How to Calculate Slewing Bearing Friction

What is Slewing Bearing

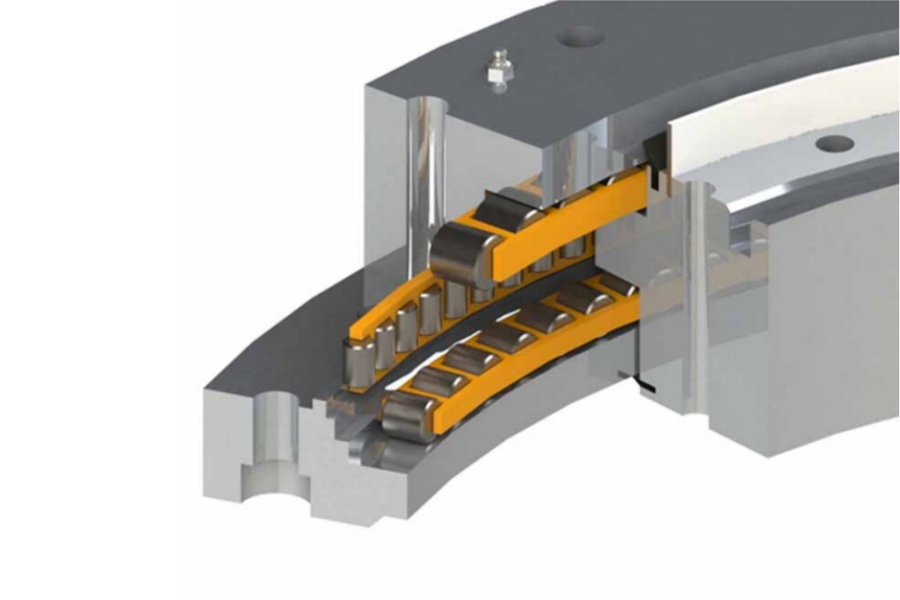

Slewing bearing is a large-diameter rotational bearing engineered to handle combined axial, radial, and moment loads simultaneously. It features robust inner and outer rings with rolling elements (balls or rollers) and often includes integrated gear teeth. Serving as the pivotal rotation point in heavy machinery like cranes, excavators, and wind turbines, it provides structural support and smooth rotational motion under extreme loads.

How to Calculate Slewing Bearing Friction

Calculating slewing bearing friction torque involves understanding two primary friction states:

Static Friction (Start-up):

This is the friction that must be overcome to initiate rotation from a standstill. Static friction is highly variable and cannot be calculated by a simple universal formula. It depends on factors like:

Surface adhesion between rolling elements and raceways

Condition of the lubricant film after prolonged rest

Settling of components under load

Seal drag at zero speed

Manufacturers typically provide empirical values for starting torque based on bearing size, load, and seal type. If specific data is unavailable, a conservative estimate is often 1.5 to 3 times the calculated running friction torque.

Sliding/Rolling Friction (Running):

This is the friction during continuous rotation. A simplified approach estimates the total friction torque using the formula:

Friction Torque = Friction Coefficient * Equivalent Load * (Bearing Pitch Diameter / 2)

Friction Coefficient (μ): This is not a single fixed number. It depends on bearing type (ball, roller), lubrication quality, speed, load, and especially seal drag. Typical values range from 0.004 to 0.02 for the rolling friction itself, but seals can dominate, pushing the effective total coefficient much higher (0.05 to 0.15 or more).

Equivalent Load: Represents the combined effect of the actual axial, radial, and moment loads acting on the bearing. Manufacturers provide specific formulas based on bearing geometry to calculate this equivalent load (P or F_equiv).

Bearing Pitch Diameter (d_m): The diameter where the rolling elements make contact, roughly the average of the inner and outer ring diameters. Divide by 2 to get the friction arm.

Seal Friction: This is often the largest contributor. Its drag torque depends on seal design, material, lip pressure, and shaft diameter. Manufacturer data is essential for accurate estimation.

Lubricant Drag: At higher speeds, viscous drag within the lubricant adds to friction.

Key Points for Calculation:

Start-up vs Running: Always distinguish between the higher static friction (for motor sizing) and lower running friction (for power/heat calculations).

Seals are Critical: Never neglect seal friction; it frequently dominates total torque.

Manufacturer Data is Key: Reliable calculation requires specific friction coefficients, seal drag values, and equivalent load formulas provided by the slewing bearing manufacturer for their specific product and operating conditions (load, speed, lubrication). Generic formulas offer only rough estimates.

Lubrication Matters: Proper lubrication significantly reduces friction coefficients.

Slewing Bearing Characteristics

Slewing bearings are defined by their unique capabilities:

Combined Load Handling: Excel at managing heavy axial, radial, and tilting moment loads simultaneously.

Integrated Design: Often feature machined gear teeth on one ring for direct drive connection.

Compact Structure: Provide a complete rotation solution within a single, space-saving unit.

High Rigidity: Engineered for minimal deflection under load, ensuring precision and stability.

Customization: Available in diverse sizes, rolling element types, gear options, and sealing arrangements.

Durability: Built to withstand harsh environments, shock loads, and continuous operation.

Slewing Bearing Applications

Slewing bearings are vital rotation points across numerous industries:

Construction Machinery: Excavators, cranes, concrete pump booms.

Material Handling: Stackers, reclaimers, port cranes, forklifts.

Wind Energy: Yaw drives (nacelle rotation) and pitch drives (blade angle adjustment).

Solar Energy: Solar tracker azimuth and elevation drives.

Industrial Automation: Robotic welders, heavy-duty turntables, indexing tables.

Defense & Aerospace: Radar platforms, missile launchers, telescope mounts.

Mining & Aggregate: Crushers, screens, bucket wheels.

Medical: Heavy-duty imaging equipment (CT, MRI) rotation.

Factors Influencing Slewing Bearing Price

The cost of a slewing bearing is driven by multiple factors:

Size and Load Capacity: Larger bearings handling higher loads require significantly more material and complex manufacturing, increasing cost exponentially.

Bearing Type and Design: Crossed roller bearings are typically more expensive than four-point contact ball bearings or single-row ball designs for similar capacities. Custom designs cost more than standard catalog items.

Material Grade: High-strength, case-hardened alloy steels are standard. Special materials (e.g., corrosion-resistant steels) add cost.

Manufacturing Precision: Tight tolerances for gear teeth, raceways, and mounting surfaces require advanced machining/grinding, increasing production time and cost.

Gear Teeth: Inclusion of gear teeth (helical usually more than spur), their size, quality class, and whether they are internal or external significantly impact price.

Sealing System: High-performance seals (multiple lips, specific elastomers) for harsh environments (IP67/69K, high pressure washdown) are costly.

Rolling Elements: Type (balls, rollers), size, quantity, and precision grade affect cost.

Lubrication System: Integrated automatic lubrication systems add expense.

Heat Treatment: Sophisticated case hardening and tempering processes are essential for durability but add cost.

Quality Control & Certification: Rigorous testing (NDT, load testing, gear inspection) and certifications (ISO, DNV-GL) add to the price.

Quantity: Economies of scale apply; unit cost decreases with larger order volumes.

Supplier of Slewing Bearing

LYRADRIVE is a recognized manufacturer and supplier of high-quality slewing bearings engineered for demanding applications. They offer a comprehensive range of standard designs alongside tailored solutions, focusing on robust construction, precise engineering, and reliable performance. LYRADRIVE serves diverse sectors including renewable energy, construction, material handling, and industrial automation, providing bearings known for durability under significant combined loads and challenging operating conditions.