Six Major Causes of Excavator Slewing Bearing Overheating

What is Excavator Slewing Bearing

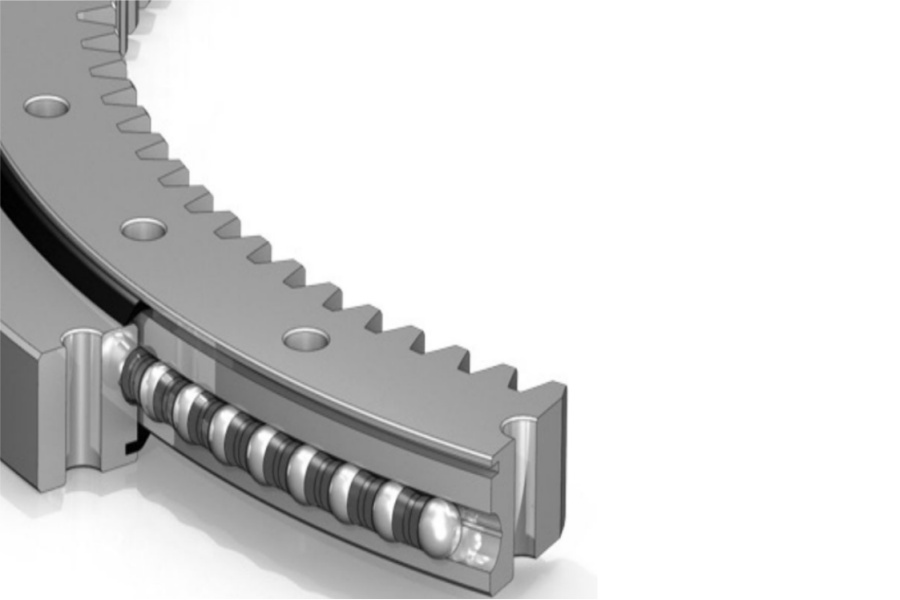

Excavator Slewing Bearing is the critical large-diameter rotational component mounted between the excavator's upper structure (house) and the undercarriage. It enables 360-degree rotation under extreme combined loads (axial, radial, and tilting moments) generated during digging and swinging operations. Typically featuring a robust single-row, four-point contact ball design with an internal gear ring, integrated seals, and numerous high-strength mounting bolts, it directly transmits motion from the swing motor pinion while supporting the entire weight and dynamic forces of the upper works. Its reliable, smooth operation is fundamental to excavator performance and safety.

Six Major Causes of Excavator Slewing Bearing Overheating

Overheating indicates excessive friction, leading to accelerated wear, lubricant breakdown, seal damage, and catastrophic bearing failure. The six most common causes are:

Excessive Bearing Preload (Over-Constrained Installation):

Cause: Incorrect installation where the bearing inner or outer ring is forced into an excessively tight fit (excessive interference fit) on its mounting surface. This creates high internal radial preload, compressing the rolling elements and raceways even before external loads are applied. This drastically increases rolling friction and generates significant heat.

Solution: Strictly adhere to the excavator manufacturer's specified tolerances (e.g., H7 tolerance for the bore, k6 for the shaft) for mounting surfaces. Use proper installation tools and techniques – never use hammer blows directly on the bearing rings. Ensure mounting surfaces are clean, burr-free, and perfectly flat.

Seal Friction and Drag:

Cause: Lip seals generate inherent drag. This friction intensifies dramatically if seals are damaged, hardened, dry, or misaligned. The "aluminum three-layer ring seal" reference likely points to complex multi-lip seals common in excavators; friction here can be a major heat source, especially at start-up or low speeds.

Solution: Always lubricate the seal lips and the seal housing bore with compatible grease before installation. Regularly inspect seals for damage and replace them promptly. Ensure seals are correctly seated and aligned. Using seals designed for low friction can help, but prioritize contamination exclusion.

Over-Lubrication (Excessive Grease Volume):

Cause: Injecting too much grease into the raceway cavity creates high internal pressure. This pressure forces grease past seals (causing leaks), increases viscous drag as rolling elements churn through the excess grease, and traps heat within the bearing. Overfilled gear cavities can also cause similar issues.

Solution: Follow the manufacturer's recommended lubrication schedule and quantity. Purge old grease properly by injecting new grease while slowly rotating the excavator upper structure. Stop injecting when fresh grease appears at the purge port/seal lips. Never pump grease into a stationary bearing under high pressure.

Incorrect or Degraded Lubricant:

Cause: Using grease with the wrong base oil viscosity, thickener type, or additive package for the operating temperature and load conditions. Grease can also degrade over time due to oxidation, contamination (water, dirt), or mechanical shearing, losing its lubricity and becoming stiff or abrasive. Both scenarios increase friction and heat generation.

Solution: Always use the grease type specified by the excavator or bearing manufacturer (typically a high-quality, extreme pressure (EP), lithium complex or polyurea grease with suitable viscosity). Establish a strict grease replacement schedule based on operating hours and conditions. Monitor grease condition during purging.

Under-Lubrication (Insufficient Grease):

Cause: Infrequent greasing, clogged lubrication channels, or grease gun failures lead to inadequate lubricant film between rolling elements and raceways. This results in metal-to-metal contact, dramatically increasing friction, wear, and localized heat generation ("hot spots"). Low oil level in gear cavities (if oil-lubricated) has the same effect on gears.

Solution: Implement a rigorous, documented lubrication schedule based on excavator usage (hours worked). Ensure grease zerks are accessible and functional. When greasing, rotate the upper structure slowly to distribute grease evenly. For gear cavities, maintain the oil level just below the cage bottom (if applicable) or as specified.

Internal Misalignment or Component Rubbing:

Cause: Loose or broken mounting bolts allow the bearing rings to shift slightly relative to each other under load, disrupting the designed internal geometry. This misalignment increases friction in the raceways. Additionally, if the inner ring (or a spacer/adapter) is not securely fixed to the shaft, axial movement can occur, causing the inner ring to rub against seals or other stationary components, generating significant localized heat. Misalignment can also cause rollers to skew and scuff against flange guides.

Solution: Regularly check and tighten mounting bolts to the specified torque using the correct cross-bolting sequence. Inspect bolts for stretching or damage and replace them as needed. Ensure the inner ring is securely clamped axially against a shoulder using appropriate locking methods (nuts, end plates). Verify correct spacer/adapter installation and that rollers are correctly aligned within their guides. Address any structural issues in the excavator frame causing misalignment.

Excavator Slewing Bearing Characteristics

These bearings are engineered for extreme duty:

Massive Combined Load Capacity: Designed to withstand severe axial digging forces, radial swing loads, and tilting moments simultaneously.

Single-Row Four-Point Contact Ball Design: Predominant configuration offering optimal load capacity, compactness, and smooth rotation for excavators.

Robust Internal Gear Ring: Hardened and ground teeth mesh directly with the swing motor pinion for efficient torque transmission.

Heavy-Duty Sealing: Multi-lip seals (often with labyrinth features) crucial for excluding abrasive dirt, mud, and water in harsh environments.

High-Strength Construction: Manufactured from case-hardened alloy steel for exceptional surface hardness and a tough, shock-resistant core.

Precision Mounting: Numerous high-tensile bolts ensure secure attachment to the carbody and revolving frame.

Pre-Lubricated: Typically factory-filled with high-performance grease, though field replenishment is essential.

Excavator Slewing Bearing Applications

The primary application is singular and critical:

Hydraulic Excavator Swing Function: Provides the essential 360-degree rotational interface between the excavator's upper works (house - cab, engine, boom, arm, bucket, counterweight) and its undercarriage (track frame or wheels). This enables digging, lifting, and material placement in any direction without moving the tracks, fundamental to all hydraulic excavator operations from compact to mining class.

Factors Influencing Excavator Slewing Bearing Price

Cost is driven by engineering complexity and durability requirements:

Excavator Size & Class: Larger bearings for 30-ton+ machines cost significantly more than those for mini-excavators.

Load Rating: Higher axial/radial/moment capacity demands larger rollers, stronger materials, and robust design, increasing price.

Manufacturing Precision: Tight tolerances for raceways, gears (DIN/AGMA standards), and mounting surfaces require advanced grinding, raising costs.

Material & Heat Treatment: Premium alloy steel and specialized case hardening processes are major cost factors.

Gear Specifications: Gear module size, helix angle, hardness depth, and precision class significantly impact price.

Sealing System: Multi-lip seals with HNBR/FKM compounds for extreme conditions (IP69K) cost more than basic seals.

Bolt Configuration: Number, size, and hole pattern complexity add to manufacturing cost.

Brand & Quality Tier: OEM parts command premium prices; high-quality aftermarket bearings offer savings; budget options risk premature failure.

Certifications: ISO 9001, DNV-GL, or API certifications add cost through rigorous testing (NDT, load testing).

Quantity & Urgency: Bulk fleet purchases reduce unit cost; expedited production/shipping incurs premiums.

Excavator Slewing Bearing Supplier LYRADRIVE

LYRADRIVE is a trusted supplier of high-performance excavator slewing bearings, engineered to mitigate overheating risks through precision manufacturing, optimal heat treatment, and advanced sealing solutions. They provide durable replacements and OEM-grade components designed for reliable operation under the demanding conditions of excavation work, backed by technical support.