How to Repair Hydraulic Excavator Slewing Bearing

What is Excavator Slewing Bearing

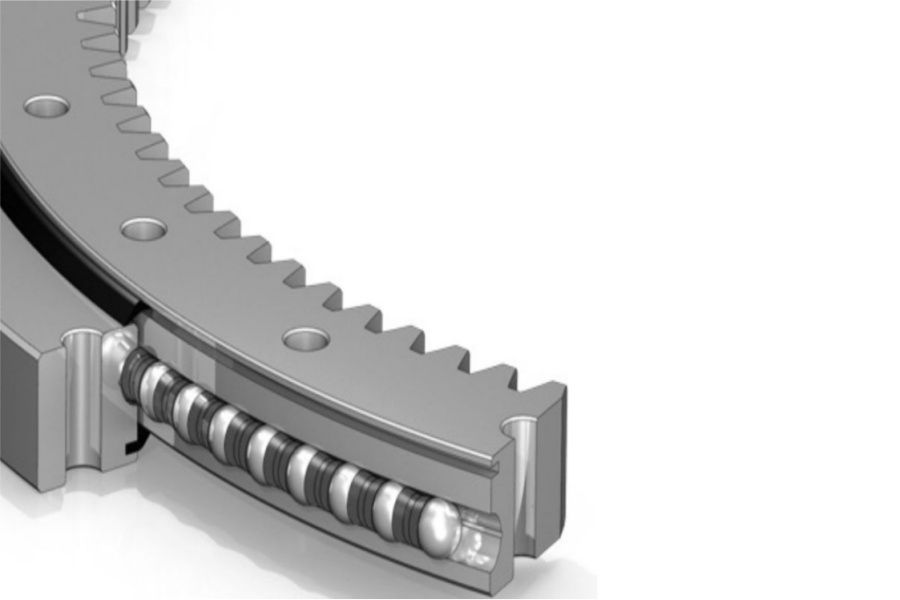

Excavator Slewing Bearing is the large-diameter, precision-engineered rotational component mounted between the excavator's upper structure (house) and the undercarriage. It enables the 360-degree rotation of the upper works (cab, boom, arm, bucket, counterweight) relative to the tracks or wheels. Specifically designed to handle the extreme combined loads inherent in excavator operation – massive axial forces from digging, significant radial loads during swinging, and substantial tilting moments – it typically features a robust single-row, four-point contact ball design with an internal gear ring. This integrated gear meshes directly with the pinion gear of the excavator's swing motor and reduction gearbox, transmitting the rotational force. Seals protect the internal rolling elements and raceways from contamination, and numerous high-strength bolts secure it to both structural halves. Its reliable function is paramount for machine stability, precise positioning, and overall productivity.

How to Repair Hydraulic Excavator Slewing Bearing

Repairing an excavator slewing bearing involves thorough inspection, addressing specific failure points, and meticulous reassembly. Key repair and maintenance procedures include:

Raceway Lubrication Maintenance:

Problem: Rolling elements and raceways are high-wear zones. Inadequate or improper lubrication accelerates failure.

Repair/Maintenance: Regularly purge and replenish grease using a manual grease gun specifically designed for high pressure. Access grease zerks on the bearing's outer ring. Crucially, rotate the excavator upper structure SLOWLY and CONTINUOUSLY while injecting grease. This ensures the new grease distributes evenly throughout the entire raceway cavity, displacing old grease and contaminants out through the purge port/seal lips. Avoid "static greasing" (injecting while stationary) or "single-point greasing" (only greasing from one zerk without rotation), as this creates pressure pockets, damages seals, leads to leaks, and allows contaminant ingress. Always use the grease type specified by the bearing or excavator manufacturer; mixing greases can cause incompatibility and premature failure. If grease is severely degraded, a complete purge and refill is necessary.

Gear Ring and Pinion Maintenance:

Problem: Gear teeth wear, corrosion, or lack of lubrication increases backlash, causes noise, and can lead to tooth failure.

Repair/Maintenance: Remove the metal inspection cover(s) on the excavator's swing platform base. Inspect the gear teeth on both the slewing bearing's internal ring and the swing motor pinion for wear patterns (pitting, spalling), chipping, cracks, and adequate grease coverage. Check the condition of the rubber gasket under the inspection cover. If damaged, cracked, or hardened, REPLACE IT IMMEDIATELY. A failed gasket allows water and dirt ingress into the gear lubrication chamber, washing away grease and causing rapid corrosion and wear. Apply fresh, manufacturer-approved gear grease to the teeth during reassembly.

Inner and Outer Seal Inspection and Replacement:

Problem: Damaged seals allow contaminants (dirt, water, abrasive particles) into the raceway or permit grease leakage out. Seal failure on the swing motor reduction gearbox can also cause gear oil to leak into the slewing bearing gear cavity.

Repair/Maintenance: Visually inspect both the inner (facing the center) and outer seals of the slewing bearing for cuts, tears, excessive hardening, cracking, or detachment. Check for signs of grease leaking past the seals. If seals are damaged, they MUST BE REPLACED. Replacing seals often requires significant disassembly (partial or full removal of the bearing). Use only OEM or high-quality replacement seals designed for the specific bearing model and excavator application. Simultaneously, inspect the seals on the swing motor reduction gearbox output shaft. If these are leaking gear oil into the gear cavity, it dilutes the grease, reduces lubricity, increases temperature, and can cause the thinned grease to bypass the slewing bearing's inner seal, contaminating the raceway – leading to catastrophic bearing failure. Replace faulty motor seals promptly.

Mounting Bolt Torque Verification and Replacement:

Problem: Loose or broken mounting bolts are a primary cause of slewing bearing failure. Loose bolts create uneven load distribution, excessive movement, impact loads, and ultimately lead to more bolts loosening or fracturing, raceway damage, and structural issues.

Repair/Maintenance: Adhere strictly to the excavator manufacturer's bolt tightening schedule and torque specifications. Typically, check bolt preload torque:

After the first 100 hours of operation.

Again at 500 hours.

Subsequently every 1000 operating hours.

Use a calibrated torque wrench. Follow the CORRECT TIGHTENING SEQUENCE: tighten bolts gradually in a star or cross pattern (180 degrees apart) over multiple passes to ensure even preload distribution across the entire flange. Never tighten bolts sequentially in a circle. If bolts are found loose, investigate the cause (settling, stretch, corrosion). Crucially: Bolts that have been repeatedly tensioned and loosened experience work hardening and lose their ability to maintain preload. When re-tightening bolts that have been in service (even if not fully loose), increase the final torque value by 30-50 N·m ABOVE the standard specification to compensate for this loss of elasticity and achieve the correct clamping force. Replace any bolts showing signs of stretching (necking), corrosion, damaged threads, or if torque cannot be achieved. Always use the correct grade (high tensile strength) bolts specified by the manufacturer.

Gear Backlash Adjustment:

Problem: Excessive backlash between the slewing bearing's internal gear and the swing motor pinion causes noisy operation, impact loading, accelerated wear, and potential tooth breakage. Insufficient backlash causes binding and overheating.

Repair/Maintenance: Backlash adjustment is critical after bearing replacement or if inspection reveals excessive play. The adjustment mechanism varies by excavator model but typically involves shims or eccentric bushings on the swing motor/reduction gearbox mounting. Consult the specific excavator service manual for the correct procedure and specification. Before adjusting backlash, ensure all bolts securing the swing motor and reduction gearbox to the mounting bracket are properly tightened. Looseness here invalidates any backlash measurement. Use a dial indicator to measure backlash accurately at several points around the gear circumference. Adjust according to manufacturer specs, ensuring consistent backlash throughout the rotation. Re-check after final tightening.

General Repair Considerations:

Diagnosis: Thoroughly diagnose the root cause of any issue (e.g., seal failure causing contamination, loose bolts causing raceway brinelling) before repair.

Parts Quality: Use high-quality replacement parts (seals, bolts, grease) meeting OEM specifications.

Cleanliness: Maintain extreme cleanliness during any disassembly, inspection, or reassembly. Contamination is a major bearing killer.

Expertise: Major repairs, especially bearing replacement or structural work, require significant expertise and specialized equipment due to the weight and precision involved. Often best performed by qualified technicians.

Documentation: Always refer to the specific excavator and slewing bearing manufacturer's service manuals for procedures, torques, and specifications.

Excavator Slewing Bearing Characteristics

Excavator slewing bearings are defined by features engineered for extreme service:

Exceptional Load Capacity: Specifically designed to withstand the severe combination of axial (vertical), radial (side), and tilting moment (overturning) loads generated during digging, lifting, and swinging operations.

Single-Row Four-Point Contact Ball Design: Predominant configuration offering an optimal balance of high load capacity (in all directions), compactness, smooth rotation, and cost-effectiveness for excavator applications.

Internal Gear Ring: Integrated gear teeth cut into the inner ring mesh directly with the swing motor pinion, providing efficient torque transmission for rotation.

Robust Sealing: Multi-lip seals, often with labyrinth features, are essential to exclude abrasive dirt, mud, and water prevalent in construction environments and retain lubrication.

High-Strength Mounting: Features numerous bolt holes on both inner and outer rings for secure attachment to the excavator's carbody (undercarriage) and the revolving frame (upper structure), using high-tensile bolts.

Case-Hardened Races: Raceways undergo specialized heat treatment (case hardening) to create a hard, wear-resistant surface while maintaining a tough, shock-resistant core.

Pre-Greased & Sealed for Life (Often): Many are factory-filled with high-performance grease and sealed, though most excavator designs still incorporate provision for re-lubrication.

Excavator Slewing Bearing Applications

The primary application is fundamental and singular, yet critical:

Hydraulic Excavator Swing Function: Provides the essential 360-degree rotational interface between the excavator's upper works (house - containing the cab, engine, hydraulic pumps, boom, arm, bucket, counterweight) and its undercarriage (track frame or wheels). This enables the machine to dig, lift, and dump material in any direction without repositioning the tracks. It is used in all types and sizes of hydraulic excavators, from compact mini-excavators to massive mining shovels.

Factors Influencing Excavator Slewing Bearing Price

The cost is driven by numerous engineering and logistical factors:

Size and Excavator Class: Larger bearings for larger excavators (30-ton, 50-ton, 80-ton+) require exponentially more material and complex manufacturing, significantly increasing cost.

Load Capacity Rating: Bearings designed for higher axial, radial, and moment loads (common in demanding applications or larger machines) use more robust designs, larger rolling elements, and higher-grade materials, increasing price.

Manufacturing Precision: Precise machining of raceways, gear teeth (profile, pitch, hardness), mounting surfaces, and bolt holes is critical for performance and longevity. Tighter tolerances demand advanced processes and increase cost.

Material Quality: High-strength, case-hardened alloy steel is standard. Premium grades or special alloys for enhanced durability or corrosion resistance add expense.

Gear Specifications: Size (module), quality class (AGMA, DIN), tooth profile (straight vs. helical - helical is more complex), and hardening process of the internal gear ring impact cost.

Sealing System: High-performance, multi-lip seals designed for extreme environments (e.g., IP69K for high-pressure washdown, special elastomers for wide temperature ranges or chemical resistance) are more expensive than basic seals.

Bolt Hole Quantity and Configuration: The number, size, and pattern of mounting bolt holes add complexity to manufacturing.

Brand and Origin: Premium brands (OEM and established aftermarket) often command higher prices based on reputation, proven reliability, and R&D investment. Geographic origin influences manufacturing and logistics costs.

Replacement vs. OEM: Genuine OEM parts are typically the most expensive. High-quality aftermarket bearings offer cost savings but vary in quality. Low-cost aftermarket options carry significant risk.

Heat Treatment: Sophisticated case hardening and tempering processes are essential for the required surface hardness and core toughness, adding significant cost.

Quality Control & Certification: Rigorous Non-Destructive Testing (NDT - magnetic particle, ultrasonic), load testing, gear inspection, and material certifications add to the manufacturing cost.

Quantity: Purchasing single units is significantly more expensive per bearing than buying in bulk for a fleet.

Logistics & Urgency: Size and weight make shipping costly. Expedited shipping or remote location delivery adds premiums.

Excavator Slewing Bearing Supplier

LYRADRIVE is a recognized supplier of robust slewing bearings engineered for the demanding requirements of hydraulic excavators. They provide solutions encompassing both high-quality aftermarket replacements and potential OEM specifications, focusing on durability, precise load handling, and reliable performance under the harsh conditions typical of excavation work.