Revolutionizing Motion: The Featherweight Powerhouse Transforming Precision Industries

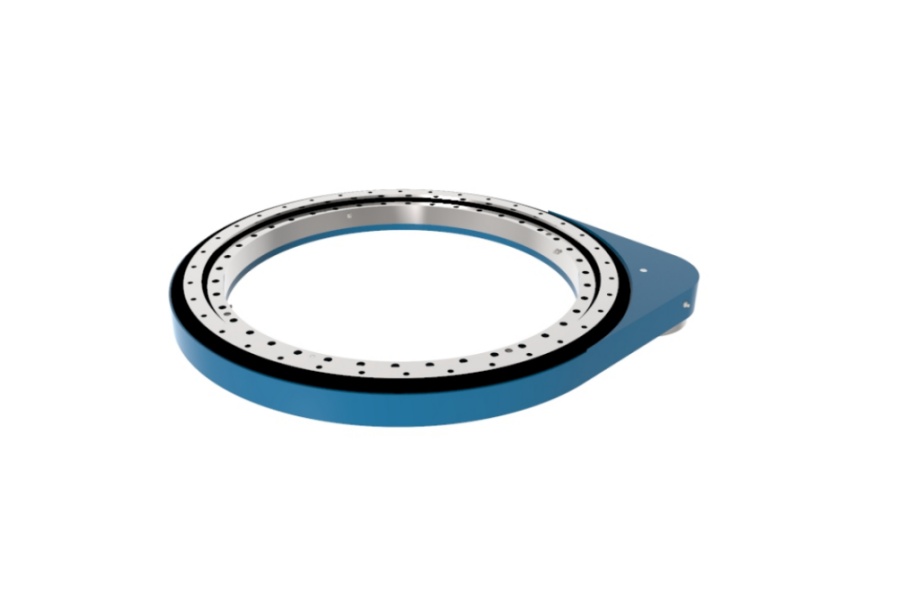

What is the Lightweight Slewing Ring Gear Drive SP-I 0741?

The SP-I 0741 represents a paradigm shift in slewing drive technology. Unlike traditional bulky rotational drives, it integrates a high-strength alloy slewing ring with a precision planetary gearbox into a singular, optimized unit. Its monobloc housing eliminates redundant structural components, achieving remarkable weight reduction without sacrificing torsional rigidity or load capacity. Engineered for applications demanding extreme weight consciousness—like drone gimbals and satellite mechanisms—it delivers torque densities exceeding 150 Nm/kg. The hardened gear teeth undergo superfinishing, ensuring near-silent operation (<55 dB) and minimal vibration, critical for sensitive payloads.

Mastering Precision: SP-I 0741 Backlash Adjustment

Precision motion hinges on eliminating unwanted play. The SP-I 0741 incorporates a proprietary radial preload system for backlash adjustment, accessible via external adjustment screws without drive disassembly. This allows field technicians to maintain micron-level gear mesh accuracy (adjustable down to ≤1 arc-min) throughout the drive’s operational lifecycle. The system utilizes Belleville washers maintaining constant preload force despite thermal expansion or wear. This eliminates the "dead zone" in positioning applications, crucial for laser targeting systems or robotic arms requiring repeatable ±0.01° accuracy. Regular backlash adjustment ensures sustained performance, especially in dynamic loading environments.

Why Low Profile Design is a Game-Changer

The SP-I 0741’s low profile slewing drive architecture (axial height under 32mm for the 0741 model) solves critical spatial constraints. Traditional drives often require significant Z-axis space, complicating integration in compact systems. This slim design enables direct mounting in tight chassis—like surgical robot joints or UAV pan-tilt units—freeing up valuable real estate for other components or payloads. The reduced center of gravity also enhances stability in mobile platforms, minimizing tilt-induced errors. By eliminating the need for bulky mounting adapters, the low profile further contributes to overall system weight reduction and structural simplicity.

Drone Gimbal Servo Weight Reduction Breakthrough

Drone performance lives and dies by weight. Heavy gimbal servos drain battery life, reduce agility, and limit payload capacity. The SP-I 0741 directly addresses drone gimbal servo weight reduction, replacing conventional motor-gearbox combinations with a unified drive up to 60% lighter. Its direct-drive capability eliminates intermediary couplings and mounting hardware. With a continuous torque rating of 41 Nm yet weighing under 1.1kg, it enables longer flight times and smoother stabilization for high-resolution cinematography or LiDAR surveying. The drive’s high rigidity (<0.05 arc-min torsion under load) ensures jitter-free imagery even in turbulent conditions, a critical advantage for professional aerial platforms.

Unleashing Innovation: Key Features of the SP-I 0741

Radical Weight Savings: Advanced aluminum alloys and topology-optimized structures achieve unmatched power-to-weight ratios.

Integrated Sealing: IP67-rated seals protect against dust, moisture, and chemical ingress in harsh environments.

High-Efficiency Gearing: >92% mechanical efficiency minimizes heat generation and energy loss.

Ultra-Low Backlash: Maintains ≤1 arc-min backlash even after thousands of operational hours.

Corrosion Resistance: Hard-anodized surfaces and stainless steel fasteners ensure longevity in marine or outdoor settings.

Modular Input Options: Compatible with standard servo motors, steppers, or hydraulic motors via adaptable input flanges.

Embedded Sensor Readiness: Pre-machined ports for encoders or torque sensors enable closed-loop control.

Where Featherweight Power Transforms Industries

The SP-I 0741’s unique capabilities enable next-generation applications:

Aerospace & Drones: Gimbal stabilization, antenna positioning, and lightweight actuator systems for UAVs and satellites.

Robotics: Agile robotic joint drives, collaborative robot (cobot) wrists, and mobile platform turrets requiring dynamic response.

Medical Technology: Precision positioning arms for surgical robots, MRI components, and radiation therapy equipment.

Optics & Imaging: Smooth pan-tilt for telescope mounts, laser cutters, and high-magnification inspection systems.

Renewable Energy: Lightweight solar tracker drives optimizing panel alignment without excessive structural support.

Defense & Security: Stabilized weapon systems, surveillance sensor turrets, and portable radar arrays.

Understanding SP-I 0741 Price Drivers

Several key factors influence the Lightweight Slewing Ring Gear Drive SP-I 0741 price:

Material Science: Aerospace-grade aluminum alloys (e.g., 7075-T6) and specialized gear steels cost significantly more than standard materials.

Precision Manufacturing: Achieving micron-level tolerances in gear grinding, heat treatment (case hardening), and surface finishing requires advanced CNC equipment and rigorous QC, increasing production costs.

Bearing & Seal Quality: High-performance crossed roller bearings and fluorocarbon seals contribute substantially to unit cost but are essential for durability and low friction.

Customization: Modifications like special input shafts, custom bolt patterns, or unique sealing solutions add cost.

Order Volume: Economies of scale apply; higher-volume purchases typically reduce per-unit costs.

Certification Requirements: Compliance with standards like ISO 9001, AS9100, or specific military specs adds auditing and testing overhead.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0741

When seeking the genuine Lightweight Slewing Ring Gear Drive SP-I 0741 supplier, LYRADRIVE stands as the engineering partner of choice. Beyond mere distribution, LYRADRIVE provides:

Direct Manufacturer Access: Ensuring authentic SP-I 0741 drives with full traceability and warranty support.

Application Engineering: Expert assistance in drive selection, integration support, and custom modification services to tailor the SP-I 0741 to your exact needs.

Global Logistics: Reliable supply chain management for timely delivery worldwide.

Lifecycle Support: Comprehensive maintenance kits, spare parts availability, and technical documentation.

Prototyping Assistance: Support for integrating the SP-I 0741 into new designs, reducing development risks.

The future belongs to lightweight, precise, and powerful motion. The SP-I 0741 Lightweight Slewing Ring Gear Drive isn't just a component; it's an enabler of innovation across industries constrained by weight, space, and the relentless demand for accuracy. By mastering the critical balance between strength, mass, and precision, it unlocks possibilities previously deemed unattainable. Whether soaring in the thin atmosphere aboard a drone, enabling life-saving precision in a surgical suite, or harnessing the sun's energy more efficiently, this drive system proves that sometimes, less weight truly delivers far more capability. Partnering with a technical leader like LYRADRIVE ensures access to this transformative technology and the expertise to deploy it successfully.