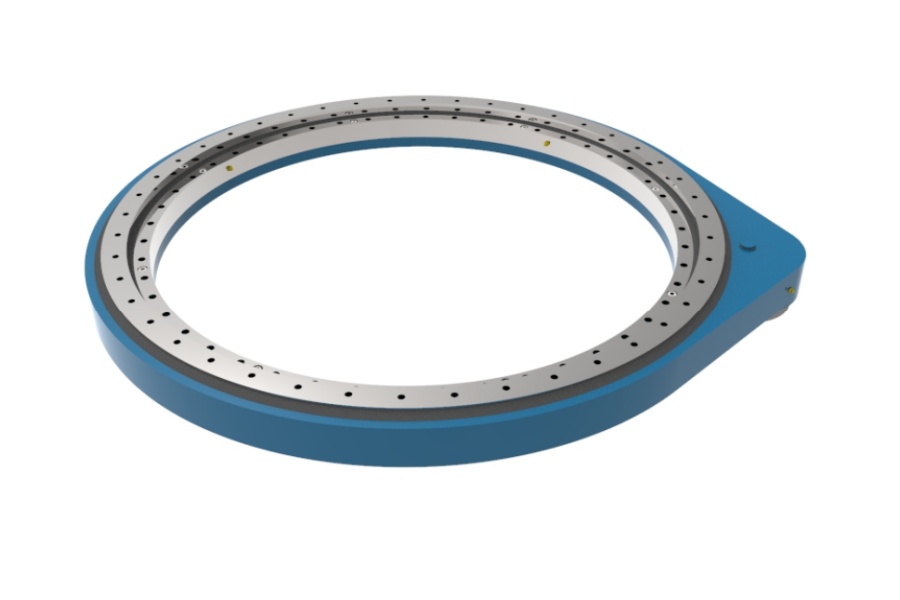

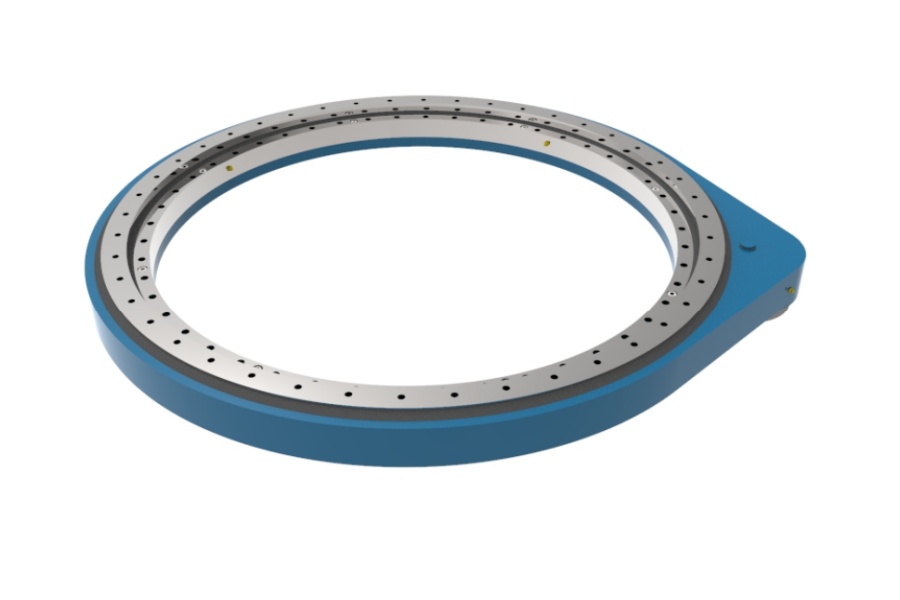

Medium Duty Gear Slewing Drive SP-M 1091 Essential Guide

What is Medium Duty Gear Slewing Drive SP-M 1091

Medium Duty Gear Slewing Drive SP-M 1091 is an advanced mechanical transmission device designed to provide controlled and powerful rotational movement. At its core lies a precision-engineered slewing bearing integrated with a high-quality gear reduction system, typically featuring hardened pinion and ring gears. This unit functions as a complete, self-contained drive system, converting input power from sources like electric motors or hydraulic motors into high-torque, low-speed output rotation. It eliminates the need for complex external gearing arrangements, simplifying machine design, reducing installation complexity, and enhancing overall system reliability. Engineered for medium-load scenarios, it delivers an optimal balance between performance, durability, and cost-effectiveness across diverse sectors.

Selecting Safety Factors for Slewing Drives in Different Working Conditions

Choosing the appropriate safety factor for a slewing drive like the SP-M 1091 is paramount to ensure operational safety, longevity, and reliability. The safety factor represents the ratio between the component's ultimate load capacity and the maximum anticipated operational load. Selection depends critically on the specific application and its operating environment:

Standard Industrial Applications (e.g., Material Handling, Automated Machinery): For predictable loads, stable environments, and controlled operation, a safety factor of 1.5 to 2.0 is often sufficient. This assumes regular maintenance and no significant shock loads.

Applications with Dynamic or Shock Loads (e.g., Construction Equipment, Mobile Cranes): Environments where sudden load changes, impacts, or vibrations are common necessitate significantly higher safety factors, typically ranging from 2.5 to 4.0 or even higher. This buffer protects against unforeseen peak stresses.

Critical Safety Applications (e.g., Personnel Lifting, Medical Equipment, Wind Turbine Yaw/Pitch): Where failure could result in severe injury, loss of life, or catastrophic equipment damage, the highest safety factors are mandatory. Values of 4.0 and above are standard, often dictated by stringent industry regulations and rigorous certification requirements.

Harsh Environmental Conditions (e.g., Offshore, Mining, Extreme Temperatures): Exposure to corrosive elements, abrasive dust, significant temperature fluctuations, or continuous heavy-duty cycles demands increased safety factors, usually between 2.5 and 3.5, to account for accelerated wear and potential material degradation. Fatigue life calculations under variable loads also become crucial.

Always consult the manufacturer's specific recommendations and relevant industry standards (like ISO, FEM, or DIN) for definitive guidance. Underestimating the required safety factor risks premature failure and safety hazards, while overestimating can lead to unnecessary cost and weight penalties.

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 1091

The Medium Duty Gear Slewing Drive SP-M 1091 is engineered with efficiency as a key design principle. Its energy efficiency ratio stems from several integrated features:

Precision Gearing: High-quality manufacturing of the pinion and ring gears ensures minimal friction losses during meshing. Precision grinding and optimized tooth profiles reduce sliding friction and parasitic power consumption.

Optimized Gear Ratio: The inherent design provides a significant mechanical advantage, allowing a smaller, more efficient input motor to generate the high output torque required. This avoids the energy waste associated with oversized prime movers.

Low-Friction Bearings: The integrated slewing bearing utilizes low-friction raceways and optimized sealing systems, minimizing resistance to rotation and reducing the torque needed to overcome internal friction.

Efficient Sealing: Effective sealing (often rated IP65 or higher) prevents lubricant leakage and ingress of contaminants. Clean, adequately lubricated gears and bearings operate with significantly lower friction than contaminated ones, maintaining high efficiency over the long term.

Reduced System Complexity: By integrating the bearing, gearing, and mounting structure, the SP-M 1091 eliminates energy losses that occur in traditional systems using separate components connected by couplings, shafts, and additional bearings.

Compared to less integrated or lower-quality alternatives, the SP-M 1091 requires less input power to achieve the same output torque and speed, translating directly into lower operating costs and a reduced environmental footprint over its lifespan. This high efficiency is particularly valuable in applications running continuously or powered by batteries.

Key Features of Medium Duty Gear Slewing Drive SP-M 1091

The SP-M 1091 distinguishes itself through a combination of robust design and practical features tailored for reliable medium-duty performance:

High Torque Capacity: Engineered to deliver substantial nominal and maximum torque (Md nom and Md max), enabling it to drive significant loads smoothly and reliably under standard and peak conditions. The high maximum holding torque (Mh) ensures stability when stationary.

Exceptional Load Handling: Features high axial (Co ax) and radial (Co rad) static load ratings, along with robust dynamic load capacities (Cax, Crad), allowing it to withstand substantial forces from multiple directions simultaneously, common in complex machinery.

Precision and Rigidity: Manufactured with tight tolerances and high-quality materials, ensuring precise rotational control, minimal backlash, and high system rigidity for accurate positioning and repeatability.

Integrated Design: Combines the slewing bearing, gearing, seals, and often mounting points into a single, compact unit. This simplifies installation, reduces alignment issues, and saves valuable space within machinery.

High Sealing Integrity (IP65): Utilizes advanced sealing technology to achieve IP65 protection, effectively sealing out dust and water jets. This significantly prolongs component life by preventing contamination of the critical gear and bearing interfaces, especially vital in harsh industrial environments.

Versatile Mounting and Drive Options: Designed with flexibility for various mounting configurations. Offers multiple options for input drive connection, accommodating electric motors (with various flanges), hydraulic motors, or manual inputs depending on application needs.

Durability and Long Service Life: Constructed from high-strength materials and subjected to rigorous heat treatment processes. Precision manufacturing and effective sealing contribute to extended maintenance intervals and a long operational lifespan.

Moderate Weight: While robust, the design focuses on achieving necessary strength without excessive weight (W), aiding in overall machine weight optimization.

Diverse Applications of Medium Duty Gear Slewing Drive SP-M 1091

The combination of power, precision, and compact integration makes the SP-M 1091 suitable for a wide array of demanding applications across numerous industries:

Material Handling: Robotic arms, palletizers, depalletizers, conveyor turntables, automated guided vehicle (AGV) rotation modules, and warehouse automated storage/retrieval systems (ASRS).

Construction & Heavy Equipment: Mini excavators, compact cranes, aerial work platforms (boom lifts, scissor lifts - for rotation of the platform or sections of the boom), concrete pump line rotators, and drilling equipment positioning heads.

Industrial Automation: Indexing tables, welding positioners, rotary assembly stations, packaging machinery turntables, and machine tool accessories requiring precise rotary motion.

Transportation & Logistics: Container handling equipment, specialized heavy-duty turntables for vehicle positioning, and lifting deck rotators on transport trailers.

Medical & Specialized Equipment: Advanced imaging equipment (CT/MRI gantry rotation where appropriate), rehabilitation devices, and specialized laboratory automation requiring controlled rotation.

Agriculture: Irrigation system rotators, feed mixing wagon turntables, and specialized harvesting equipment components.

Its ability to handle combined loads, provide precise control, and operate reliably under demanding conditions makes it a versatile cornerstone in modern machinery design.

Factors Influencing Medium Duty Gear Slewing Drive SP-M 1091 Pricing

The cost of an SP-M 1091 slewing drive is determined by several key factors, reflecting the complexity and quality of its construction:

Material Costs: The primary driver. High-grade alloy steels for gears, bearings, and housings, along with specialized seals and high-performance lubricants, constitute a significant portion of the unit cost. Fluctuations in global steel and specialty material prices directly impact the final product cost.

Manufacturing Complexity & Precision: Precision machining of hardened gears and bearing raceways requires advanced CNC machinery and skilled labor. Processes like grinding, heat treatment (carburizing, hardening, tempering), and quality control inspections add substantial cost. Tighter tolerances and lower backlash requirements increase manufacturing time and complexity.

Sealing and Protection Level: Achieving high ingress protection ratings like IP65 necessitates sophisticated multi-lip seal designs and meticulous assembly processes, adding cost compared to basic sealing solutions.

Bearing & Gear Specifications: The size, type (crossed roller, ball), and quality grade of the integrated slewing bearing significantly impact cost. Similarly, gear module, tooth profile (spur vs. helical - helical often costs more due to manufacturing complexity), hardness, and precision grade are major cost factors. Higher load and torque ratings generally require larger or more robust components.

Customization: While the SP-M 1091 is a standard model, modifications like special mounting flanges, unique input shaft configurations, custom gear ratios, or special coatings (e.g., corrosion protection) add engineering and production costs.

Volume and Economies of Scale: Larger purchase volumes typically allow manufacturers to spread fixed costs (tooling, setup) over more units, reducing the per-unit price.

Supply Chain & Logistics: Costs associated with sourcing raw materials, components (like seals or pre-lubrication), and transporting the finished product contribute to the final price. Geopolitical factors and fuel costs can influence this.

Brand Reputation & Quality Assurance: Manufacturers with established reputations for reliability, extensive warranties, and rigorous quality control systems often command premium pricing, reflecting the reduced risk and potential lifetime cost savings for the end user.

Supplier of Medium Duty Gear Slewing Drive SP-M 1091

LYRADRIVE stands as a prominent and trusted supplier of the Medium Duty Gear Slewing Drive SP-M 1091. Renowned for their engineering expertise and commitment to manufacturing excellence, LYRADRIVE focuses on delivering robust, high-performance slewing drives that meet stringent quality and reliability standards. Their solutions, including the SP-M series, are designed to address the demanding requirements of modern industrial automation, construction, renewable energy, and material handling applications, providing customers with efficient and dependable motion control components backed by strong technical support. Choosing LYRADRIVE ensures access to proven technology and reliable product performance.