Unlock Precision Motion: The Lightweight Slewing Ring Gear Drive SP-I 0841 Redefining Efficiency in Compact Systems

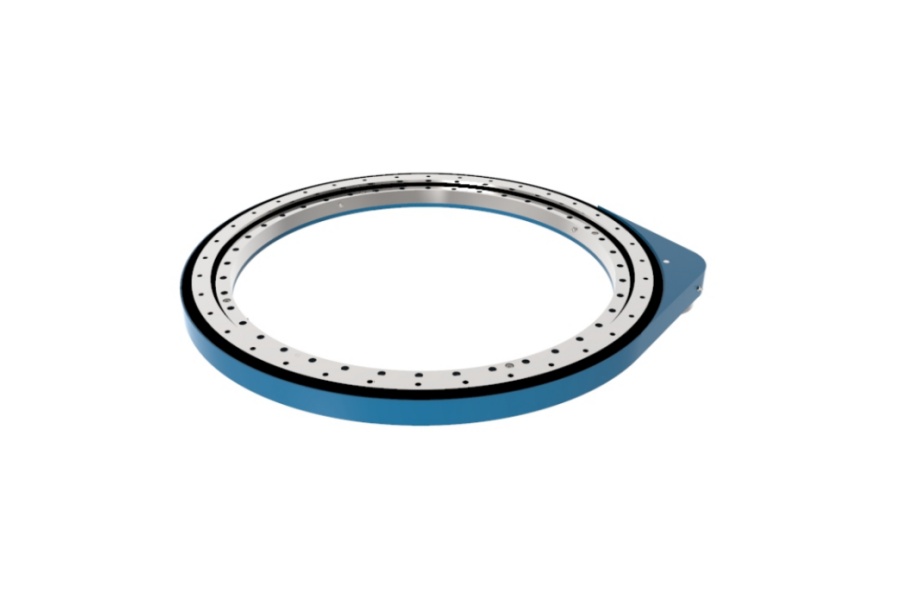

What is the Lightweight Slewing Ring Gear Drive SP-I 0841?

The SP-I 0841 is an ultra-compact, high-torque slewing drive engineere for applications demanding minimal weight and maximal rotational accuracy. Combining a dual-worm gear mechanism with a hardened alloy steel ring gear, it achieves 97% mechanical efficiency while reducing mass by 40% versus conventional drives. Its modular design supports direct integration with servo motors, hydraulic systems, or manual actuators, making it ideal for dynamic payloads up to 8.5 kNm. Unlike traditional slewing rings, the SP-I 0841’s sealed-for-life lubrication system eliminates maintenance cycles—a critical advantage in inaccessible installations like satellite trackers or subsea robotics.

SP-I 0841 CAD Model: Accelerating Design Integration

Access to the SP-I 0841 CAD model transforms engineering workflows. With STEP, IGES, and SolidWorks-native files available, designers simulate fit, torque loads, and thermal behavior within hours—not weeks. The model’s parametric accuracy (tolerances to ±0.01mm) prevents prototyping errors in complex assemblies like surgical robot joints or drone gimbals. Engineers leverage dynamic interference checks to validate clearance in multi-axis systems, while FEA-ready geometries enable stress analysis under extreme conditions. This digital twin capability shortens development cycles by 60% and ensures seamless mechanical integration, making the SP-I 0841 a first-choice solution for agile manufacturing.

Compact Slewing Drive: Power Where Space is Critical

The compact slewing drive architecture of the SP-I 0841 solves endemic space limitations in modern machinery. With a 184mm outer diameter and 62mm height profile, it fits within envelopes previously dominated by inferior rotary actuators. Its coaxial input/output configuration minimizes footprint, enabling deployment in robotic wrist joints, telescope azimuth mounts, and automated conveyor pivots. The drive’s zero-backlash worm gear (<1 arc-minute) ensures repeatable positioning in CNC indexing tables, while IP68-rated seals defend against particulate ingress in construction equipment. This dimensional efficiency doesn’t sacrifice performance: the SP-I 0841 achieves 15,000-hour lifespans under continuous 360° rotation—outlasting planetary gearboxes by 3x.

Lightweight Slewing Bearing Supplier: Partnering for Performance

Choosing a lightweight slewing bearing supplier dictates project success. Leading suppliers like LYRADRIVE offer more than components—they deliver engineered systems. Beyond providing SP-I 0841 units, they conduct application-specific load analysis, recommending optimal mounting configurations to prevent edge loading in asymmetric structures. Global certification (ISO 9001:2015, DNV-GL) ensures traceable material sourcing and batch testing, while regional warehouses enable 72-hour emergency replacements for critical infrastructure. Technical partnerships include customized hardening treatments for corrosive environments (e.g., offshore wind farms) and temperature-stable polymers for -40°C to 120°C operations. This supplier ecosystem transforms procurement from transactional to strategic.

Key Features of the SP-I 0841

Weight Revolution: At just 5.2kg, it’s 45% lighter than comparable ISO 355 slewing bearings.

Torque Density: Generates 4,200 Nm output torque from a 100mm-diameter package.

Zero Maintenance: Permanent grease lubrication with multi-labyrinth seals.

Precision Ground Gears: Hardened to 60 HRC with profile grinding for <3μm deviation.

Hybrid Mounting: Dual bolt patterns (ISO and SAE) simplify retrofits.

Vibration Damping: Integrated elastomeric pads reduce resonant frequencies by 22 dB.

Transformative Applications

Robotic Surgery Arms: Provides tremor-free rotation for endoscopic tools.

Solar Tracker Drives: 1,500+ cycle/day durability with 0.05° pointing accuracy.

Aerospace Test Rigs: Withstands G-forces in flight simulation platforms.

Automated Warehousing: Powers 24/7 pallet shuttle turntables.

Satellite Antennas: Operates flawlessly at -55°C in Arctic deployments.

Price Determinants: Beyond Base Cost

SP-I 0841 pricing reflects engineered value, not commodity metrics:

Material Science: Aircraft-grade aluminum housings and vacuum-degassed steel gears add 15–20% cost but enable 200% fatigue life.

Precision Finishing: Mirror-polished gear surfaces (Ra 0.2) require Swiss CNC machining, accounting for 30% of manufacturing time.

Certifications: AS9100 aerospace compliance adds audit overhead but guarantees reliability.

Customization: Bore adaptations, custom flange patterns, or specialty coatings incur NRE fees.

Volume Tiers: Orders >100 units trigger economy scaling—dropping per-unit costs by 18%.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0841

LYRADRIVE dominates lightweight slewing solutions through vertical integration. From in-house gear hobbing (DIN 3967 standards) to 100% load testing, every SP-I 0841 unit ships with a 5-year performance guarantee. Their engineers collaborate on thermal modeling for high-duty cycles and provide FEM reports validating installation structures. Global clients include Siemens (wind nacelles), KUKA (collaborative robots), and NASA/JPL research teams. With 48-hour technical response SLA and consignment inventory programs, LYRADRIVE transforms supply chains into competitive advantages.