SE21 Enveloping Rotary Drive: The Silent Powerhouse Revolutionizing Heavy-Duty Motion

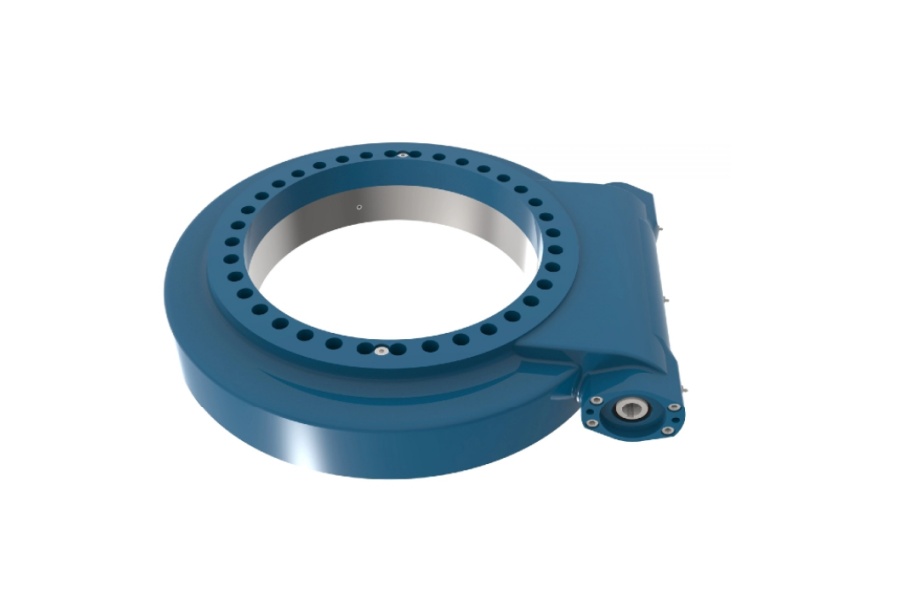

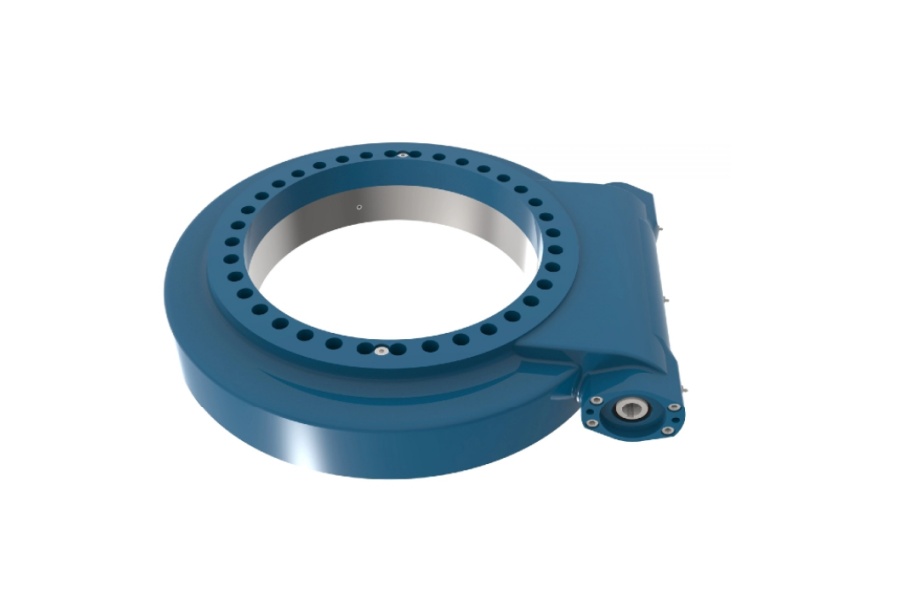

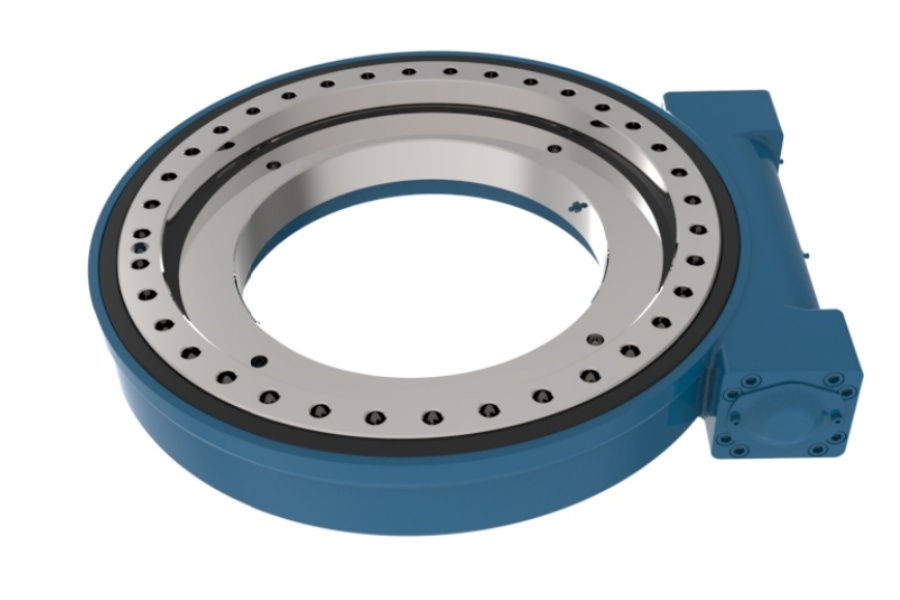

What is the Enveloping Rotary Drive SE21?

The SE21 Enveloping Rotary Drive represents a paradigm shift in power transmission. Its core innovation lies in the "enveloping" principle. Unlike standard gears with limited tooth contact, the SE21 features a unique worm and wheel design where the worm threads wrap significantly around the circumference of the wheel. This dramatically increases the number of teeth engaged simultaneously under load. The result? Exceptional torque density – immense power transmitted from a remarkably compact and rigid package. The SE21 delivers smooth, virtually silent operation with minimal backlash, superior shock load absorption, and an inherent self-locking capability (depending on the lead angle), making it ideal for critical positioning and holding applications. Its robust, integrated housing design eliminates misalignment issues common in traditional setups, ensuring longevity and consistent performance under punishing conditions.

Conquering the Depths: SE21 Drives in Tunnel Boring Machines (TBMs)

Tunnel Boring Machines operate in the harshest imaginable environment: extreme pressures, abrasive muck, relentless vibration, and zero tolerance for failure. The SE21 Enveloping Rotary Drive excels here as the core component driving the cutterhead's rotation. Its compact size is crucial within the TBM's confined space constraints. The immense torque density allows powerful cutting forces to be generated efficiently, driving the massive cutterhead through rock and soil. Crucially, the enveloping design provides unmatched rigidity and load distribution. This ensures precise cutterhead positioning and control, vital for maintaining tunnel alignment and profile accuracy over kilometers. The drive's ability to handle severe shock loads from varying ground conditions and its exceptional durability significantly reduce downtime and maintenance costs, directly impacting project timelines and budgets. The SE21 is engineered to be the reliable muscle behind every revolution underground.

Safety First: Explosion-Proof Enveloping Rotary Drive SE21

Hazardous environments like oil and gas platforms, chemical plants, mining operations, and grain handling facilities demand equipment that cannot ignite flammable atmospheres. The Explosion-Proof variant of the SE21 Enveloping Rotary Drive is meticulously engineered to meet stringent global standards (ATEX, IECEx, UL, etc.). This involves specialized construction techniques: flameproof or pressurized enclosures to contain any potential internal ignition, non-sparking materials for critical components, strict temperature control to prevent surface temperatures exceeding the auto-ignition point of specific gases or dusts, and enhanced sealing to prevent ingress of hazardous substances. Every aspect, from casting design and bearing selection to lubrication systems and surface finishes, is scrutinized and certified. The result is a drive that delivers the signature SE21 performance – high torque, compactness, precision – without compromising safety in Zone 1, Zone 2, or Division 1/Division 2 classified areas, protecting personnel and infrastructure.

Mastering the Cold: SE21 Low-Temperature Operation Guide

Arctic operations, cryogenic processing, and winterized outdoor equipment require drives that function reliably well below freezing. Selecting and configuring an SE21 Enveloping Rotary Drive for low-temperature service (-20°C / -4°F and far beyond) demands specific considerations. Lubrication is Paramount: Standard greases solidify. Special synthetic lubricants formulated for extreme cold, with drastically lower pour points and maintained viscosity, are essential. Consult LYRADRIVE's lubrication charts for the specific temperature range. Material Selection Matters: Standard seals become brittle. Viton or specialized cold-rated elastomers ensure sealing integrity. Steel grades and treatments must account for potential embrittlement at ultra-low temperatures. Pre-Operation Conditioning: In severe cold starts, allowing the drive and lubricant to warm gradually (if possible) or using trace heating minimizes stress. Reduced Power Factor: Be aware that bearing friction and lubricant drag increase initially at very low temps; systems might require slightly derated starting torque temporarily. Condensation Control: Proper breathers or desiccant systems prevent internal moisture ingress, which can freeze. Clearly specifying the minimum expected operating temperature is critical for LYRADRIVE to configure your SE21 for flawless cold-weather performance.

Unmatched Capabilities: Key Features of the SE21 Enveloping Rotary Drive

The SE21 isn't just different; it's demonstrably superior in key areas critical for industrial performance. Exceptional Torque Density: Its enveloping design generates up to 3 times the torque of similarly sized conventional gear reducers, enabling smaller, lighter machinery designs. Superior Rigidity & Precision: The large contact area and robust housing deliver minimal torsional deflection and extremely low backlash, crucial for accurate positioning and repeatability. Smooth & Silent Operation: Multiple tooth engagement ensures quiet power transmission, reducing noise pollution in sensitive environments. Inherent Shock Load Capacity: The enveloping action naturally distributes impact loads across many teeth, protecting the drive and connected components. Self-Locking Capability (Optional): Specific ratios offer a natural braking force, holding loads securely without needing an external brake in many applications. High Efficiency: Optimized gear geometry minimizes power loss, saving energy. Integrated Design: The compact, single-unit housing simplifies mounting, reduces points of failure, and enhances overall system stiffness. Unrivaled Durability: Precision manufacturing and premium materials ensure long service life even under continuous heavy loads. Versatility: Available in various sizes, ratios, mounting configurations, and with numerous customization options (shafts, flanges, seals, coatings).

Powering Industry: Diverse Applications of the SE21 Drive

The unique combination of power, precision, and compactness makes the SE21 Enveloping Rotary Drive indispensable across countless sectors. Heavy Machinery: It's the heart of slewing rings in cranes (mobile, tower, offshore), excavators, and heavy-duty positioning systems, handling massive loads with precision. Material Handling: Revolutionizes rotary actuators for heavy-duty valves, robust index tables, palletizers, and conveyor diverters demanding high torque in tight spaces. Construction & Mining: Essential for TBMs, drilling rigs (rotary tables, pipe handling), conveyor drives, and heavy-duty screen vibrators. Robotics & Automation: Provides precise, high-torque motion for welding arms, heavy payload handling robots, and automated assembly systems needing rigidity and accuracy. Renewable Energy: Powers solar tracker azimuth drives and pitch/yaw mechanisms in wind turbines, enduring harsh weather and high loads. Defense & Aerospace: Used in radar positioning, missile launcher traversal/elevation, and ground support equipment requiring reliability and precision. Specialized Manufacturing: Drives rotary furnaces, mixers, and positioning stages in steel, glass, and chemical processing. Hazardous Environments: The explosion-proof variant is critical for safety in oil & gas, chemical plants, and grain elevators.

Understanding Investment: Factors Influencing SE21 Drive Pricing

The SE21 Enveloping Rotary Drive is a premium engineered component, and its price reflects its advanced design, performance, and build quality. Several key factors determine the final cost: Size & Torque Rating: Larger drives designed for higher torque capacities naturally command higher prices due to more material and complex manufacturing. Gear Ratio: Specific ratios, especially very high reduction ratios, can impact complexity and cost. Configuration: Input options (solid shaft, hollow shaft, flange mount, specific motor adapter), output flange types, and mounting provisions influence machining and assembly costs. Material Specifications: Standard cast iron is common, but requests for special alloys (e.g., for corrosion resistance, low-temperature use) or hardened components increase cost. Customization: Extensive modifications beyond standard offerings (special shaft dimensions, unique bolt patterns, integrated sensors, special coatings/paint) add engineering and manufacturing expense. Sealing & Protection: Standard seals suffice for many, but high-pressure seals, specialized labyrinth seals, or IP69K-rated protection for severe washdowns add cost. Explosion-Proof Certification: Meeting ATEX/IECEx/UL standards requires rigorous design, testing, documentation, and certified components, significantly increasing the price compared to a standard unit. Order Volume: Larger production runs typically benefit from economies of scale, reducing the per-unit cost. Bearings & Internal Components: Higher precision classes or specialized bearings (e.g., for ultra-high rigidity or extreme temperatures) affect price.

Supplier of SE21 Enveloping Rotary Drive

When performance, reliability, and innovation in rotary motion are non-negotiable, LYRADRIVE stands as the premier global supplier and engineering authority behind the SE21 Enveloping Rotary Drive. More than just a manufacturer, LYRADRIVE possesses deep application expertise, collaborating closely with customers to tailor SE21 solutions for the most challenging requirements. Their commitment is evident in rigorous quality control throughout the manufacturing process, utilizing state-of-the-art facilities and premium materials to ensure every drive meets the highest standards. LYRADRIVE offers comprehensive technical support, from initial concept and selection guidance through detailed application engineering, customization, installation support, and after-sales service. They maintain extensive global distribution and service networks, ensuring timely delivery and local support wherever your operations are located. Choosing LYRADRIVE means partnering with the innovators who perfected enveloping technology, guaranteeing access to genuine SE21 drives backed by unparalleled engineering knowledge and a commitment to your application's success. Contact LYRADRIVE to experience the ultimate in compact, high-torque rotary power.