Worm Gear Versus Spur Gear Slew Drives Understanding the Key Differences

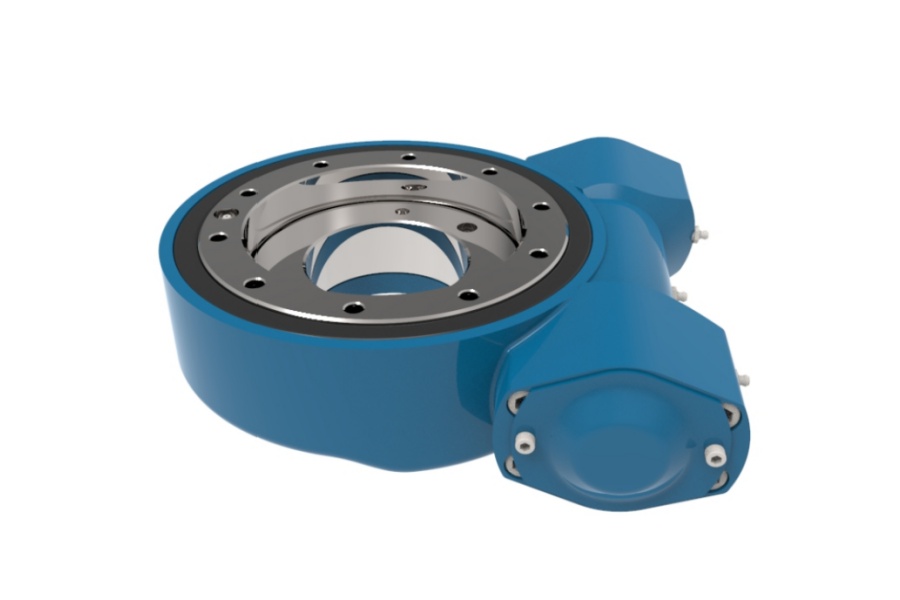

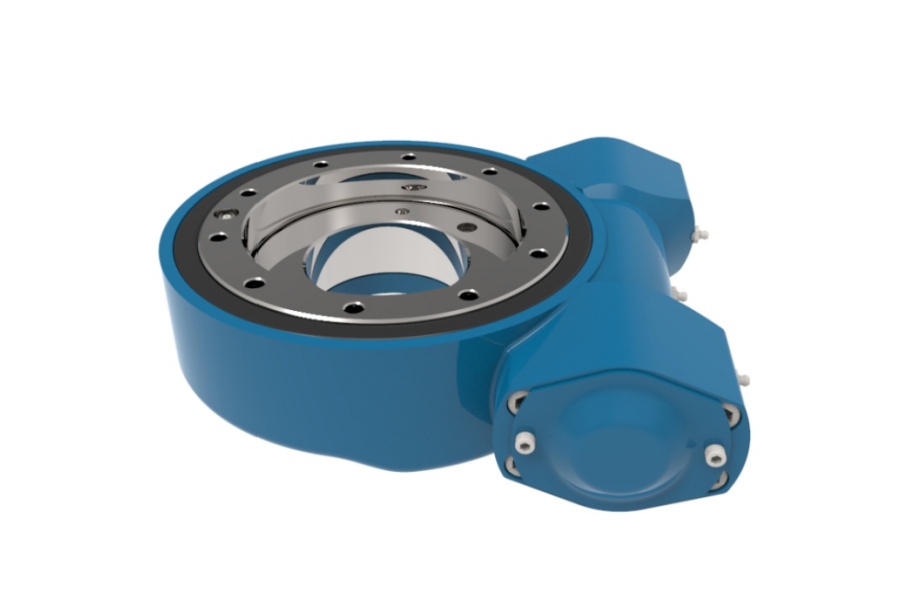

What is Worm Gear Slew Drive

Worm gear Slew drive utilizes a unique mechanism centered on a threaded screw (the worm) engaging with a specially designed gear (the worm wheel). The worm's helical threads mesh with the teeth on the periphery of the worm wheel. Crucially, the worm is typically positioned at 90 degrees to the axis of the worm wheel. When the worm rotates, it drives the worm wheel, resulting in Slew motion output. This configuration inherently provides a very high reduction ratio in a single stage due to the large difference in the number of threads on the worm versus the teeth on the worm wheel. A defining characteristic of the worm gear Slew drive is its irreversibility under most loads; the worm can easily turn the wheel, but the wheel cannot back-drive the worm due to the high friction angle inherent in the meshing action. This acts as a natural brake, holding the load securely without needing an additional braking system.

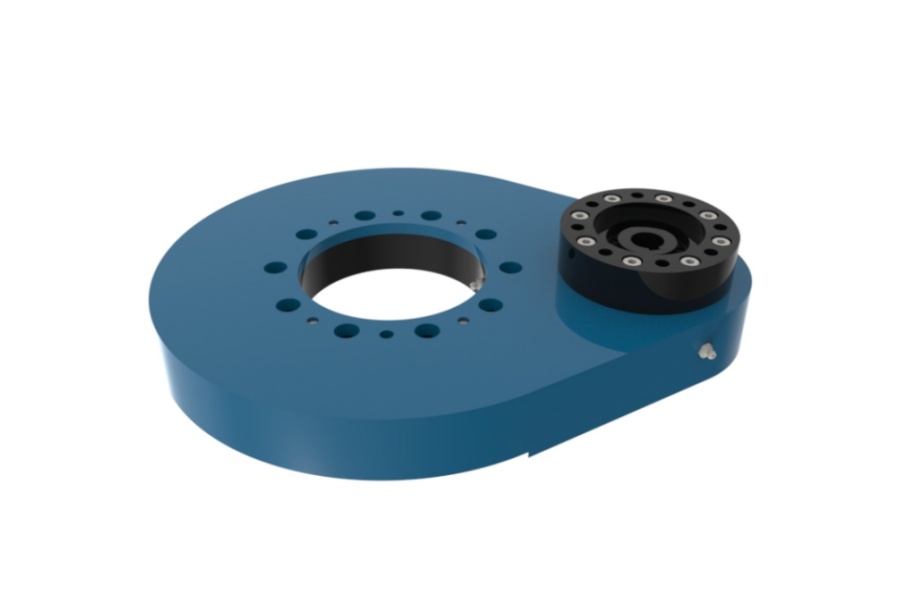

What is Spur Gear Slew Drive

Spur gear Slew drive operates on the principle of parallel axis gears meshing directly. It features two or more gears with straight teeth cut parallel to the axis of rotation. The primary driving gear (pinion) transmits motion and torque to the larger driven gear mounted on the output shaft. Unlike the worm drive, the rotational axes of the input and output shafts in a spur gear Slew drive are parallel. Spur gear drives are highly efficient in transmitting power, especially at lower reduction ratios, as the teeth engage with a rolling action that minimizes sliding friction compared to worm gears. They are generally reversible, meaning torque can be applied from either the input or output side, although backlash needs careful control. Spur gear drives excel in applications requiring high speed, high efficiency, and compact design for moderate torque levels.

Worm Gear and Spur Gear Slew Drive Differences

The differences between worm gear and spur gear Slew drives are significant and stem from their fundamental designs. The most notable distinction lies in their reversibility.

Worm gear drives are inherently non-backdrivable due to the high friction angle in the worm-worm wheel interface; the worm drives the wheel, but the wheel cannot drive the worm under typical loads, providing automatic braking.

Spur gear drives, conversely, are fully reversible; torque applied to the output shaft will rotate the input shaft. This makes worm drives ideal for holding positions securely without brakes, while spur drives require external brakes for similar holding capability.

Efficiency is another major difference. Spur gear drives are highly efficient, often exceeding 95% per stage, as power transmission primarily involves rolling contact. Worm gear drives suffer significantly higher energy losses due to substantial sliding friction between the worm threads and the worm wheel teeth; efficiencies often range between 50% and 90%, heavily dependent on the reduction ratio and lubrication, with higher ratios typically having lower efficiency.

Their tooth engagement differs drastically: worm drives feature a continuous line contact between the worm thread and worm wheel tooth, while spur gears engage with discrete points of contact along the tooth face. This impacts noise levels; well-manufactured spur gear drives operate relatively quietly, whereas worm drives can generate more noise, particularly at higher speeds or if not precisely manufactured. Finally, the shaft orientation is distinct: worm drives have perpendicular input and output shafts (90 degrees), while spur drives have parallel input and output shafts.

Worm Gear and Spur Gear Slew Drive Characteristics

Understanding the inherent characteristics of each drive type is crucial for selection.

Worm Gear Slew Drive Characteristics: The defining feature is high reduction ratio capability in a compact single stage, making them space-efficient for significant speed reduction. Their self-locking nature provides inherent braking and safety against back-driving, ideal for vertical lifts or holding static loads securely. They offer smooth and quiet operation at lower speeds, although noise can increase with speed. They generally exhibit good shock load resistance due to the enveloping nature of some worm wheel designs. However, they suffer from lower mechanical efficiency, leading to higher heat generation that requires careful thermal management and often necessitates larger housings or cooling fins. They also typically exhibit higher initial cost for comparable torque capacity due to more complex manufacturing.

Spur Gear Slew Drive Characteristics: These drives boast high mechanical efficiency, minimizing power loss and heat generation. They provide high precision and low backlash potential when manufactured with high tolerances and preloaded, crucial for positioning applications. They are capable of handling high input speeds, making them suitable for applications requiring faster rotation. Spur gear drives are generally more cost-effective for lower to medium reduction ratios and torque requirements. They generate less heat due to higher efficiency. However, they are not self-locking and require external brakes for load holding. Achieving high reduction ratios often requires multiple gear stages, increasing complexity and size compared to a single-stage worm drive. They can be noisier than helical or planetary gears, though often quieter than worm drives at comparable loads and speeds.

Worm Gear and Spur Gear Slew Drive Applications

The distinct characteristics of worm and spur gear Slew drives naturally lead them to different application domains.

Worm Gear Slew Drive Applications: Their self-locking and high-ratio strengths make them prevalent in solar tracking systems for precise panel positioning that must hold against wind loads. They are essential in material handling equipment like conveyors, lifts, and hoists where safety and load holding are paramount. Heavy-duty industrial machinery such as large valves, gates, and crushers benefit from their shock resistance and torque capacity. Medical and rehabilitation equipment often utilize them for safe and stable patient positioning. Packaging machinery and stage/entertainment rigging leverage their precise control and holding power.

Spur Gear Slew Drive Applications: Their efficiency and precision suit them well for robotics and automation arms/joints requiring accurate motion control and responsiveness. Machine tool accessories like Slew tables and indexers depend on their low backlash. Aerospace actuators (e.g., flap controls) value their reliability and efficiency. Precision instrumentation and optical positioning systems (telescopes, antennae) utilize their accuracy. Agricultural machinery components and food processing conveyors benefit from their robustness and efficiency. Smaller wind turbine yaw/pitch systems sometimes employ them for cost-effective control.

Factors Influencing Worm and Spur Gear Slew Drive Pricing

The price of both worm gear and spur gear Slew drives is influenced by several key factors.

Material Selection is paramount; high-strength alloy steels, specialized bronze for worm wheels, and advanced bearing steels significantly increase cost compared to standard carbon steels. Premium materials are essential for durability, corrosion resistance, and high-load capacity.

Manufacturing Precision and Complexity heavily impacts cost. Worm gear drives require extremely precise thread grinding on the worm and specialized hobbing/machining for the worm wheel to achieve correct tooth geometry and surface finish for efficient meshing. High-precision spur gears demand accurate hobbing, shaping, shaving, or grinding processes to ensure low noise, minimal backlash, and long life. Tighter tolerances exponentially increase manufacturing time and cost.

Size and Torque/Speed Rating directly correlate with price. Larger drives handling higher torque loads require more material, larger bearings, and often more complex heat management solutions. Drives rated for very high input speeds need superior balancing and bearing specifications.

Integrated Components add cost. Drives supplied with high-precision bearings (e.g., crossed rollers), high-efficiency seals, integrated motors (hollow shaft or flange-mounted), brakes, encoders, or feedback sensors increase the overall unit price significantly compared to a bare drive unit.

Sealing and Protection Level (IP rating) affects cost. Achieving high ingress protection (e.g., IP65, IP67) against dust and water requires sophisticated sealing designs and materials, particularly challenging for Slew interfaces.

Lubrication System complexity matters. Standard grease lubrication is cost-effective, but drives requiring forced oil circulation, cooling systems, or specialized high-temperature lubricants add expense.

Volume and Customization play a role. Standard catalog drives benefit from economies of scale. Highly customized drives (special mounting flanges, shafts, unusual ratios, specific materials) incur significant engineering and setup costs, making them more expensive per unit.

Quality Control and Testing standards influence price. Drives subjected to rigorous in-process inspection, final testing (efficiency, backlash, noise, life testing), and certified to specific standards (ISO, AGMA) command higher prices due to the resources invested in ensuring reliability and performance.

Worm Gear and Spur Gear Slew Drive Supplier

LYRADRIVE stands as a prominent manufacturer and supplier of high-performance Slew drive solutions, offering both precision worm gear and spur gear Slew drive configurations. They leverage advanced engineering capabilities and rigorous manufacturing processes to produce drives known for reliability, durability, and precise motion control. LYRADRIVE caters to diverse industrial sectors, providing standard catalog products alongside customized solutions tailored to specific application requirements for torque, speed, size, sealing, and environmental conditions. Their focus on quality control ensures consistent performance for demanding applications in automation, renewable energy, material handling, and specialized machinery.