Light Load Slewing Bearings: The Rotating Heart of the Precision World, Driving the Core Force of Future Technology

What is a Light Load Slewing Bearing?

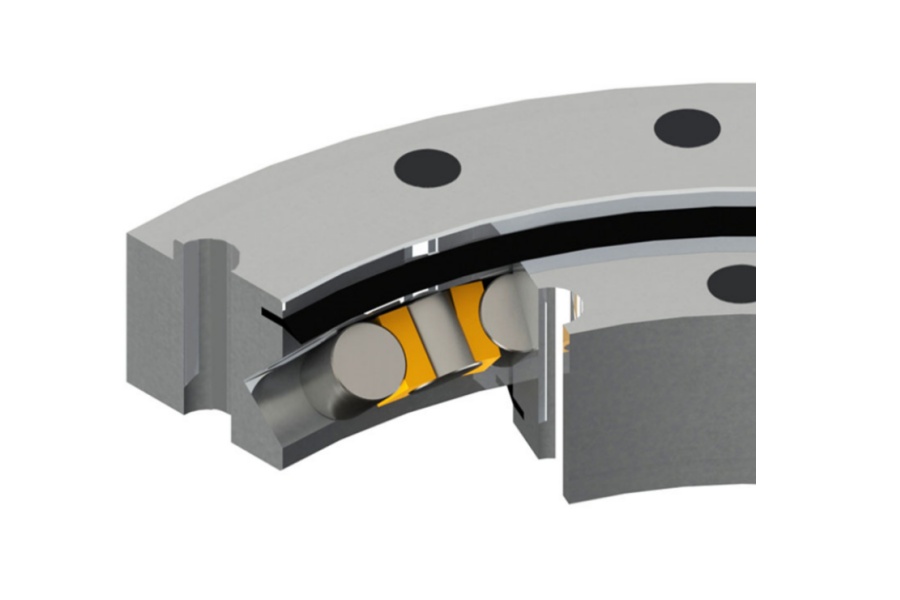

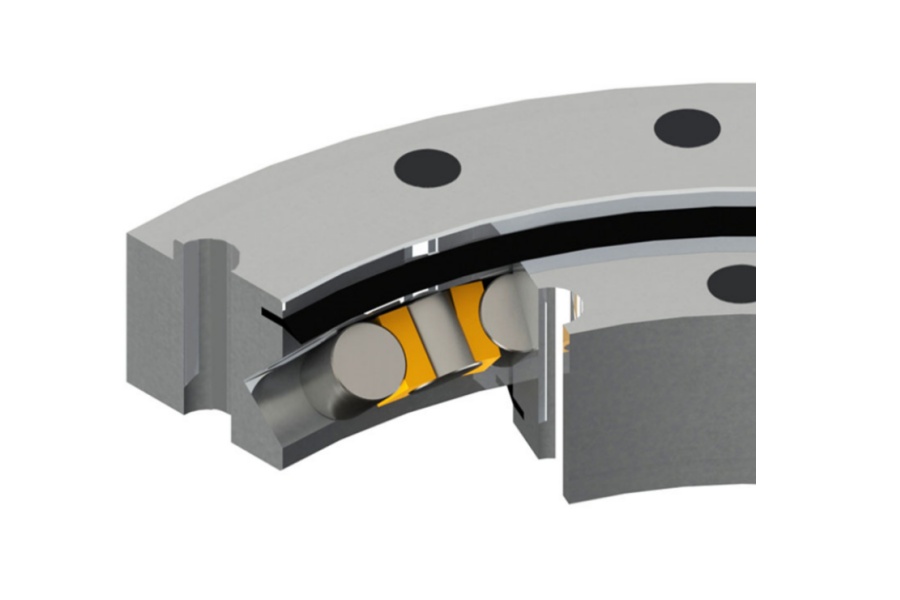

A light load slewing bearing is a revolutionary rotational component designed for confined spaces and precision motion. It delivers near-frictionless smooth rotation while withstanding moderate axial, radial, and overturning forces. Unlike traditional bearings, its core advantages lie in:

Ultra-slim profile: Cross-section height as thin as 15–50 mm

Ultra-low energy consumption: Friction coefficient reduced by over 60%

Absolute silence: Operating noise below 15 dB

Strength-lightness balance: Aluminum alloy construction for optimal rigidity and weight reduction

Featuring single-row ball or crossed-roller structures combined with ceramic hybrid balls and triple-sealing systems, it breathes life into precision equipment on a micron-level battlefield.

Robotic Joint Slewing Bearings: The Invisible Backbone of Flexible Manufacturing

When collaborative robots perform heart surgery with 0.1 mm precision, light load bearings in their joints are making miracles happen:

Zero-backlash transmission: Eliminates motion hysteresis for fluid robotic movements

Integrated smart sensing: Torque sensors detect collision risks in real time

Everlasting lubrication: Self-lubricating polymers achieve 100,000+ hours maintenance-free operation

EMC-compliant design: Shields against signal interference for control system stability

The 7-DOF agility of KUKA’s LBR iiwa robotic arm stems from these bearing arrays thinner than a coin’s diameter.

Medical Equipment Slewing Bearings: Sterile Guardians of Life Sciences

In operating rooms and imaging centers, these bearings must meet stringent medical certifications:

Vacuum-grade sealing: Withstands 135°C high-pressure steam sterilization

Non-magnetic battlefield: Titanium construction ensures zero MRI interference

Particle-free zone: Special polishing technology eliminates tissue contamination risks

Lightning response: Low-inertia design enables CT scanners to rotate at 0.3 seconds per revolution

Within Da Vinci surgical robots’ wristed instruments, miniature bearings achieve ±270° ultra-wide rotation, allowing surgeons to suture blood vessels finer than hair under 10x magnification.

Drone Gimbal Bearing Failure: When Stability Meets Stormy Crisis

During Sahara Desert filming missions, drone bearings face life-threatening challenges:

Salt corrosion killer: Coastal humidity pits raceways with fatal damage

Sand particle assassin: Micro-quartz grains jam precision tracks

EMI interference: Disrupts Hall sensors causing gimbal failure

Lubrication breakdown: Rainwater washes out grease leading to emulsification

DJI’s solution—triple-sealed bearings with graphene-enhanced grease—survives 200+ hours of sandstorms while stabilizing 8K footage in gale-force winds.

Light Load Slewing Bearing Applications

Aerospace: Satellite antenna drive systems withstand 10^-6 Pa vacuum pressure

Semiconductor manufacturing: Wafer-handling robots maintain ISO Class 1 cleanliness

Renewable energy: Small-scale wind turbine pitch systems operate at -40°C

Defense security: Electro-optical reconnaissance turrets achieve >90dB EMI shielding

Consumer electronics: 360° camera rotation modules endure 20,000+ cycles wear-free

Eight Hallmarks of Premium Products

Zero torque fluctuation: Mirror-finished raceways eliminate motion stutter

Corrosion armor: Dacromet coating withstands 1,000+ salt spray hours

Wide-temperature warrior: Specialty grease performs from -73°C to 200°C

Vibration devourer: Nitrile rubber dampers absorb 90% high-frequency oscillations

Smart core: Embedded sensors monitor load and temperature in real time

Lightweight revolution: Aerospace aluminum reduces weight by 60% without sacrificing strength

Custom configurations: Flanged/grooved/thru-bore designs solve spatial constraints

Quietness benchmark: 15 dB operating noise matches human breathing

Decoding Price Variations

Price gaps for identical specs can reach 300%, driven by:

Material upgrades: Medical-grade titanium costs 8x carbon steel

Precision leaps: ABEC-7 tolerance requires 3x machining time

Certification premiums: ISO 13485 compliance adds 40% cost

Sealing revolution: EMI-shielded seals cost 10x standard versions

Volume economics: 10,000-unit orders slash costs by 60% via automation

Extreme protection: Nuclear radiation hardening doubles pricing

The Future: Era of Intelligent Bearings

Sensory bearings: AI chips predict remaining lifespan

Additive manufacturing: 3D-printed topology cuts weight by 30%

Solid lubrication: Molybdenum disulfide coatings eliminate grease

Quantum coatings: Friction coefficients approach theoretical 0.001 limit

The Art of Precision Rotation

From operating tables to Mars rovers, wafer fabs to typhoon eyes, light load slewing bearings are redrawing humanity’s technological frontiers. They shoulder immense responsibilities within square-millimeter spaces, propelling industrial revolutions through silent rotation. As smart manufacturing enters the micron era, these precision components transcend mechanical parts—they are the rotating keys to our future.

Master the core technology of motion to lead industrial transformation.

Supplier of Light Load Slewing Bearing

LYRADRIVE is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.