Light Load Slewing Bearings: The Precision Core of a Silent Revolution

What is a Light Load Slewing Bearing

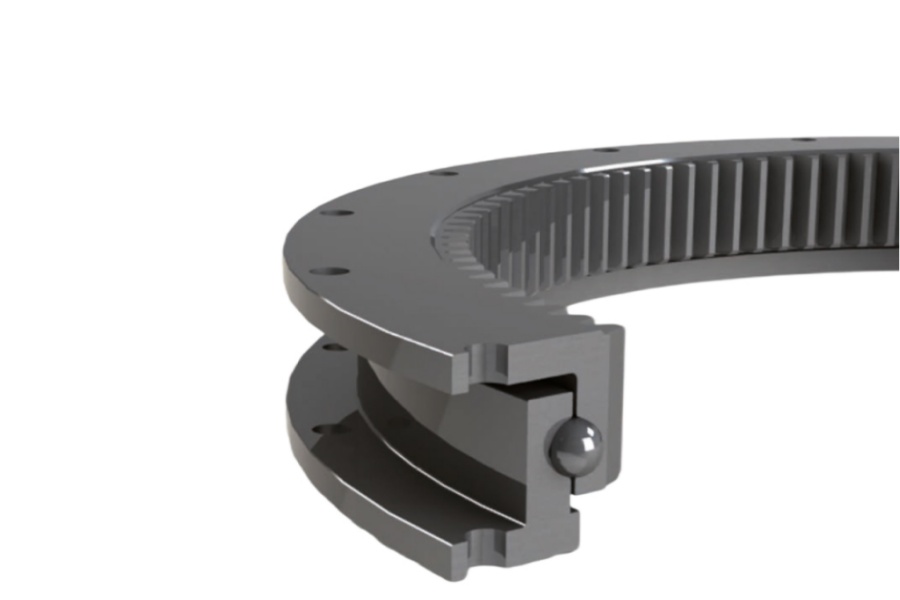

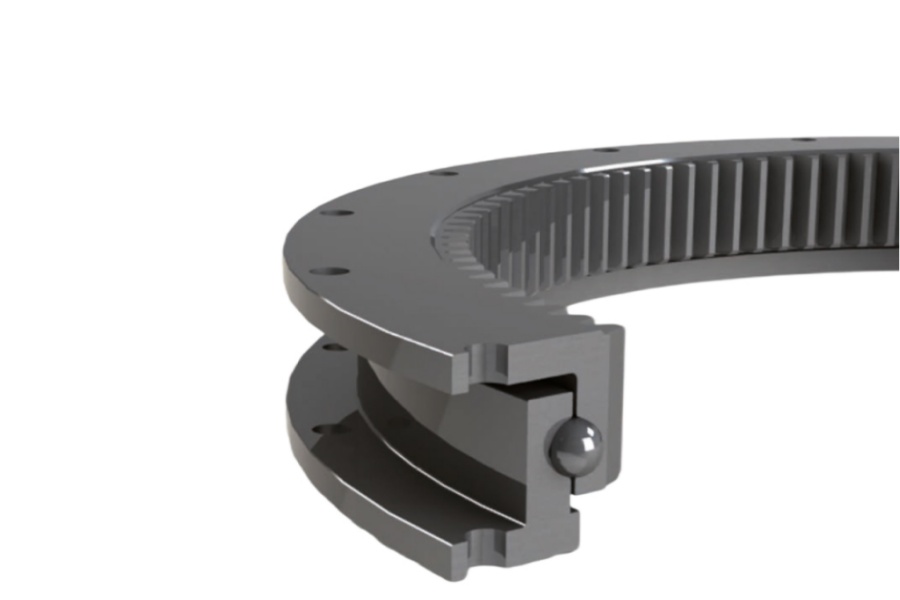

A light load slewing bearing is a revolutionary rotational component engineered for confined spaces and precision transmission. While withstanding moderate axial forces (typically <5kN) and radial loads (<3kN), it achieves ultra-smooth motion with friction coefficients below 0.002. Its fundamental distinctions from traditional bearings include:

Extreme Slimness: 8-35mm cross-section height

Energy Efficiency Revolution: 70% reduction in starting torque

Absolute Silence: Operational noise <20dB(A)

Rigidity-Weight Balance: Aerospace aluminum alloys achieve breakthrough strength-to-weight ratios

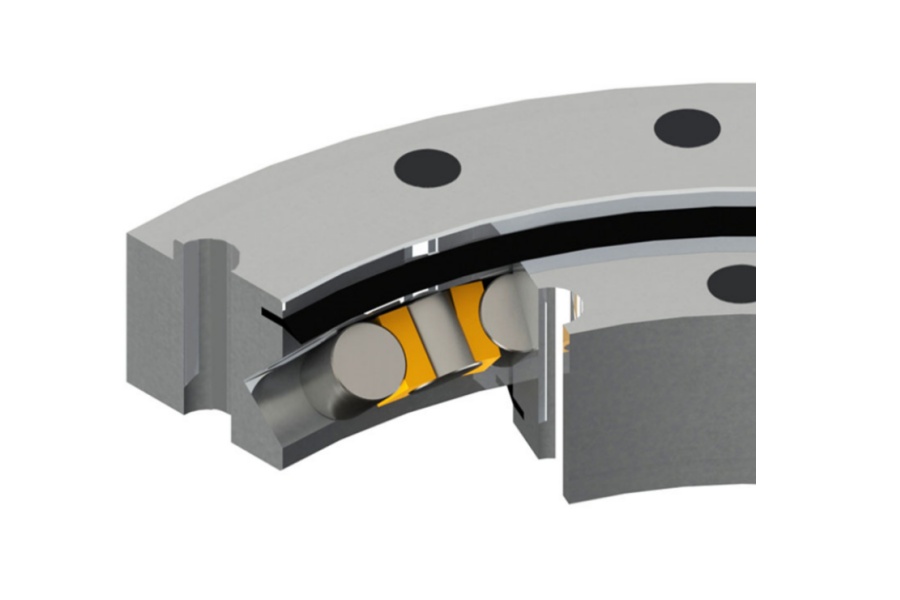

Featuring single-row four-point contact balls or crossed roller structures combined with ceramic-coated raceways and double-lip labyrinth seals, it breathes life into precision equipment on a micron-scale battlefield.

Camera Pan-Tilt Slewing Bearings: The Stabilizing Soul of Visual Capturers

When cinematic cameras achieve 0.01° precision focus tracking, pan-tilt bearings create optical miracles:

Zero Inertial Lag: 180°/s² angular acceleration without jitter

Thermal Drift Compensation: Self-correcting deformation from -30°C to 60°C

EMI-Stealth Design: Eliminates interference with microphone signals

Permanent Lubrication: Vacuum-sealed PFPE grease enables 10-year maintenance-free operation

At the core of ARRI Trinity stabilizers lies a 12mm-thick crossed roller bearing, enabling 4K recording without jelly effect during 200 micro-adjustments per second.

Packaging Machine Turntable Bearings: High-Speed Rotation’s Precision Magician

Facing harsh conditions of 120 start-stop cycles per minute, packaging line turntable bearings demonstrate astonishing performance:

Start-Stop Endurance King: <3μm wear after 10 million cycles

Dynamic Balancing Art: Compensates ±0.2g imbalance automatically

Sterile Protection Shield: FDA-certified seals block microbial invasion

Energy Recycler: Magnetorheological damping converts braking energy into power

In Tetra Pak filling lines, 25mm-thin bearings achieve 0.03s positioning accuracy, enabling 30,000 aseptic packages per hour.

Post-Installation Bearing Noise: The Silent Dream’s Destroyer

When a new medical CT unit emits a "humming" noise upon startup, critical risks may lurk:

Preload Failure: Over-tightening causes 60% extra friction heat

Mounting Surface Warpage: 0.05mm/m flatness deviation triggers stress concentration

Resonance Trap: Natural frequency clashes with bearing’s critical speed

Seal Avenger: Overloaded sealing lips generate squeal

Siemens’ solution—laser interferometer calibration and acoustic camera diagnostics—reduces 3T MRI noise to 32dB.

Global Applications of Light Load Slewing Bearings

Film Industry: Motorized dolly heads with 0.001° repeatability

Medical Imaging: PET-CT gantry rotation under 0.5g centrifugal force

Food Packaging: Chocolate coating turntables resisting food-grade chemicals

Lab Equipment: Centrifuge rotors with <2μm vibration at 2000rpm

Security Systems: Smart PTZ cameras locking faces at 40m distance

Semiconductor: Wafer inspection tables operating stably at 10⁻⁶Pa vacuum

Seven Genetic Codes of Elite Products

Ultra-Smooth Texture: Nano-polished raceways (Ra0.05 roughness)

Corrosion Terminator: Plasma nitrided layer (HV1100 hardness, >2000h salt spray resistance)

Extreme-Temperature Warrior: Synthetic perfluoropolyether grease (-80°C~250°C)

Vibration Devourer: Silicone damping rings absorbing 92% high-frequency harmonics

Lightweight Revolution: Carbon-fiber-reinforced PEEK cages reducing weight by 70%

Smart Sentinel: Embedded piezoelectric sensors detecting micro-cracks

Silence Tech: Acoustically optimized channels eliminating air-turbulence noise

Decoding the Price Maze

Price variations up to 400% hinge on critical factors:

Material Alchemy: Silicon nitride balls cost 15x more than steel

Precision Pyramid: ISO P2 tolerance requires 5x more machining time than P5

Certification Cost: FDA+ISO13485 compliance adds 55% overhead

Sealing Innovation: Magnetic fluid seals priced 20x higher than rubber

Extreme Environment Tax: Gamma-ray resistance doubles pricing

Volume Economics: 100k-unit orders reduce costs 45% via continuous quenching

Logistics Premium: Air freight for precision bearings adds 30% expense

The Future: Dawn of Silent Rotation

Self-Sensing Bearings: AI chips diagnosing remaining lifespan

Micro-Deformation Structures: Shape-memory alloys compensating thermal displacement

Molecular Lubrication: Diamond-like carbon coatings enabling zero wear

Quantum Silence: Phononic crystal structures blocking vibration transmission

Silence isn’t luxury—it’s the dignity of precision motion

From cameras capturing starlight to CT scanners mapping life, from perfect chocolate coating to nanometer wafer inspection, light load slewing bearings propel industrial revolutions through silent rotation. As the world pursues lighter, quieter, and more precise solutions, these engineering marvels prove: True core technology often resides in the quietest spin.

Master the art of silent rotation to lead the precision manufacturing era.

Supplier of Light Load Slewing Bearing

LYRADRIVE is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.