Light Load Slewing Bearings: Compact Yet Powerful, The Core Hub Driving Precision Worlds

What is a Light Load Slewing Bearing?

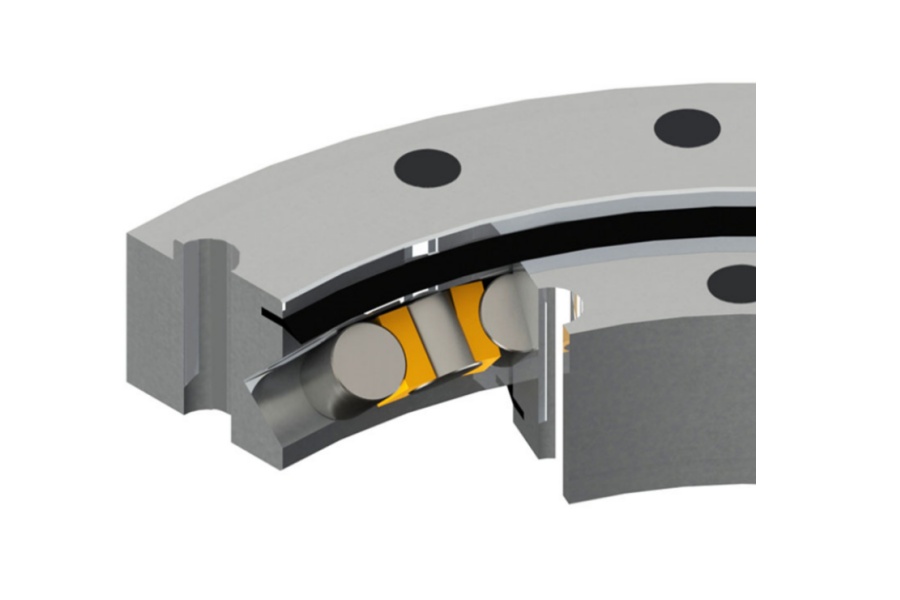

A light load slewing bearing is a fundamental mechanical component specifically engineered to handle relatively small axial forces, radial forces, and overturning moments while facilitating precise, smooth, and continuous rotational movement between two structures. Compared to traditional large slewing bearings, their core characteristics are compact structure, light weight, low friction coefficient, and high rotational accuracy. They typically employ more precise raceway designs and smaller rolling elements (like precision steel balls or short cylindrical rollers), utilizing high-quality seals to minimize friction, prevent contamination, and ensure long service life. This type of bearing is the ideal choice for achieving high-precision rotation within limited space, particularly suited for applications sensitive to weight and demanding low-friction starting torque and quiet operation.

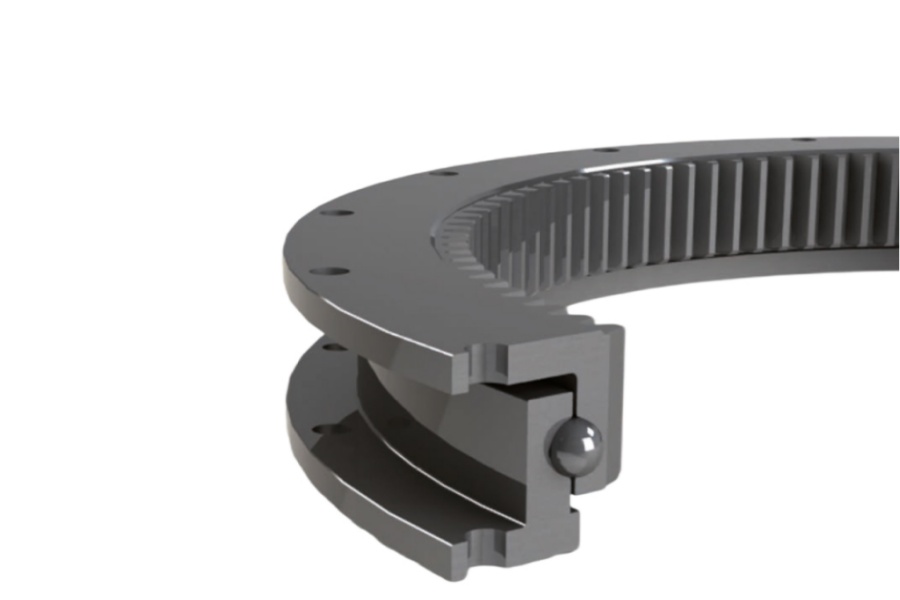

Small Slewing Bearings: The Art of Rotation in the Miniature World

Small slewing bearings are quintessential representatives of the light load family, embodying the "small yet sophisticated" philosophy to the extreme. They usually feature an extremely low cross-section height and compact mounting dimensions, allowing for easy integration into space-constrained designs. Manufacturing these bearings requires exceptionally high process precision and strict quality control to guarantee the geometric accuracy of the raceways, dimensional consistency of the rolling elements, and overall assembly quality. Their low friction characteristics translate not only to lower energy consumption but also smoother starting behavior and quieter running performance. Whether it's a precision optical adjustment platform, a small robotic joint, or a compact radar antenna, small slewing bearings provide the reliable guarantee for micro-scale precision rotation.

Solar Tracker Slewing Bearing Small: Sun-Tracking Precision, The Secret Weapon for Energy Multiplication

In the rapidly growing solar energy sector, small light load slewing bearings are the core dynamic joints of single-axis and some dual-axis solar tracking systems. Driving the precise alignment of photovoltaic panels mounted on support structures with the sun's trajectory is key to maximizing power generation efficiency. These applications impose unique demands on the bearings: Firstly, they require extremely low rotational friction torque, ensuring even small motors can effortlessly drive the entire array, minimizing system energy consumption. Secondly, they must possess outstanding weather resistance and corrosion resistance to withstand long-term outdoor exposure to sun, rain, wind, sand, and temperature/humidity fluctuations. Simultaneously, the characteristic of being maintenance-free for extended periods is crucial, significantly reducing the operational costs of solar power plants. Small slewing bearings specifically optimized for solar trackers, featuring special seals, surface treatments, and lubrication solutions, perfectly meet these challenges, becoming the unsung heroes enhancing the power generation efficiency of photovoltaic installations.

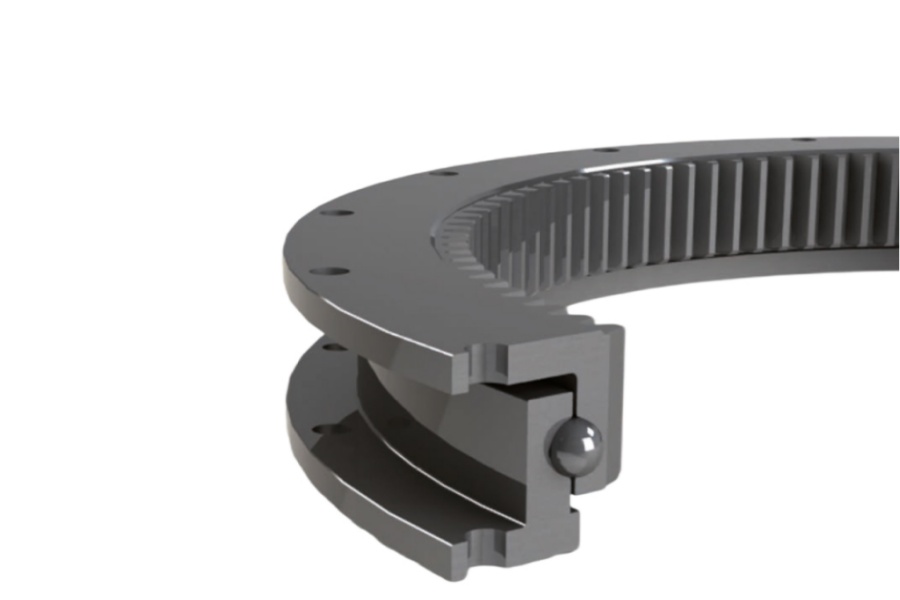

Flanged Slewing Bearing Design: Flanged for Stability, Designed for Convenience

The flanged design is a common and highly practical structural form within light load slewing bearings. This design incorporates a radially extending flange on one or both rings (usually the outer ring), featuring evenly distributed mounting holes. The advantages offered by the flange are clear:

Effortless Installation: The bolt holes on the flange allow the bearing to be directly, quickly, and accurately bolted to adjacent structural components, greatly simplifying the assembly process.

Robust Support: The flange structure effectively increases the mounting contact area, significantly enhancing connection rigidity and stability, particularly beneficial for resisting overturning moments.

Simplified Structure: In many cases, the flange design can eliminate the need for additional, complex mounting flanges or support housings, simplifying the host machine's structural design and reducing overall weight and manufacturing costs.

Reliable Sealing Foundation: The flange edge provides a more stable mounting base for high-quality radial seals, enhancing the bearing's dust and water protection capabilities.

This design makes them the preferred choice for applications like light robotic arms, small turntables, and medical device rotation modules that demand easy installation and solid support.

Applications of Light Load Slewing Bearings: Precision Rotation Everywhere

The application areas for light load slewing bearings are incredibly vast. Their core value lies in providing efficient, reliable, and low-maintenance rotational solutions for a wide array of equipment:

Solar Energy: As mentioned, they are core components for rotation drives in single/dual-axis solar trackers.

Automation & Robotics: Joints in light industrial robots, wrists in collaborative robots, rotation mechanisms for Automated Guided Vehicle (AGV) lifting tops, precision assembly turntables, small indexing tables.

Medical & Laboratory Equipment: Rotating gantry components in CT/MRI imaging systems, surgical robot joints, centrifuges, rotating stages for precision microscopes, laboratory automation instruments.

Security & Surveillance: Rotation mechanisms for speed dome cameras, PTZ cameras, azimuth/elevation drives for small radar/communication antennas.

Packaging & Food Machinery: Rotating stations in small filling machines, labeling machines, sorting equipment.

Precision Instruments & Optical Devices: Equatorial mounts for telescopes, theodolites, rotating mirror platforms in laser equipment, rotating stages for optical inspection devices.

Auxiliary Construction Equipment: Rotation mechanisms for small aerial work platforms, slewing supports for light truck-mounted cranes.

Testing Equipment: Material fatigue testers, small environmental simulation turntables.

Characteristics of Light Load Slewing Bearings: Lightweight Build, Exceptional Performance

Light load slewing bearings excel in diverse fields thanks to their distinct performance characteristics:

Compact Structure, Lightweight: Optimized design delivers functionality within minimal space, ideal for space and weight-sensitive applications.

Low Friction, High Sensitivity: Precision raceways, high-quality rolling elements, and optimized seal designs ensure minimal starting and running friction torque, enabling sensitive, smooth rotation.

High Rotational Accuracy: Stringent manufacturing tolerances guarantee precise rotational positioning and smooth running, meeting the demands of high-precision equipment.

Quiet Operation: Low friction and precision fit result in quiet running characteristics, suitable for medical, laboratory, or office environments requiring low noise.

Easy Maintenance, Long Life: Typically feature long-life grease and high-quality seals, designed for maintenance-free operation or long maintenance intervals, significantly reducing ownership costs.

Good Rigidity: Provide sufficient rigidity even under light loads to maintain rotational accuracy and stability.

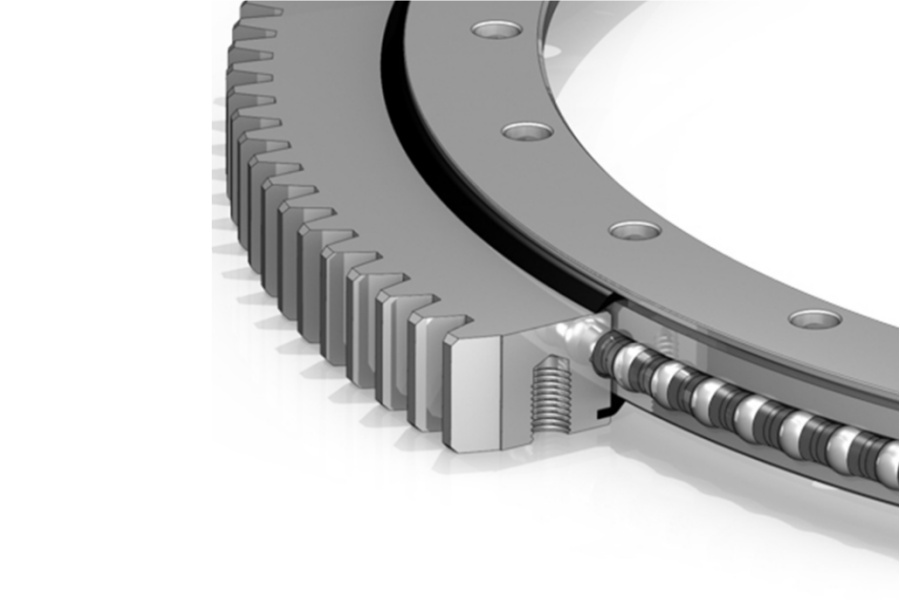

Diverse Mounting Options: Available with gear rings (internal or external) or without, with flanges or flat mounting faces, various seal types (rubber seals, labyrinth seals), adapting to different drive methods and installation needs.

Excellent Corrosion Resistance: Can be supplied with different surface treatments (e.g., zinc plating, Dacromet, stainless steel material) based on the application environment to enhance rust protection.

What Influences the Price of Light Load Slewing Bearings?

The price of a light load slewing bearing is not fixed; it is influenced by several key factors:

Size & Specification: The bearing's diameter, height (cross-section), and structural type (single-row/double-row ball, crossed roller, flanged/non-flanged) are the most basic pricing factors. Larger sizes and more complex structures generally mean higher costs.

Load Capacity & Accuracy Grade: Higher design load capacity (axial force, radial force, overturning moment) demands better materials, heat treatment, and manufacturing precision, increasing the price. Similarly, higher requirements for rotational accuracy (runout tolerance) and running smoothness (e.g., ABEC grade) increase manufacturing costs.

Material & Manufacturing Process: The grade and quality of steel used for the rings (e.g., purity, hardenability), precision grade of rolling elements (balls or rollers), heat treatment process (e.g., carburizing depth, hardness control), precision level of grinding and superfinishing all directly impact performance and cost. Special materials (e.g., stainless steel) cost significantly more than standard bearing steel.

Gear Ring Configuration: Whether a gear ring (internal or external) is required and its precision grade (e.g., ground teeth) substantially increases machining difficulty and cost.

Sealing System: The type of seal (single-lip/double-lip rubber seal, contact/non-contact labyrinth seal), material (e.g., high-temp resistant, oil-resistant rubber), and complexity (e.g., multi-lip seals) affect dust/water protection performance and price.

Surface Treatment & Corrosion Resistance Requirements: The choice between standard zinc plating, eco-friendly Dacromet, special coatings, or stainless steel material involves significant cost differences. High-grade protection needed for harsh environments (high salt spray, humidity) drives prices up.

Lubricating Grease: The type of pre-filled grease (general-purpose, wide-temperature, long-life, food-grade), brand, and fill quantity also influence the initial cost.

Brand & Origin: Well-known international brands often command higher prices due to technology, quality assurance, and brand premium. Manufacturing costs (e.g., labor, energy, logistics) and supply chain efficiency in different origins also affect the final price.

Order Quantity & Customization Level: Bulk purchases usually secure better unit prices. Highly customized bearings (non-standard sizes, special materials, special tolerances, special interfaces) incur much higher costs due to dedicated design, process setup, and production.

Market Supply/Demand & Raw Material Costs: Fluctuations in the prices of raw materials like steel and alloys, as well as market supply/demand conditions at specific times (e.g., capacity tightness or surplus), can have an immediate impact on bearing prices. Global supply chain conditions are equally important.

Lightweight Rotation, Driving Infinite Possibilities

Light load slewing bearings, with their precise construction, lightweight form, and exceptional performance, have quietly become the indispensable "rotating heart" within modern precision machinery and efficient equipment. From solar panels capturing every ray of sunlight to medical imaging devices exploring the mysteries of life; from the agile movements of industrial robot arms to the vigilant scanning of intelligent surveillance PTZ cameras, they are everywhere, silently driving innovation and efficiency. Understanding their definition, types, design features, application scenarios, core advantages, and price determinants is crucial for engineers making optimal selection choices during product design and for procurement personnel balancing cost and value. In the future industrial landscape pursuing miniaturization, intelligence, and sustainability, light load slewing bearings will continue to leverage their "compact yet powerful" nature to showcase the infinite allure of precision rotation on an ever-broader stage.

Supplier of Slew drive

LYRADRIVE is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.