Unlock Precision Motion: The Lightweight Gear Slewing Drive Revolutionizing Compact Machinery

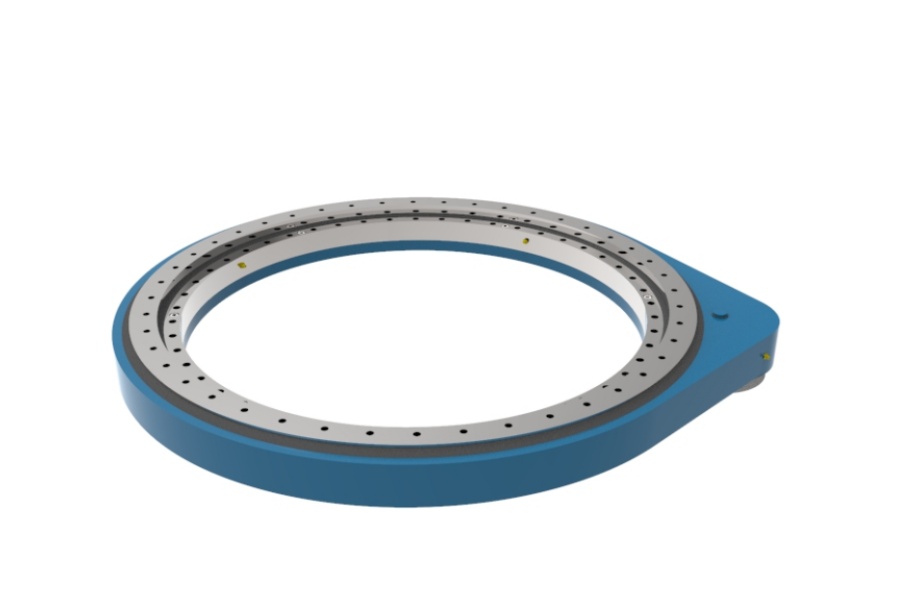

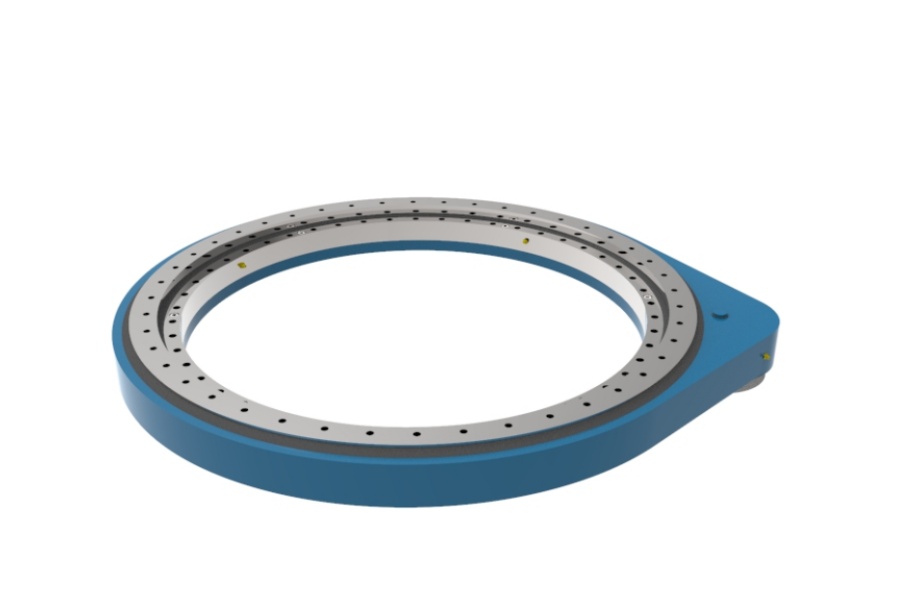

What is the Light Gear Slewing Drive SP-I 0941?

The SP-I 0941 is a highly engineered, compact slewing drive specifically designed for applications prioritizing low weight and minimal space consumption without compromising essential performance. Functioning as an integrated gearbox and bearing system, it facilitates controlled rotation around a single axis under substantial load. Its core components include a robust housing, precision internal gearing (typically a worm gear set for self-locking and high reduction ratios), and a hardened slewing ring bearing that directly handles axial, radial, and moment loads. The "Light" designation signifies its optimized design philosophy, utilizing advanced materials and engineering techniques to achieve significant weight savings compared to standard slewing drives of similar capacity, making it ideal for weight-sensitive and space-constrained designs across diverse industries.

Embracing Compact Design: The SP-I 0941 Advantage

The defining characteristic of the SP-I 0941 is its exceptional compactness. Traditional slewing drives often impose significant dimensional limitations on machinery design. The SP-I 0941 shatters these constraints. Its meticulously engineered housing and internal component arrangement minimize its overall envelope – both in diameter and height. This compactness translates directly into greater design freedom for engineers. It allows for slewing mechanisms to be integrated into tighter spaces, enables the creation of more streamlined equipment profiles, and reduces the overall structural requirements of the supporting framework. This space efficiency is crucial in applications like robotics arms, compact automation cells, portable equipment, and within complex machinery assemblies where every cubic centimeter matters, enabling slewing functionality where it was previously impractical or impossible.

The Heart of Lightness: The Optimized Ring Gear

Central to the SP-I 0941's lightweight performance is its specifically engineered Light Slewing Ring. This critical component undergoes rigorous design optimization. Advanced finite element analysis (FEA) ensures material is strategically placed only where structurally necessary to handle the specified loads – axial, radial, and moment loads – while eliminating non-essential mass. High-strength, lightweight alloy steels are typically employed, often undergoing specialized heat treatment processes like case hardening to achieve an extremely hard, wear-resistant gear tooth surface while maintaining a tough, impact-resistant core. Precision grinding of the gear teeth after heat treatment guarantees optimal meshing with the worm gear, minimizing friction, noise, and backlash. This focus on the ring gear's weight and precision is fundamental to the drive's overall efficiency, low inertia, and smooth, responsive operation, setting it apart from heavier, bulkier alternatives.

Key Characteristics Defining the SP-I 0941

The SP-I 0941 Light Gear Slewing Drive isn't just small and light; it's engineered for performance and reliability:

Exceptional Power Density: Delivers significant torque and load-handling capacity relative to its compact size and weight, maximizing performance in minimal space.

Precision Motion Control: Features low backlash and high positional accuracy, essential for applications requiring repeatable, controlled movements.

Integrated Self-Locking: The inherent design of the worm gear set provides reliable self-locking, holding loads securely in position without needing an external brake (depending on the specific ratio and design).

Smooth & Quiet Operation: Precision manufacturing of gears and bearings ensures low vibration and minimal operational noise, enhancing user comfort and equipment lifespan.

High Efficiency: Optimized gear geometry and quality bearings minimize energy losses during operation.

Robust Sealing: Effective sealing solutions protect internal components from dust, dirt, moisture, and other contaminants, ensuring long service life even in demanding environments.

Simplified Integration: Designed as a pre-assembled, pre-lubricated unit, significantly reducing installation complexity and time.

Corrosion Resistance: Options for surface treatments or specific material grades enhance resistance to corrosion in harsh operating conditions.

Versatile Applications Empowered by Lightweight Rotation

The unique blend of compactness, lightness, and performance makes the SP-I 0941 indispensable across numerous sectors:

Solar Tracking Systems: Ideal for single-axis and smaller dual-axis trackers where minimizing weight on the moving structure is crucial for motor sizing and structural costs.

Robotics & Automation: Enables precise joint rotation in robotic arms, automated guided vehicles (AGVs), welding positioners, and assembly line equipment within tight spaces.

Material Handling: Powers rotation in compact cranes, light-duty hoists, manipulators, and positioning tables used in warehouses and factories.

Medical & Laboratory Equipment: Provides precise, smooth, and quiet rotation for imaging devices, treatment tables, and sensitive lab instrumentation.

Defense & Aerospace: Used in radar platforms, sensor turrets, targeting systems, and ground support equipment where weight and space are at a premium.

Agriculture & Forestry: Powers camera mounts, sprayer arms, and sensor positioning on drones and compact machinery.

Broadcast & Surveillance: Enables smooth panning for CCTV cameras, PTZ cameras, and satellite communication antennas on mobile or lightweight platforms.

Marine & Offshore: Suitable for hatch covers, light-duty crane applications, and equipment positioning on smaller vessels and platforms.

Understanding the Price Factors for SP-I 0941

The investment in an SP-I 0941 Light Gear Slewing Drive is influenced by several key factors:

Precision Engineering & Tolerances: Achieving the required low backlash, high accuracy, and smooth operation demands advanced manufacturing processes and rigorous quality control, impacting cost.

Material Selection & Quality: The use of high-strength, lightweight alloy steels for the ring gear, housing, and worm, along with high-quality bearing components, contributes significantly to the cost but is essential for performance and durability.

Heat Treatment & Finishing: Specialized processes like case hardening, grinding, and superfinishing of gear teeth are critical for wear resistance and longevity but add manufacturing steps and cost.

Sealing & Protection: The complexity and quality of sealing solutions (lip seals, labyrinth seals, specific grease) needed for the application's environmental rating (IP class) affect price.

Customization: While the SP-I 0941 is a specific model, variations in mounting configurations, output flanges, input shaft types, special lubrication, or corrosion protection coatings add cost.

Bearing & Gear Quality: The grade and precision class of the internal slewing ring bearing and the worm gear set are major cost drivers.

Order Volume & Supply Chain: Economies of scale apply; larger orders typically reduce the unit cost. Raw material price fluctuations and logistics also play a role.

Brand Reputation & Support: Manufacturers with proven reliability, extensive testing, and strong technical support often command a premium, reflecting the value of reduced risk and downtime.

Your Trusted Source for Precision Light Slewing Solutions: LYRADRIVE

When seeking a reliable supplier for the high-performance SP-I 0941 Light Gear Slewing Drive, LYRADRIVE stands out as a premier partner. We specialize in the design, engineering, and manufacturing of precision slewing drives, with a deep understanding of the challenges and requirements of compact, lightweight applications. Choosing LYRADRIVE means accessing:

Engineering Expertise: In-house design and application engineering support to ensure the SP-I 0941 is optimally integrated into your system.

Proven Quality & Reliability: Rigorous manufacturing processes, material control, and testing protocols ensure drives meet stringent performance and durability standards.

Technical Support: Dedicated assistance from selection through installation and maintenance.

Customization Capabilities: Ability to tailor standard SP-I 0941 configurations to meet specific application needs (mounting, sealing, input/output options).

Global Supply Chain: Efficient logistics to deliver solutions worldwide.

Commitment to Innovation: Continuous improvement in materials, design, and manufacturing techniques to deliver cutting-edge lightweight slewing technology.

Embrace the Future of Compact Rotation

The Light Gear Slewing Drive SP-I 0941 represents a paradigm shift, demonstrating that power, precision, and reliability need not come at the expense of size and weight. Its innovative design, centered around an optimized light slewing ring and compact housing, unlocks possibilities in robotics, automation, solar energy, medical technology, and countless other fields where spatial efficiency and mass reduction are paramount. Understanding its capabilities, characteristics, and the factors influencing its cost empowers designers and engineers to make informed decisions. Partnering with a specialized supplier like LYRADRIVE ensures access to the engineering support, proven quality, and reliable performance necessary to fully leverage the advantages of this transformative technology. By integrating the SP-I 0941, you invest in enabling lighter, smarter, and more agile machinery for the future.