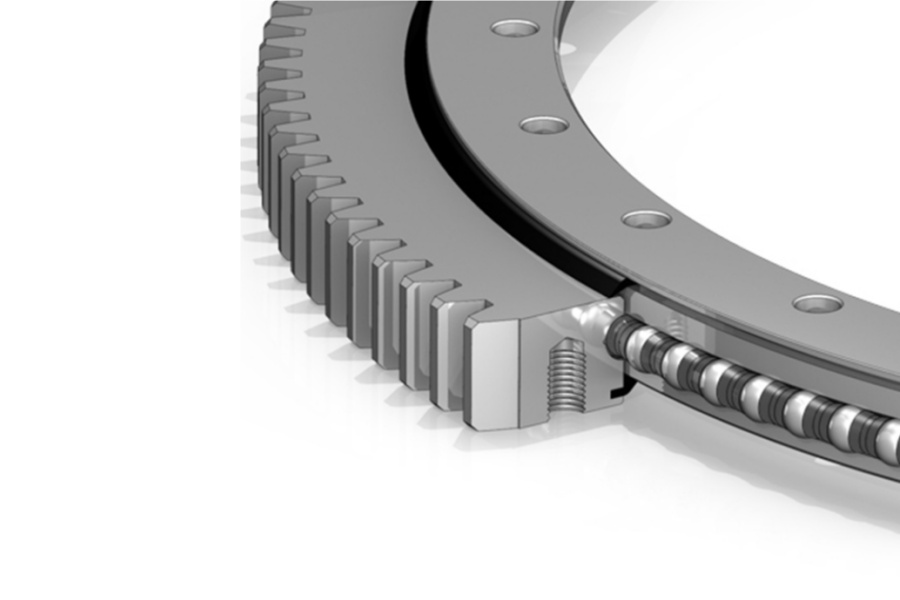

Slewing Bearing is a critical rotational mechanical component engineered to facilitate relative movement between two structures while simultaneously supporting complex combinations of extreme loads. It functions as a robust, integrated connection point, typically comprising an outer ring (which may be gearless or feature internal/external gear teeth), an inner ring (also potentially geared), rolling elements (high-grade steel balls or cylindrical rollers), segregation blocks or a cage to maintain precise spacing between these elements, high-performance seals to protect against contaminant ingress and retain lubrication, and lubrication fittings for systematic maintenance. This sophisticated design allows it to uniquely handle substantial axial forces, radial forces, and tilting moments within a single, compact unit, a capability that would otherwise require a complex system of multiple standard bearings. Its role is fundamental across countless industries where controlled rotation under load is paramount.

Common Types of Slewing Bearings

The diversity in machinery design and operational demands has led to the development of several specialized slewing bearing types, each optimized for specific load conditions, precision requirements, and spatial constraints. The four most common and fundamental types are the single-row four-point contact ball, the single-row cross roller, the double-row different-diameter ball, and the triple-row roller slewing bearing.

The Single-Row Four-Point Contact Ball Slewing Bearing is renowned for its compact design and versatility. In this configuration, the hardened raceways are designed so that each ball makes contact at four distinct points, typically at a 45-degree contact angle, though other angles like 35° or 55° are used for specific load optimizations. This ingenious design allows a single row of balls to efficiently support combined axial, radial, and moment loads, making it an exceptionally space-efficient solution. The double-row version of this design essentially stacks two rows of balls, significantly increasing its load capacity in all directions while maintaining a relatively low cross-section. This type is a popular general-purpose choice for a vast array of applications where a balance of capacity, size, and cost is required.

For applications demanding superior rigidity, higher precision, and greater load capacity in a comparably compact package, the Single-Row Cross Roller Slewing Bearing is the preferred choice. Its design is distinctly different, utilizing cylindrical rollers as the rolling elements. These rollers are arranged in a precise 1:1 alternating pattern at 90 degrees to each other between a single inner and outer ring. This cross-oriented arrangement provides a much larger effective contact area with the raceways compared to balls, resulting in significantly higher rigidity, minimal elastic deformation under load, and exceptional rotational accuracy. Due to these superior performance characteristics and a more complex manufacturing process, this type is frequently specified for high-precision equipment such as industrial robots, rotary tables, crane booms, and sophisticated military hardware.

The Double-Row Different-Diameter Ball Slewing Bearings are engineered for applications where axial loads and overturning moments are the primary concerns, such as in large lifting equipment. This design often features a unique split structure, commonly with two inner rings or two outer rings that are bolted together during final assembly, which greatly simplifies the installation process. It incorporates two independent rows of balls. A key feature is that the balls in each row can be of different diameters, allowing engineers to optimize the size of the rolling elements based on the specific load distribution each row will encounter. The raceways are typically designed with a 90-degree contact angle, ideal for supporting massive axial forces and countering heavy overturning moments. This makes it the standard bearing for tower cranes, shipboard cranes, and other machinery where stability against tipping is critical.

At the pinnacle of load-bearing capacity stands the Triple-Row Roller Slewing Bearing, designed for the most extreme and demanding applications in heavy industry. This is the most robust and durable type, characterized by its three separate rows of rollers. Each row has a dedicated function: two rows are dedicated to handling axial loads in opposite directions, and a separate third row is solely responsible for managing all radial loads. This clear separation of load paths is a key advantage, as it allows for the precise engineering of each roller row—each can be sized with different roller diameters and lengths to perfectly match its specific load mandate. By dedicating a row purely to radial loads, the axial load rows can be optimized without compromise. This results in an unparalleled overall load capacity, making it the indispensable choice for the most heavy-duty machinery on the planet, including massive container port cranes, ladle turrets in steel mills, and tunnel boring machines.

Characteristics of Slewing Bearing

Slewing bearings are defined by a set of core characteristics that make them unique and indispensable. Their most critical feature is the ability to handle multi-directional combination loads—axial, radial, and moment loads—simultaneously within a single, integrated unit. They are not just bearings but structural components, often featuring integrated gear teeth for direct drive transmission and numerous mounting holes for direct bolting, which simplifies overall machine design and assembly. Manufactured from high-quality, through-hardened alloy steels, they possess a tough core and a hard, wear-resistant raceway surface to endure immense contact pressures and fatigue. Scalability is another key trait, with sizes produced from just a few centimeters to well over several meters in diameter. Sophisticated multi-lip sealing systems are integral for protection in harsh environments, and built-in lubrication channels ensure all critical contact surfaces are serviced. The variety of internal designs allows for precise performance optimization.

Applications of Slewing Bearing

The application of slewing bearings is virtually universal across heavy industry. In construction, they are the fundamental component in excavators, mobile cranes, tower cranes, and concrete pumps, enabling full rotation. The wind energy sector depends on massive, customized bearings for yaw and pitch systems to optimize turbine alignment with the wind. Material handling equipment like stacker reclaimers in ports and mining operations, as well as heavy-duty robotic welding turntables, rely on their robust performance. The mining industry uses them in draglines and shovels, while they are also critical in defense (tank turrets, radar platforms), aerospace (launch vehicles), medical imaging (CT scanners), and renewable energy (solar trackers).

What Factors Influence the Price of Slewing Bearing

The price of a slewing bearing is determined by a confluence of engineering and manufacturing factors. The most fundamental cost driver is its physical size and dimensions (diameter, height, width), which directly dictate raw material consumption. The required load capacity is equally critical; higher ratings for axial, radial, and moment loads necessitate a more robust design, larger or additional rolling elements, and often higher-grade materials, all increasing cost. The material specification itself (e.g., standard 50Mn vs. high-grade 42CrMo4) and the required heat treatment processes add significant variable cost. Manufacturing complexity is a major factor; integrated gear teeth (especially hardened and ground), custom seal types, special mounting hole patterns, and non-standard lubrication fittings all add machining time and expense. The required precision grade and tolerance level also impact cost, as bearings for high-precision applications demand more advanced manufacturing and quality control. Finally, purchase volume plays a significant role; a large production order benefits from economies of scale, drastically reducing the unit cost compared to a one-off custom design.

Supplier of Slewing Bearing

For those seeking reliable and high-performance slewing solutions, LYRADRIVE stands as a proficient manufacturer and global supplier of a comprehensive range of slewing bearings and drives. The company specializes in the engineering and production of precision rotational products designed for durability, maximum load capacity, and long service life in the most demanding industrial environments. LYRADRIVE's products are characterized by robust engineering, stringent quality control throughout the manufacturing process, and the use of superior materials to ensure consistent performance and reliability. They offer essential technical support, guiding customers from the initial design and selection phase through to installation and maintenance, ensuring optimal system integration and longevity. By partnering with LYRADRIVE, customers secure not just a component, but a commitment to quality and expertise that enhances machine uptime and operational productivity.