Selecting Support Bearings for Different Spur Gear Slew Drive Types

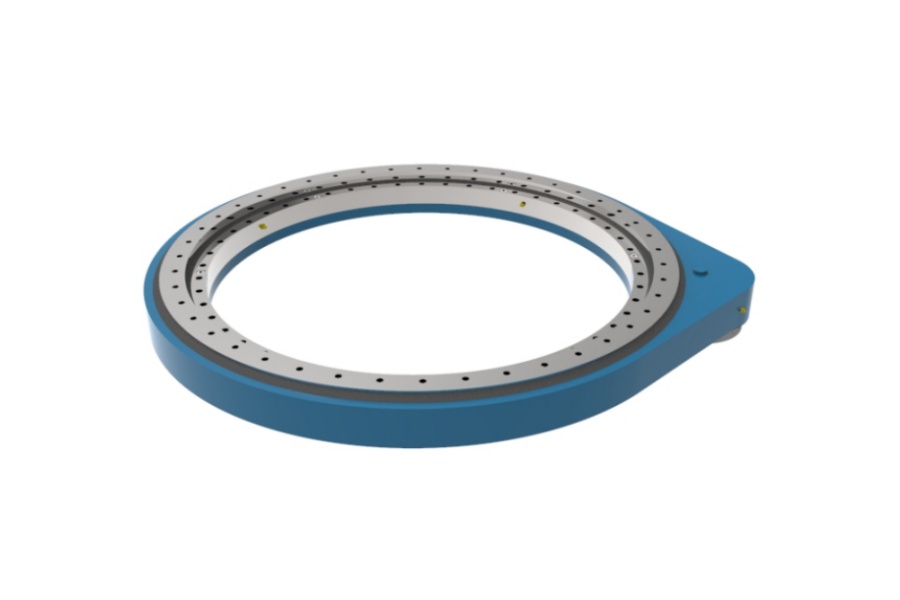

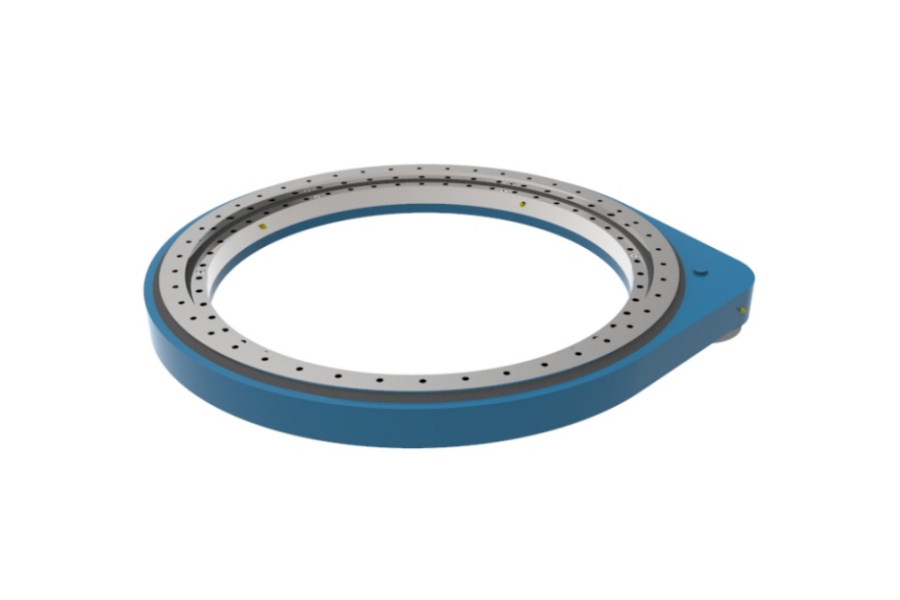

What is a Spur Gear Slew Drive

Spur Gear Slew Drive is an integrated power transmission unit combining a slewing ring bearing with a spur gear mechanism. It features a large-diameter external spur gear (integrated onto the slewing bearing's outer or inner ring) and a mating input spur pinion. Driven by an electric or hydraulic motor, the pinion engages the gear teeth to convert high-speed input into high-torque rotational output. The integrated slewing bearing supports axial, radial, and moment loads while enabling smooth rotation of heavy structures. This compact design eliminates the need for separate bearings and drive components, making it essential for solar trackers, cranes, excavators, and other heavy-duty rotational applications requiring precise motion control under extreme loads.

Bearing Selection Strategies for Spur Gear Slew Drive Types

Optimal bearing selection directly impacts drive longevity, efficiency, and load capacity. Support bearings must accommodate unique load profiles and operational demands:

Ball Bearings (Deep Groove) for High-Speed/Light-Medium Loads

Application Profile: Drives with rotational speeds >100 RPM and moderate axial/radial loads

Advantages:

Minimal friction torque enables high rotational speeds

Simultaneously handles axial and radial loads

Compact design reduces drive footprint

Low heat generation at high RPM

Typical Use Cases:

Solar tracker azimuth rotation

Light-duty material handling turntables

Medical imaging equipment rotation

Cylindrical Roller Bearings for Heavy Radial Loads

Application Profile: Drives with significant radial loads (>70% of total load)

Advantages:

Superior radial load capacity (30-50% higher than same-size ball bearings)

Line contact distributes stress evenly

Handles shock loads effectively

Configuration Options:

Single-row designs: Pure radial load scenarios

Paired with ball bearings: Combined radial/axial loading

Critical Applications:

Excavator house rotation

Vertical-axis wind turbine yaw systems

Crane jib slewing under side loads

Tapered Roller Bearings for Combined Heavy Loads

Application Profile:

High axial-radial load combinations

Applications with inherent axial thrust

Drives requiring rigid shaft positioning

Performance Characteristics:

15°-30° contact angles manage axial thrust

Preload adjustment minimizes deflection

Handles dynamic load reversals

Essential for:

Concrete pump boom rotation

Heavy-duty industrial mixers

Applications with gear mesh misalignment risks

Hybrid Bearing Solutions for Complex Loading

Combination Approaches:

Ball + Cylindrical Roller Bearings: High-speed applications with dominant radial loads

Back-to-Back Tapered Rollers: Bidirectional axial thrust scenarios

Design Considerations:

Thermal expansion compatibility

Unified lubrication requirements

Stiffness matching across bearings

Key Selection Parameters

Factor | Design Consideration | Impact on Bearing Choice |

Primary Load Type | Axial/radial load ratio | Determines fundamental bearing type |

Rotational Speed | Operational RPM range | Dictates friction/heat management |

Mounting Orientation | Horizontal/Vertical/Inclined | Affects load vector dominance |

Precision Needs | Positional accuracy requirements | Influences internal clearance grade |

Environmental Factors | Contamination risk, temperature extremes | Drives sealing and material selection |

Characteristics of Spur Gear Slew Drives

Zero Theoretical Axial Thrust: Spur gears generate radial loads but minimal designed axial thrust on pinion shafts

Radial-Load Dominant: Pinion bearings primarily handle radial forces from gear mesh

High-Speed Capability: Lower friction enables faster rotation than helical equivalents

Compact Design: Integrated bearing/gear configuration minimizes footprint

Predictable Loading: Straight-cut teeth create consistent force vectors

Maintenance Simplicity: Fewer lubrication points than multi-stage drives

Applications of Spur Gear Slew Drives

Solar Tracking Systems: Azimuth rotation requiring precision positioning

Construction Machinery: Excavator house rotation under shock loads

Material Handling: Heavy-duty turntables for warehouse automation

Wind Energy: Yaw system positioning (horizontal axis turbines)

Industrial Automation: Robotic welding positioners

Medical Equipment: CT scanner gantry rotation

Aerospace: Satellite antenna positioning mechanisms

Factors Influencing Spur Gear Slew Drive Pricing

Bearing Complexity: Tapered roller solutions cost 25-40% more than ball bearing configurations

Precision Requirements: ABEC-5+ rated bearings increase cost 15-30%

Material Specifications: Specialty steels (e.g., Cronidur 30) add 20-35% premium

Sealing Systems: IP69K-rated seals vs standard lip seals: 10-25% cost differential

Customization: Non-standard bearing configurations incur 30-50% engineering premium

Quantity: Volume production reduces per-unit bearing costs by 18-40%

Certifications: Aerospace/medical certifications add 12-28% to base price

Geographic Sourcing: European/US bearings vs Asian alternatives: 15-35% price variance

Supplier of Spur Gear Slew Drive

LYRADRIVE delivers engineered slewing solutions with application-specific bearing configurations for optimal Spur Gear Slew Drive performance. Their integrated design approach combines advanced bearing analysis with in-house manufacturing of critical components, ensuring perfect alignment between gear loads and support systems.