Reasons for Excessive Tilting Play in Slewing Rings

What is a Heavy load slewing bearing

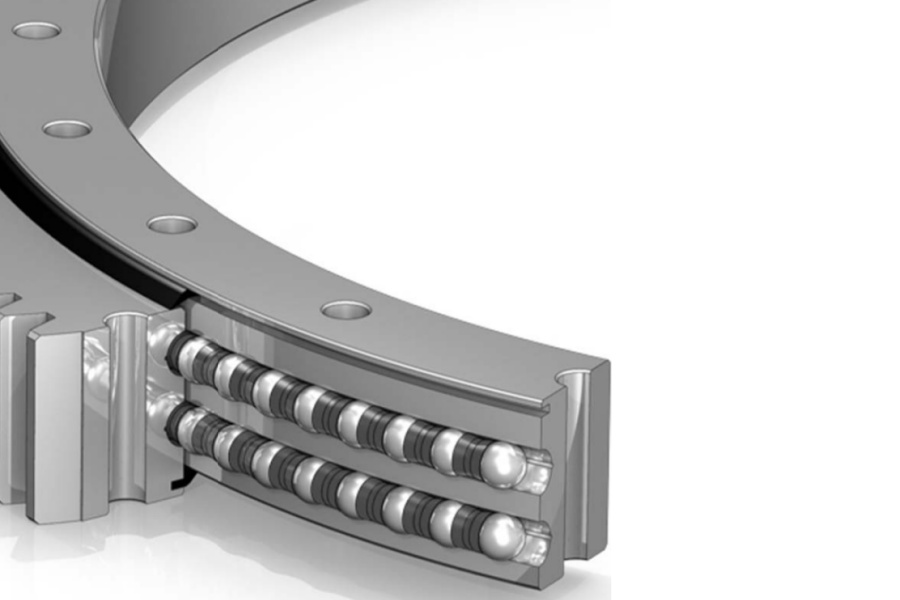

Heavy load slewing bearings are highly engineered, large-diameter rotational bearings designed to support exceptionally high combination loads while facilitating smooth and controlled rotation between machine components. Unlike standard bearings that typically handle a single load type, these robust assemblies are fundamentally designed to manage simultaneous axial, radial, and moment (tilting) loads, making them indispensable in the most demanding industrial applications. Their construction typically features a single or double row of rolling elements (balls or rollers) housed within robust inner and outer rings. Key distinguishing features include integrated gear teeth (on the inner or outer ring) for drive transmission, numerous mounting holes for direct bolting to structures, and sophisticated sealing systems to protect against contaminants. A Heavy load slewing bearing is not merely a component; it is the core structural and rotational element that defines the performance envelope of the entire machine, bearing the weight of the load and the stresses of operation with precision.

Reasons for Excessive Tilting Play in Slewing Rings

Excessive tilting play, often felt as a noticeable rocking motion or clear visual movement between the upper and lower structures of a machine, is a severe condition that demands immediate attention. It signifies that the bearing is not being held securely or has suffered internal damage, directly threatening operational safety and component life. The causes are typically interlinked and can be categorized into several critical areas.

The most common and easily addressable cause is loosened mounting bolts. These bolts are responsible for creating a rigid, unified connection between the slewing bearing and the host machine's structure. When these bolts are not tightened to the specified pre-load torque during installation, or when they loosen over time due to vibration and dynamic loads, a microscopic gap forms between the bearing ring and the mounting surface. Under load, this gap allows the bearing to shift minutely, manifesting as tilting play. This seemingly small movement induces catastrophic stress concentrations on the remaining tight bolts and causes fretting corrosion at the interface surfaces. The first and most crucial diagnostic step when encountering play is to immediately check the torque of all mounting bolts on both the inner and outer rings against the manufacturer's specifications, retightening them in a star pattern if necessary.

A more structurally complex issue is insufficient rigidity in the supporting framework. A Heavy load slewing bearing is engineered to be supported by a structure of equal or greater rigidity. If the surrounding steel framework, chassis, or platform lacks adequate reinforcement, it will act like a spring instead of a solid foundation. When subjected to heavy or off-center loads, the framework itself elastically deforms or flexes. Since the slewing bearing is bolted to this flexing surface, it is forced to distort along with it. This distortion warps the bearing's raceways, preventing the rolling elements from moving smoothly and causing the entire assembly to tilt and rock under load. This problem cannot be solved by tightening bolts; it requires a fundamental reinforcement of the supporting steel structure to eliminate flexure and provide the unwavering foundation the bearing requires.

Operational abuse, particularly in the form of severe overload or consisten (partial load), is a destructive force that directly leads to play. Every slewing bearing has meticulously calculated load ratings. Exceeding these ratings, even momentarily, applies forces that surpass the material's yield strength. This can cause immediate plastic deformation (brinelling) of the raceways, creating permanent dents at the contact points of the rolling elements. While a single overload event might cause initial damage, chronic overloading accelerates fatigue, leading to widespread spalling where chunks of material break away from the raceway. This process effectively increases the internal clearance of the bearing far beyond its original design specifications. The result is excessive axial and radial play, manifesting as the dangerous tilting and shaking observed during operation. Adhering to the rated capacity is not a suggestion but a strict requirement for preventing this type of catastrophic internal failure.

Finally, long-term operation under these abusive conditions culminates in raceway compaction and failure, leading to a catastrophic increase in clearance. The continuous overloading and (partial load) described above progressively degrade the raceway. The rolling elements, under immense pressure, literally crush the micro-structure of the hardened steel raceway. This causes the grooves to widen and deepen beyond salvageable limits, and the geometry that once precisely guided the rolling elements is destroyed. The internal (clearance) becomes so large that the bearing can no longer maintain its structural integrity, resulting in massive, uncontrolled tilting play. At this advanced stage, the bearing is irreparably damaged. No amount of bolt tightening or structural reinforcement can fix it; the only solution is a complete replacement of the slewing ring unit to restore machine safety and function.

Characteristics of Heavy load slewing bearing

Heavy load slewing bearings are defined by a set of characteristics that enable them to perform under extreme conditions. Their most critical feature is the ability to handle complex combination loads—axial, radial, and moment loads—simultaneously, which is a capability beyond the scope of standard bearings. They are manufactured from high-quality, through-hardened alloy steels (such as 42CrMo4) to provide a tough core resilience and a hard, wear-resistant surface on the raceways. Integration is another key characteristic; they often feature precisely machined internal or external gear teeth that are induction hardened for superior wear resistance, allowing them to act as both a bearing and a drive gear. Their design incorporates high load-carrying capacity through optimized raceway geometry and the use of large-diameter rolling elements. Robust multi-lip seals are integrated to protect the internal mechanisms from abrasive contaminants and retain lubrication. Furthermore, they are engineered for durability and longevity, with designs that often include hardened and ground raceways for smooth operation and reduced friction. Customization is also a standard characteristic, with manufacturers offering variations in gear type, seal material, bolt hole patterns, and lubrication systems to meet specific application demands.

Applications of Heavy load slewing bearing

The unique capabilities of Heavy load slewing bearings make them critical components across a vast spectrum of heavy industries. Their primary role is wherever heavy loads must be rotated with precision and reliability. In the construction sector, they are the pivotal heart of excavators, enabling the 360-degree rotation of the house structure, and are equally vital in mobile cranes, tower cranes, and concrete pump trucks. The wind energy industry relies on massive, highly durable slewing bearings for both the yaw system (to rotate the nacelle to face the wind) and the pitch system (to adjust the angle of the blades for control and efficiency). In material handling, these bearings are found in the stacker reclaimers that manage bulk materials in ports and mines, as well as in heavy-duty robotic welding arms and turntables used in manufacturing. The mining industry utilizes them in draglines, mining shovels, and tunnel boring machines, where they operate under incredibly harsh conditions and extreme loads. Other applications include military equipment like radar platforms and tank turrets, aerospace launchers, and even large-scale medical imaging devices such as CT scanners.

What Factors Influence the Price of Heavy load slewing bearing

The cost of a Heavy load slewing bearing is not arbitrary; it is a direct reflection of its engineering, materials, and manufacturing complexity. Several key factors determine the final price. Primarily, the physical size and dimensions (outer diameter, height, cross-section) are major drivers, as they dictate the amount of raw material required. The required load capacity is paramount; a bearing rated for higher axial, radial, and moment loads requires a more robust design, larger rolling elements, and often higher-grade material, increasing cost significantly. The material grade and the specific heat treatment processes (through-hardening vs. case-hardening) also contribute to the cost, with premium alloys and specialized treatments commanding a higher price. Manufacturing complexity is a huge factor; the inclusion of precision-ground gear teeth, custom sealing solutions, special drilling patterns for mounting holes, and non-standard lubrication fittings all add machining time and expense. The required precision class and tolerance levels impact cost, as bearings for high-precision applications like medical or aerospace equipment require more advanced manufacturing and rigorous quality control. Finally, economies of scale apply; a custom-designed, one-off bearing will be far more expensive per unit than a standard model produced in large quantities for a common machine platform.

Supplier of Heavy load slewing bearings

For engineers and operators seeking reliable solutions for demanding rotational applications, LYRADRIVE stands as a proficient manufacturer and supplier of high-performance Heavy load slewing bearings and drives. The company specializes in the design and production of a comprehensive range of precision slewing products engineered for durability, maximum load capacity, and long service life in the most challenging environments. LYRADRIVE's offerings are characterized by advanced engineering, stringent quality control throughout the manufacturing process, and the use of high-grade materials to ensure unwavering performance. They provide essential technical support, from initial design integration and selection assistance to maintenance guidance, ensuring optimal performance and longevity of their products. By choosing LYRADRIVE as a partner, customers invest in a critical component backed by proven expertise and a commitment to reliability, directly contributing to enhanced machine uptime and operational safety.