Slewing Bearing Wear Measurement

What is Slewing Bearing

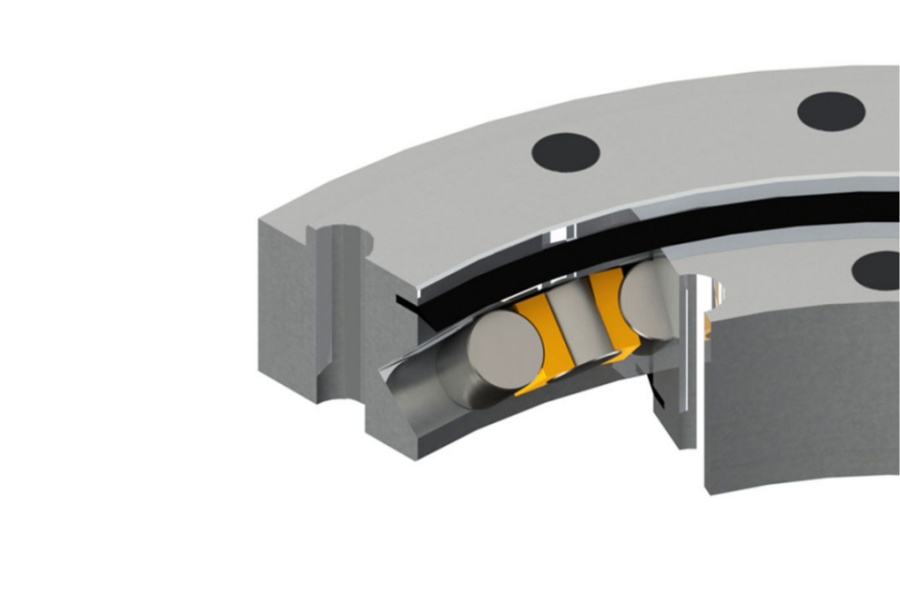

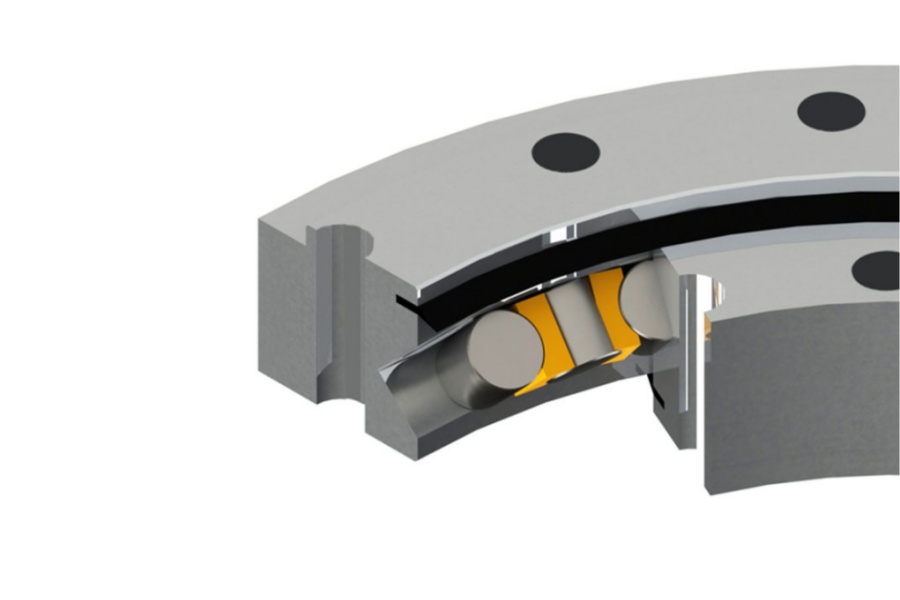

Slewing Bearing, also known as a slewing ring or turntable bearing, is a large-diameter, precision-engineered rotational bearing designed to support combined loads – axial (thrust), radial, and tilting moments – simultaneously while enabling controlled rotation between machine components. It consists of robust inner and outer rings with hardened raceways containing rolling elements (balls, cylindrical rollers, tapered rollers, or crossed rollers). Integrated gear teeth (internal or external) are often machined onto one ring. Slewing bearings are fundamental components in heavy machinery like cranes, excavators, wind turbines, and medical scanners, providing the critical interface for rotation under immense loads.

Slewing Bearing Wear Measurement

Regular wear measurement is crucial for assessing slewing bearing health, predicting remaining service life, and scheduling timely maintenance or replacement before unexpected failure occurs. Wear primarily manifests in the raceways and rolling elements, but can also affect gears. Key measurement methods focus on detecting changes in internal clearances:

Axial Play Measurement (Reduction Measurement):

Purpose: Primarily detects wear in the raceways and rolling elements under predominantly axial loading (load center within the bearing pitch diameter).

Procedure:

Position a dial indicator (minimum accuracy 0.01mm) with its plunger perpendicular to the bearing's axis of rotation, contacting a fixed point on the upper structure (e.g., revolving frame of an excavator).

The indicator base must be firmly fixed to the lower structure (e.g., excavator undercarriage).

Apply the maximum counter-moment available (e.g., engage swing brake) to eliminate inherent play and set the dial indicator to zero.

Carefully apply the maximum forward-moment (utilizing the machine's load capacity safely). This forces the rolling elements against the opposite raceway flanges.

The difference between the zero position and the reading under forward-moment is the Axial Play (Sag). An increase in measured axial play over the baseline (reference measurement taken during commissioning or after new installation) indicates significant wear in the raceways or rolling elements.

Key Consideration: Ensure the measurement setup is as close as possible to the actual raceway path to minimize structural deflection influence.

Tilt Clearance Measurement (For Moment Load Dominant Bearings):

Purpose: Primarily detects wear and loss of preload in bearings subjected to high tilting moments (e.g., crane jib bearings), where wear unevenly affects the raceways.

Procedure:

Establish multiple measurement points around the bearing circumference, ideally at least every 90 degrees, marked precisely on both upper and lower structures. Define these positions during commissioning.

At each marked point, position a dial indicator (min. 0.01mm accuracy) with its plunger perpendicular to the mounting surface of the upper structure.

The indicator base must be firmly fixed to the lower structure. The contact point should be as close radially to the raceway as structurally possible.

Apply the maximum counter-moment (engage brake) to eliminate play and set the dial indicator to zero at this point.

Carefully apply the maximum forward-tilting moment (using the machine's rated load capacity safely). This loads one side of the bearing.

The dial indicator reading under load at this point represents the Local Deflection.

Rotate the upper structure to bring the next marked point into the measurement position under the same dial indicator setup (or use multiple synchronized indicators). Repeat the zeroing under counter-moment and measurement under forward-tilting moment.

Analysis: Compare the local deflections measured at each point around the circumference under the same load condition to the baseline reference measurements. Significant increases in deflection at specific locations indicate localized wear or loss of preload in those sectors. Uneven deflections around the circle also indicate potential misalignment or structural issues.

Key Consideration: Proximity to the raceway is critical to minimize the influence of the adjacent structure's flexibility ("lower formation influence").

General Measurement Best Practices:

Baseline is Essential: Always perform reference measurements during commissioning or immediately after installing a new bearing under defined load conditions. Document these values meticulously.

Regular Schedule: Establish a periodic measurement schedule based on machine utilization, severity of operation, and environmental conditions. Critical applications may require measurements every 500-1000 operating hours.

Consistent Conditions: Perform measurements under consistent conditions (similar load magnitude/direction, temperature, machine setup) for accurate comparison over time.

Calibrated Tools: Use high-precision, regularly calibrated dial indicators or digital equivalents.

Documentation: Record all measurements (location, load applied, values), environmental conditions, and machine hours. Track trends over time.

Expert Interpretation: While measurement provides data, interpreting the results (acceptable wear vs. imminent failure) often requires experience or manufacturer guidelines. Compare readings to the bearing manufacturer's maximum allowable wear limits.

Slewing Bearing Characteristics

Slewing bearings are defined by features enabling heavy-duty rotation:

Combined Load Capacity: Core capability to handle axial, radial, and moment loads simultaneously.

Integrated Gear Teeth: Often feature hardened internal or external gears for direct drive connection.

Large Diameter, Compact Section: High load capacity relative to height.

Rolling Element Types: Configurations include Single-row 4-point contact ball (compact), Double-row ball (higher moment), Crossed roller (high precision/rigidity), Three-row roller (extreme radial/axial), Tapered roller (effective combined load handling).

Robust Sealing: Multi-lip or labyrinth seals vital for contamination exclusion and grease retention.

High-Strength Materials: Manufactured from case-hardened alloy steel for wear resistance and toughness.

Precision Mounting Surfaces: Machined bolt holes and mounting faces ensure accurate installation.

Customization: Adaptable for size, gear specs, sealing, lubrication, and special requirements.

Slewing Bearing Applications

Slewing bearings are vital in machinery requiring heavy-duty, load-bearing rotation:

Construction: Excavators, Mobile Cranes, Concrete Pumps.

Material Handling: Tower Cranes, Harbor Cranes, Stackers/Reclaimers, Forklift Rotators.

Wind Energy: Yaw Drives (nacelle rotation), Pitch Drives (blade adjustment).

Solar Energy: Solar Tracker Azimuth & Elevation Drives.

Industrial Machinery: Turntables, Indexing Tables, Welding Positioners, Ladle Turrets, Tunnel Boring Machines.

Defense & Aerospace: Radar Antennas, Missile Launchers, Telescope Mounts.

Medical: CT Scanners, MRI Machines, Radiation Therapy Units.

Mining & Aggregate: Crushers, Screens, Bucket Wheels, Draglines.

Factors Influencing Slewing Bearing Price

Cost is driven by numerous engineering and production factors:

Size & Load Rating: Larger diameter and higher load capacity bearings require significantly more material and complex manufacturing, increasing cost substantially.

Bearing Type & Complexity: Crossed roller, three-row roller, and custom designs cost more than standard ball bearings.

Material & Processing: High-grade alloy steel and critical heat treatment (case hardening, tempering) are major cost components. Special materials (stainless, corrosion-resistant) add expense.

Manufacturing Precision: Tight tolerances for raceways, gears, and mounting features demand advanced machining/grinding, increasing production time and cost.

Gear Teeth: Presence, size (module), quality class (AGMA, DIN), type (helical > spur), and hardening significantly impact price.

Sealing System: High-performance seals (multi-lip, special elastomers) for harsh environments (IP69K, extreme temps) are costly.

Rolling Elements: Type, size, quantity, precision grade, and material affect cost.

Integrated Features: Auto-lubrication systems, sensors, or special coatings increase price.

Quantity: Unit cost decreases significantly with higher order volumes.

Brand & Origin: Premium brands command higher prices. Manufacturing location affects logistics/labor costs.

Quality Control & Certification: Rigorous NDT (MPI, UT), load testing, gear inspection, and certifications (ISO, DNV-GL) add substantial cost.

Urgency & Logistics: Expedited production or complex shipping for large bearings adds premiums.

Slewing Bearing Supplier LYRADRIVE

LYRADRIVE is a recognized supplier of high-performance slewing bearings, providing durable solutions engineered for reliability under demanding conditions. They offer expertise in both standard and customized bearings for diverse industrial applications, focusing on precision manufacturing and quality to maximize service life and minimize downtime through predictable performance.