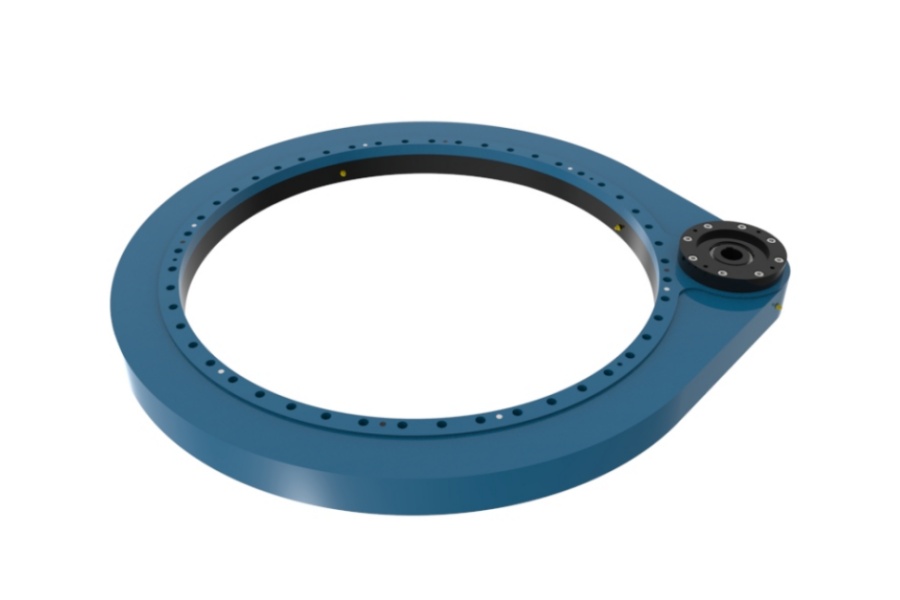

Medium Duty Gear Slewing Drive SP-M 0941 Technical Overview

What is Medium Duty Gear Slewing Drive SP-M 0941?

The Medium Duty Gear Slewing Drive SP-M 0941 is a robust and precise internal gear reduction unit engineered to deliver reliable rotational motion and significant torque capacity within a compact footprint for demanding industrial applications. Medium Duty Gear Slewing Drive SP-M 0941 represents a high-performance internal gear slewing drive solution, specifically designed as an interchangeable equivalent to the IMO Medium Duty Gear Slewing Drive SP-M 0941 model. This crucial component functions as a highly efficient gear reduction mechanism, integral to automating rotational movement in various industrial machinery. At its core, the Medium Duty Gear Slewing Drive SP-M 0941 consists of a large internal gear (the wheel) and a smaller input pinion gear (the worm or spur gear), meticulously manufactured and assembled within a rigid housing structure. This design achieves substantial speed reduction and torque multiplication from a relatively compact input motor. The precision engineering of the gears and the secure mounting provided by the base plate ensure exceptional operational stability and accurate positioning control, making it indispensable for applications demanding high precision and repeatability. By integrating the reduction gear, bearing, and mounting structure into a single, pre-assembled unit, the Medium Duty Gear Slewing Drive SP-M 0941 significantly simplifies mechanical design, reduces installation complexity, and enhances overall system reliability compared to custom-built solutions.

Extreme Temperature Impact on Slewing Drive Performance

The operational environment, particularly extreme temperatures, profoundly influences the performance and longevity of gear slewing drives like the Medium Duty Gear Slewing Drive SP-M 0941. In frigid conditions well below freezing, conventional lubricants experience a significant increase in viscosity, becoming thick and resistant to flow. This thickened grease dramatically increases internal friction within the gear mesh and bearings, leading to a substantial rise in starting torque and running resistance. This translates directly to higher energy consumption and places greater stress on the drive motor. Furthermore, extremely cold temperatures can cause certain metallic components to become more brittle, potentially increasing the risk of fracture under shock loads, although hardened steels used in quality drives like the Medium Duty Gear Slewing Drive SP-M 0941 mitigate this risk significantly. Conversely, exposure to intense heat presents different challenges. Elevated temperatures cause lubricants to thin out, reducing their ability to maintain a protective film between gear teeth and rolling elements. This results in increased metal-to-metal contact, accelerating wear and the risk of scoring or pitting. Prolonged high heat can also lead to lubricant breakdown (oxidation), losing its lubricating properties entirely and forming harmful deposits. Thermal expansion of components is another critical factor; differing expansion rates between the housing, gears, and bearings can alter critical internal clearances. Reduced clearances increase friction and wear, while excessive clearances lead to noise, vibration, reduced positional accuracy, and potential backlash issues. The Medium Duty Gear Slewing Drive SP-M 0941, constructed from high-grade, thermally stable materials and designed with appropriate clearances, inherently offers better resistance to these effects. Its performance envelope can be further extended in harsh environments by specifying specialized high-temperature or low-temperature lubricants during the ordering process and ensuring adequate thermal management (shading, ventilation, or cooling) in the application design.

Medium Duty Gear Slewing Drive SP-M 0941 Energy Efficiency Profile

While specific "energy efficiency ratio" metrics like those for appliances aren't standardly published for individual slewing drive models, the Medium Duty Gear Slewing Drive SP-M 0941 incorporates design features inherently focused on minimizing energy losses, contributing to overall system efficiency. Its core efficiency stems from the precision manufacturing of its hardened and ground gearing. Precise tooth profiles and surface finishes minimize sliding friction and meshing losses during power transmission. The use of high-quality, low-friction bearings further reduces parasitic losses compared to lower-grade alternatives. A well-designed internal sealing system protects against contamination without introducing excessive drag. Crucially, the Medium Duty Gear Slewing Drive SP-M 0941's optimized gear geometry and high-quality materials allow it to transmit its rated nominal torque (16,350 Nm) and handle peak loads up to its maximum torque capacity (21,093 Nm) with minimal internal power dissipation as heat. This means that a greater proportion of the input motor power is effectively converted into useful rotational work at the output, rather than being wasted. When correctly sized for the application and paired with an appropriately efficient motor and drive controller, the Medium Duty Gear Slewing Drive SP-M 0941 contributes significantly to a lower total system energy consumption over its operational lifetime compared to less optimized or poorly maintained drives. Its reliability and durability also mean less frequent replacement and associated manufacturing energy costs.

Key Technical Features of the Medium Duty Gear Slewing Drive SP-M 0941

The Medium Duty Gear Slewing Drive SP-M 0941 distinguishes itself through a combination of robust engineering and precise specifications tailored for reliable medium-duty performance:

High Torque Density: Delivers a substantial nominal torque of 16,350 Nm and a maximum torque capacity of 21,093 Nm within a relatively compact and manageable package weighing 165 kg, offering excellent power-to-weight and power-to-size ratios.

Precision Gearing: Features a module of 6 mm with a wheel boasting 174 teeth (Z2) meshing with a 15-tooth pinion (Z1), achieving a significant reduction ratio of 11.6:1 (i). This ensures smooth motion transmission, accurate positioning, and minimal backlash when properly mounted and preloaded.

Exceptional Load Capacity: Engineered to withstand demanding static and dynamic forces, with rated static radial load capacity (Co rad) of 560 kN, static axial load capacity (Co ax) of 1,320 kN, dynamic radial load capacity (Ca rad) of 210 kN, and dynamic axial load capacity (Ca ax) of 225 kN. This robustness supports significant overturning moments and radial forces.

Rigid Construction & Mounting: The integral housing and precision-machined base provide a stable platform, ensuring optimal gear alignment and minimizing deflection under load, which is critical for maintaining accuracy and longevity.

Integrated Design: Combines the gear reduction, large diameter slewing bearing, and mounting structure into a single, pre-assembled, and sealed unit, drastically simplifying system design, installation, and maintenance.

High Holding Brake Torque: Features a maximum holding (static) torque (MH) of 21,093 Nm, matching its maximum drive torque, ensuring secure positioning even when power is removed, crucial for safety and precision in many applications.

Proven Interchangeability: Designed as a direct replacement for the well-established IMO Medium Duty Gear Slewing Drive SP-M 0941 model, offering flexibility in sourcing and integration into existing platforms.

Diverse Industrial Applications

The balanced combination of torque, precision, load capacity, and compactness makes the Medium Duty Gear Slewing Drive SP-M 0941 highly versatile across numerous sectors requiring controlled rotation:

Material Handling & Cranes: Powers the rotation of crane jibs, knuckle booms, light-duty crane turntables, and rotating platforms on forklifts or automated guided vehicles (AGVs), enabling precise load positioning and maneuverability.

Industrial Automation & Robotics: Provides controlled rotary motion for automated welding positioners, indexing tables, pallet changers, robotic arm bases, and other machinery requiring accurate angular positioning in manufacturing lines.

Construction & Earthmoving Equipment: Used in rotating excavator attachments (e.g., hydraulic hammers, grapples), compact crane attachments, drill rig positioning heads, and light-duty screed finisher adjustments.

Wind Energy: Suitable for smaller wind turbine applications, such as yaw drives for very small turbines or pitch adjustment mechanisms on auxiliary components, where its precision and holding torque are beneficial.

Radar & Antenna Systems: Provides smooth and stable rotation for surveillance radars, satellite communication antennas, and other telecommunication equipment requiring reliable pointing accuracy.

Stage & Entertainment Technology: Powers the rotation of lighting trusses, video screens, and automated stage platforms in theaters and concert venues.

Medical & Simulation Equipment: Used in diagnostic imaging systems (like certain CT scanner components where applicable) and motion platforms for flight or driving simulators requiring controlled rotation.

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0941 Pricing

The price point of a Medium Duty Gear Slewing Drive SP-M 0941 is not fixed and is influenced by several key variables:

Raw Material Costs: Fluctuations in the global prices of high-grade alloy steels used for gears, shafts, and housings, along with specialized bearing steel, directly impact manufacturing costs. The cost of copper alloys for worm gears (if applicable) is also a significant factor.

Manufacturing Precision & Quality: The high level of precision grinding, heat treatment (case hardening), and stringent quality control required for gears and bearings represent a significant portion of the production cost. Tighter tolerances and superior surface finishes command higher prices.

Order Volume & Contract Terms: Significant volume purchases typically benefit from economies of scale, leading to lower per-unit costs compared to single-unit orders. Long-term supply agreements can also influence pricing stability.

Customization & Options: While the Medium Duty Gear Slewing Drive SP-M 0941 is a standard model, options like specific sealing types (e.g., for extreme environments), special corrosion protection coatings (e.g., zinc-nickel, epoxy paint), alternative lubrication (food-grade, high-temp, low-temp), specific shaft configurations (hollow, splined, keyed), integrated brakes, or custom mounting flanges add cost.

Supply Chain & Logistics: Global transportation costs, import/export duties, and local warehousing/distribution overheads contribute to the final landed cost for the customer. Geopolitical factors and fuel prices play a role here.

Market Demand & Competition: Overall industrial demand for slewing drives and the competitive landscape among manufacturers and distributors can influence pricing strategies. Brand reputation for reliability and support also factors into value perception.

Technical Support & Warranty: Suppliers offering comprehensive technical support, application engineering services, and extended warranty periods may reflect these value-added services in their pricing structure.

Supplier of Medium Duty Gear Slewing Drive SP-M 0941

LYRADRIVE is a recognized manufacturer and supplier specializing in high-quality power transmission solutions, including a comprehensive range of slewing drives and gearboxes. The company focuses on engineering robust and reliable products like the Medium Duty Gear Slewing Drive SP-M 0941, designed to meet stringent industry standards for performance and durability. LYRADRIVE emphasizes precision manufacturing processes, rigorous quality control, and responsive customer support to ensure their slewing drives deliver optimal performance in demanding applications worldwide. Their product portfolio caters to diverse sectors such as renewable energy, automation, material handling, and construction, providing engineered solutions for critical rotational motion requirements