How to Increase the Service Life of Slewing Bearings

What is a Light Load Slewing Bearing

Light Load Slewing Bearing refers to a compact, often single-row ball bearing designed to facilitate rotational movement under relatively moderate axial, radial, and moment loads. While they share the fundamental design principle of their heavier counterparts—enabling rotation between structures—their construction is optimized for applications where space is limited and extreme force is not a primary concern. A Light Load Slewing Bearing typically features a lower cross-section height, a simpler sealing system, and may be constructed from different material grades compared to heavy-duty versions. They are engineered for smooth, low-friction operation in scenarios requiring precise movement without the immense power transmission needs of larger machinery. Despite their "light load" designation, their correct installation and maintenance are no less critical, as improper handling remains a leading cause of premature failure across all bearing classes.

How to Increase the Service Life of Slewing Bearings

Extending the operational lifespan of a slewing bearing is not a matter of chance but a direct result of deliberate and correct practices from the moment it is unboxed. The journey to maximum longevity begins with installation, is defined by daily operation, and is secured through unwavering maintenance. Ignoring any of these pillars will inevitably lead to reduced service life and costly unplanned downtime.

The absolute foundation of long bearing life is a flawless installation. The process begins long before the bearing is lifted into place, with a rigorous inspection of the mounting surface. The installation platform must be machined to a high degree of flatness. This is non-negotiable. If the flatness of the mounting surface is inferior to the parallelism of the slewing bearing itself, a catastrophic chain of events is set in motion. As the mounting bolts are tightened, the bearing will be forcibly pulled down to conform to the uneven surface. This action warps the bearing rings, causing elastic deformation. The precision-ground raceways inside the bearing become misaligned—a condition known as raceway misalignment. The perfect geometry guiding the rolling elements is destroyed, leading to inconsistent internal clearance, concentrated stress points, increased friction, and rapid, premature fatigue failure. The solution is to meticulously check the flatness with a precision straightedge and feeler gauges. Any low spots or imperfections must be carefully shimmed with precision ground pads to create a perfectly uniform mounting plane. Furthermore, both the bearing's mounting face and the platform must be scrupulously cleaned to be free of any dirt, paint splatter, or debris that could act as a shim and cause similar distortion.

A critically important yet frequently overlooked installation factor is the proper positioning of the bearing's soft zone. For heat treatment reasons, all slewing bearings have a soft zone—a section of the ring that remains unhardened. This area is always marked by the manufacturer, typically with a stamped 'S' and a plastic plug inserted in a nearby bolt hole. Installing the bearing with its soft zone directly in the main load path is a severe error, as this area has significantly reduced load-carrying capacity. To prevent this, the soft zone must be strategically positioned in a non-load-bearing or minimally stressed area of the machine's operation cycle. For instance, inlifting equipment like mobile cranes or tower cranes, the industry best practice is to orient the soft zone 90 degrees away from the direction of the boom. Additionally, for double-row bearings, the soft zones of the inner and outer rings should be staggered by 180 degrees to distribute this inherent structural characteristic optimally, ensuring no single point is consistently weak.

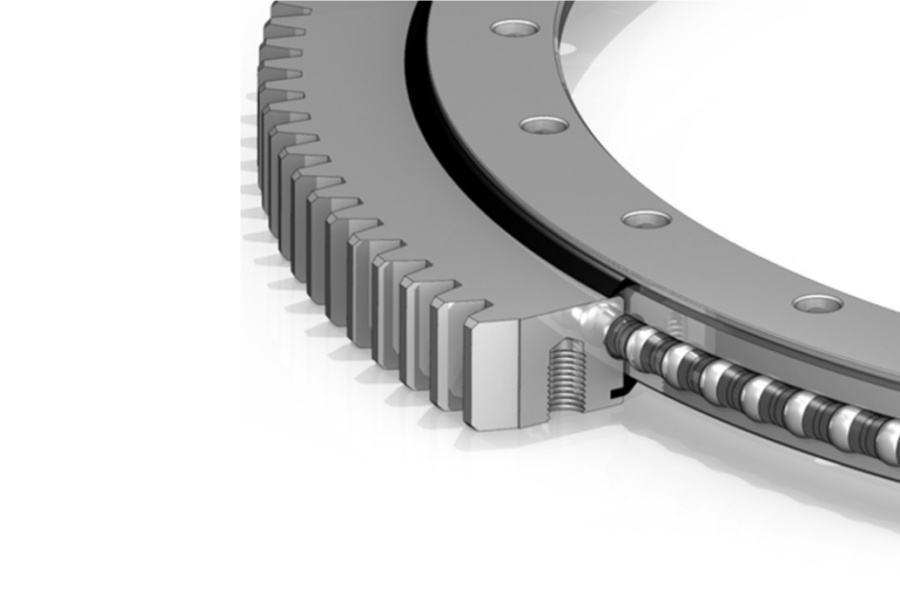

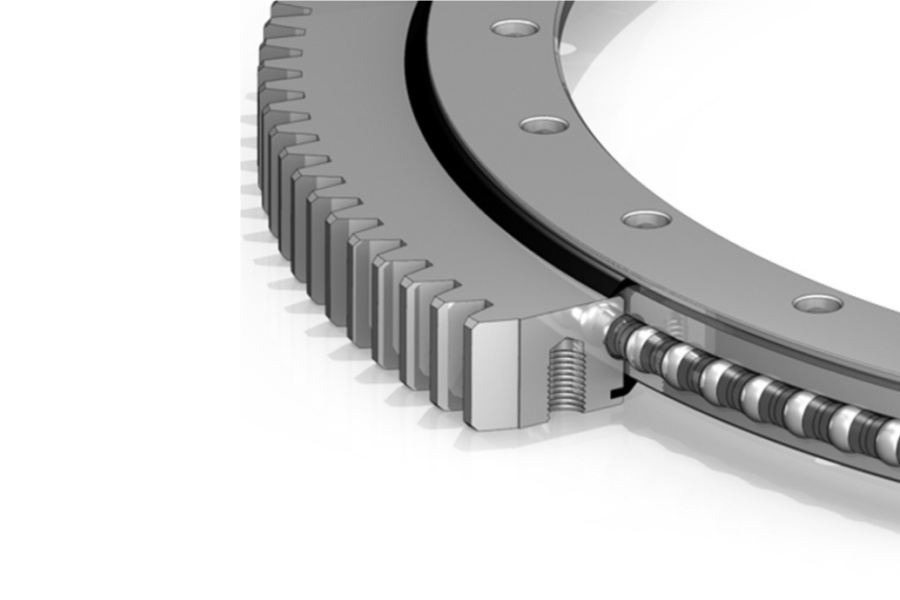

Optimal gear meshing is paramount for geared slewing bearings. Manufacturers facilitate this by marking the point of maximum radial runout on the gear teeth, often with a spot of colored paint. This point represents the theoretical largest distance from the true center of rotation. To ensure smooth operation, minimize noise, and prevent premature tooth wear, the drive pinion must be meshed with the gear at this precisely marked location. The backlash—the clearance between the pinion and gear teeth—must be meticulously adjusted according to the manufacturer's specifications or relevant national standards (like GB standards in China) using a feeler gauge. An incorrect backlash setting, whether too tight or too loose, generates excessive dynamic loads, accelerates wear on both the gear and the pinion, and introduces destructive vibrations that travel through the entire structure, negatively impacting the bearing's raceways and other connected components.

Beyond installation, operational discipline is the next pillar of longevity. The most destructive operational habit is overload. Every slewing bearing has clearly defined load capacity limits. Exceeding these limits, even briefly, subjects the raceways and rolling elements to stresses that exceed the material's yield strength. This results in plastic deformation (brinelling), creating permanent dents that disrupt smooth rolling motion and act as initiation points for fatigue cracks. Adhering to the rated capacity is the simplest yet most effective way to preserve the structural integrity of the bearing.

Finally, a proactive and preventive lubrication schedule is the lifeblood of the bearing. Lubrication serves to separate metal surfaces, reduce friction, dissipate heat, and protect against corrosion. For light load bearings, which often have less robust sealing systems, using the correct type of high-quality grease and adhering to a strict regreasing interval is critical. Contamination by abrasive particles or moisture is a primary killer of bearings. Regularly inspecting seals for damage and purging old grease (which may hold contaminants) during relubrication are essential maintenance tasks that directly prevent abrasive wear and corrosion, thereby drastically extending the service life of the unit.

Characteristics of Light Load Slewing Bearing

Light Load Slewing Bearings are defined by a specific set of characteristics that make them ideal for their intended applications. Their most notable feature is their compact and lightweight design, featuring a low cross-sectional height which allows for integration into space-constrained machinery without compromising performance. They are primarily configured with a single row of balls, which provides an excellent balance of load capacity and low friction for smooth, efficient rotation. The materials used are often optimized for cost-effectiveness and performance under moderate loads, potentially utilizing different steel grades or heat treatment processes than heavy-duty bearings. Their integrated sealing systems are typically simpler, often consisting of single-lip non-contact or lightly contacting seals, designed to retain grease and exclude larger contaminants without introducing significant drag torque. Despite their lighter duty classification, they still maintain the core functionalities of standard slewing bearings, including mounting holes for easy installation and often offering optional integrated gear teeth for drive capabilities. Their design prioritizes economical efficiency, precise motion, and quiet operation under manageable load conditions.

Applications of Light Load Slewing Bearing

The versatility and compact form factor of Light Load Slewing Bearings make them suitable for a vast array of applications across numerous industries where heavy loads are not a primary factor. A common application is in light-duty material handling equipment, such as small robotic arms used in assembly lines, pick-and-place units, and rotary tables on indexing equipment. The agricultural sector utilizes them in smaller machinery attachments, like seeders, sprayers, or the rotating platforms on certain types of trailers. They are found in a multitude of industrial machinery, including light-duty welding positioners, packaging equipment, and rotary feeders. In the realm of renewable energy, they can be used in solar tracking systems to precisely orient panels toward the sun throughout the day. Furthermore, they are present in various medical equipment for precise rotational positioning, in recreational vehicles for antenna or sensor platforms, and in countless other machines that require reliable, controlled rotation without the extreme forces seen in mining or heavy construction.

What Factors Influence the Price of Light Load Slewing Bearing

The cost of a Light Load Slewing Bearing is influenced by several interconnected factors that reflect its design, manufacturing complexity, and material composition. The physical size and dimensions, particularly the outer diameter and cross-sectional height, are primary drivers, as they determine the amount of raw material required. The inclusion of optional features, most notably precision-machined gear teeth (internal or external), adds significant machining time and cost. The material specification is another key factor; standard carbon steel might be used for very light duties, while higher-grade alloy steels or specific coatings will increase the price. The required precision tolerance grade also impacts cost; bearings manufactured to tighter tolerances for applications requiring minimal runout and smooth operation demand more advanced machining and quality control. The type and quality of accessories, such as seals (standard rubber vs. advanced polyurethane) and the inclusion of pre-drilled lubrication fittings, add to the overall cost. Finally, order volume plays a significant role; a large production run allows for economies of scale, significantly reducing the unit cost compared to a small custom order for a prototype or specialized machine.

Supplier of Light Load Slewing Bearings

For designers and engineers seeking reliable and precision-engineered rotational solutions for light to medium-duty applications, LYRADRIVE presents itself as a capable and experienced supplier. The company specializes in the design and manufacturing of a wide range of slewing products, including high-performance Light Load Slewing Bearings that meet rigorous quality standards. LYRADRIVE's focus on engineering excellence ensures that even their compact bearings offer optimal performance, durability, and smooth operation. They provide valuable technical support to assist with selection, integration, and maintenance, ensuring customers achieve the maximum possible service life from their components. By choosing LYRADRIVE, customers partner with a supplier dedicated to delivering quality and reliability, contributing directly to the enhanced performance and longevity of their end products.