Slewing Bearing Application in Stacker Reclaimers

What is Light Load Slewing Bearing

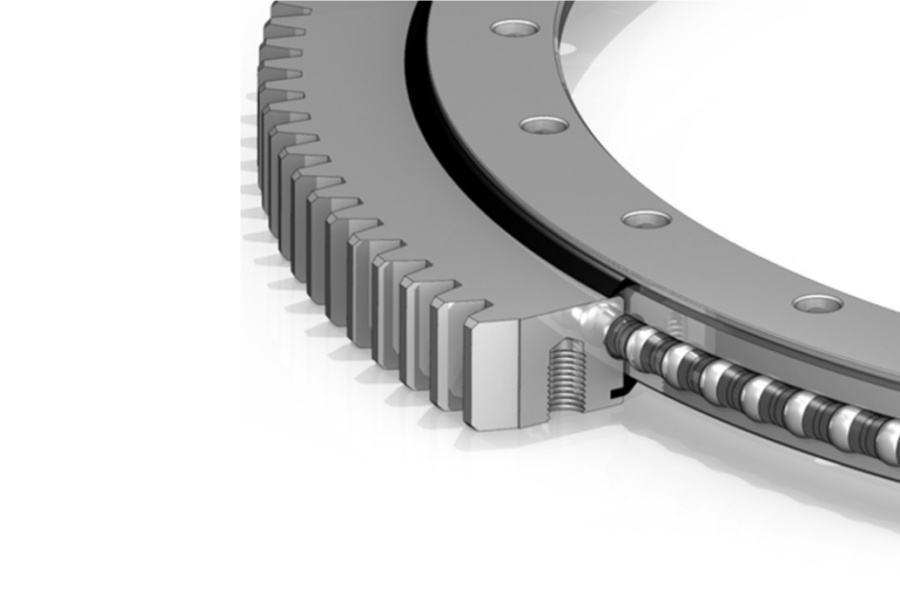

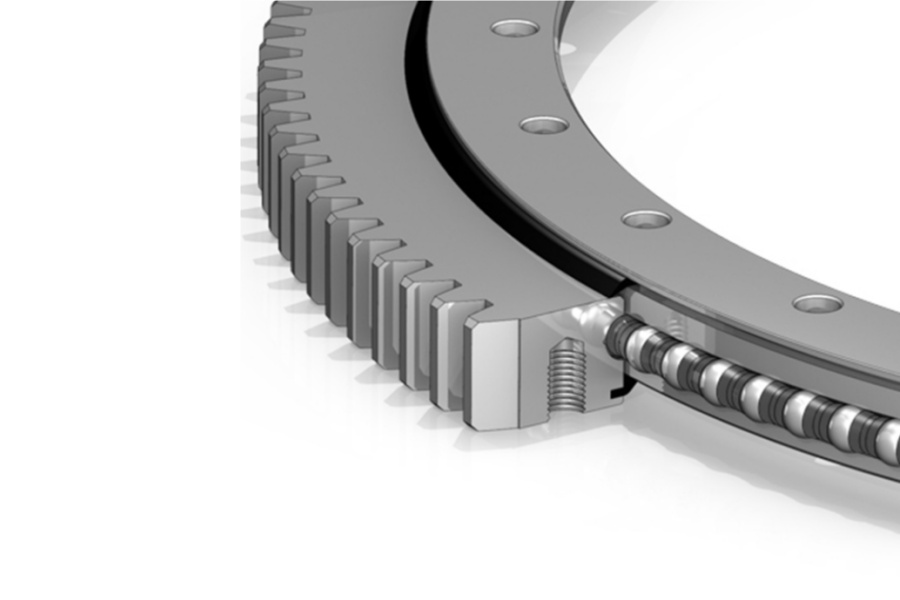

Light Load Slewing Bearing refers to a class of slewing rings engineered for applications with moderate axial, radial, and moment loads relative to their size. Characterized by optimized cross-sections and material efficiency, these bearings prioritize cost-effectiveness without compromising essential performance. They typically feature single-row ball or crossed roller designs, simplified sealing, and may omit integrated gearing. Light load slewing bearings deliver reliable rotation for equipment where extreme forces are absent but precise motion and durability remain essential.

Slewing Bearing Application in Stacker Reclaimers

Slewing bearings serve as the fundamental rotational interface in stacker reclaimers, enabling critical functions:

Boom Rotation:

Mounted at the base of the stacking or reclaiming boom, the slewing bearing facilitates precise horizontal slewing (±110° to ±165° typically). This allows controlled material stacking in radial patterns or selective reclaiming from stockpile segments. Light load bearings are often suitable here, handling the boom's weight and inertial forces during controlled slewing motions.

Bucket Wheel Arm Positioning:

In bridge-type reclaimers, slewing bearings enable the rotation of the entire bridge structure or the bucket wheel arm. This provides lateral traversal across the stockpile for comprehensive material recovery. The moderate, predictable loads make light load slewing bearings a viable and economical choice.

Tripper Car Turntables (Less Common):

Some stacking systems utilize slewing bearings within tripper cars for directional discharge adjustments. Light load bearings suffice for these auxiliary functions under relatively stable loads.

Advantages Over Alternatives:

Simplified Installation & Structure: Compared to wheel-and-rail or conical roller systems, slewing bearings offer a compact, integrated solution. They mount directly between the rotating superstructure (boom, bridge) and the fixed base, eliminating complex track systems and associated maintenance.

Integrated Load Handling: Slewing bearings inherently absorb the tilting moments generated by the cantilevered boom during operation and wind loading, enhancing structural stability.

Smooth, Precise Control: Precision-machined raceways ensure smooth, low-vibration rotation, crucial for accurate stacking and reclaiming operations.

Reduced Maintenance Burden: Properly sealed and lubricated slewing bearings require less frequent maintenance than exposed rail or wheel systems prone to contamination and wear.

Challenges & Mitigation:

Replacement Complexity: Replacing a large, integrated slewing bearing is a major undertaking requiring disassembly.

Solution: This underscores the importance of selecting high-quality bearings (like light load variants from LYRADRIVE designed for longevity) and implementing rigorous preventive maintenance (greasing, bolt checks, wear monitoring) to maximize service life (typically 7-15+ years, potentially exceeding 25 years with premium components and care).

Light Load Slewing Bearing Characteristics

Designed for efficiency in moderate-duty applications:

Optimized Cross-Section: Reduced height and material usage compared to heavy-duty bearings, lowering weight and cost.

Efficient Load Handling: Engineered for defined axial, radial, and moment load capacities common in light-to-medium machinery.

Simplified Sealing: Often features single or double lip seals adequate for less severe environments.

Material Efficiency: Utilizes high-quality carbon or alloy steels with appropriate hardening (e.g., induction hardening), balancing performance and cost.

Gearing Optional: Internal or external gears can be included if direct drive is needed, but many light load applications use external drive mechanisms.

Ease of Integration: Standardized mounting patterns and pre-machined features simplify installation.

Cost-Effectiveness: Primary advantage, offering reliable performance at a lower initial investment.

Light Load Slewing Bearing Applications

Beyond stacker reclaimers, these bearings excel in:

Light Industrial Turntables: Assembly stations, welding positioners, display platforms.

Material Handling Equipment: Moderate-duty rotators, indexers, conveyor diverters.

Solar Tracking Systems: Azimuth and elevation drives for smaller solar arrays.

Packaging & Food Processing Machinery: Rotary feeders, filling stations, inspection tables.

Medical & Rehabilitation Equipment: Patient lift rotators, scanning table bases.

Agricultural Machinery: Grain bin sweeps, fertilizer spreader bases.

Aerial Work Platforms: Rotational bases for light booms or baskets.

Factors Influencing Light Load Slewing Bearing Price

Cost is driven by design and production choices:

Size & Basic Capacity: Larger diameter and higher nominal load ratings increase material costs.

Bearing Type: Crossed roller designs generally cost more than single-row ball bearings for equivalent size.

Material & Heat Treatment: Standard carbon steel is most economical; alloy steels or specialized hardening add cost.

Manufacturing Precision: Tighter tolerances on raceways, mounting surfaces, and holes require more advanced machining, raising price.

Sealing: Basic lip seals are low-cost; multi-lip seals or specialized elastomers (FKM, HNBR) for harsh environments increase price.

Gear Teeth: Adding gears (module size, helical vs. spur, hardening) significantly impacts cost.

Mounting Features: Complexity of bolt hole patterns, counterbores, or pilot diameters adds machining steps.

Quantity: Significant per-unit cost reduction with bulk purchases due to setup amortization.

Quality Control: Basic inspection keeps costs down; advanced NDT (MPI, UT) or load testing adds expense.

Brand & Origin: Established brands command premiums; manufacturing location affects labor/logistics costs.

Customization: Standard catalog bearings are cheapest; non-standard sizes, special seals, or unique features incur engineering and setup costs.

Light Load Slewing Bearing Supplier LYRADRIVE

LYRADRIVE supplies engineered light load slewing bearings optimized for performance and value in applications like stacker reclaimers. Their solutions balance durability, precision, and cost-efficiency, offering reliable rotation for moderate-duty industrial and mobile equipment, backed by technical support to ensure optimal selection and service life.