Light Load Slewing Bearing Manufacturing Relies Not Just on Equipment But on Critical Soft Skills

What is Light Load Slewing Bearing

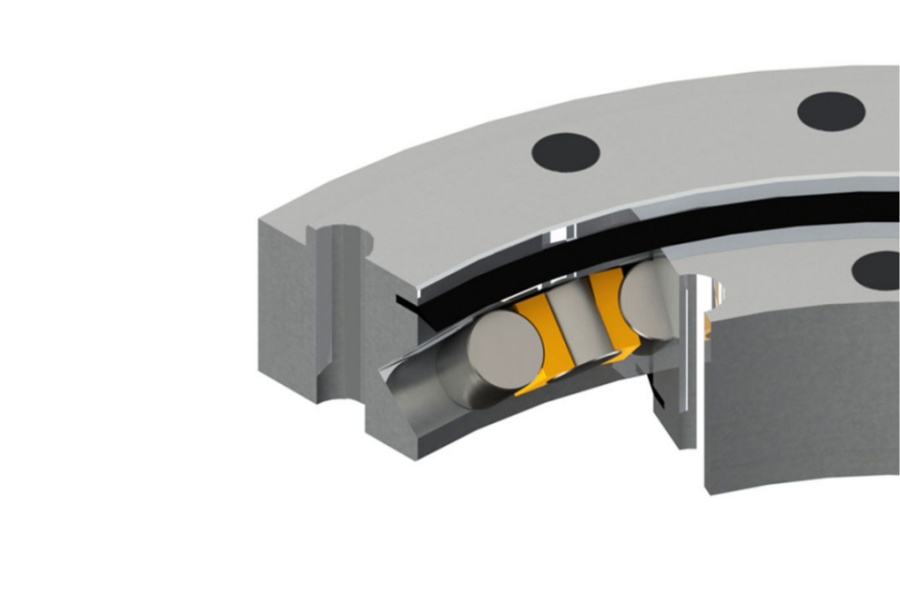

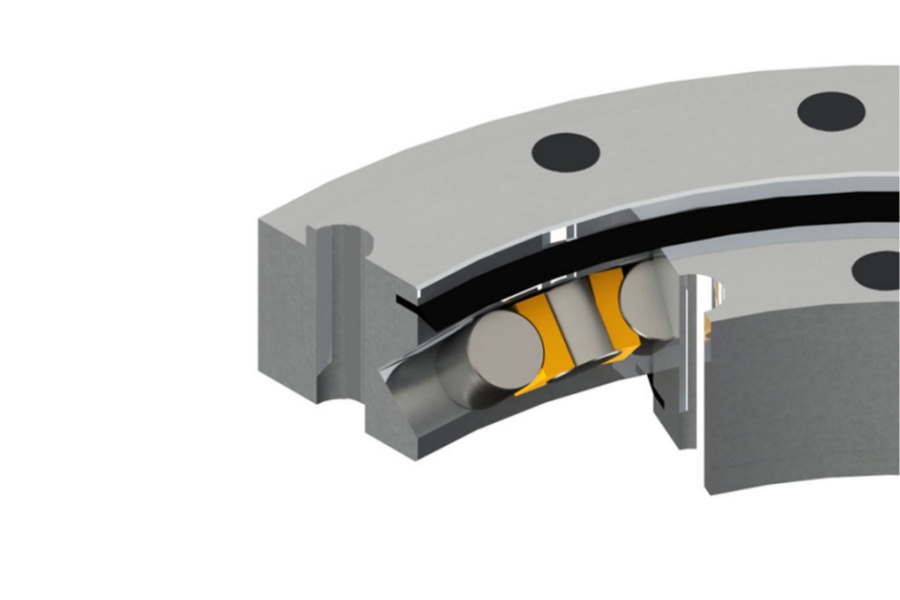

Light Load Slewing Bearing represents a specific category of rotary rolling-element bearing engineered to accommodate combined loads—axial, radial, and moment loads—while facilitating smooth rotational movement between two mechanical assemblies, all while being designed for applications where the imposed forces are relatively modest. Unlike their heavy-duty counterparts found in massive cranes or excavators, these bearings are optimized for scenarios where weight, compactness, and precision often take precedence over sheer load-bearing capacity. The fundamental design typically involves a single row of ball bearings, either four-point contact balls or crossed rollers, seated within integral raceways machined into two bearing rings. This configuration provides a highly efficient and compact solution for 360-degree rotation. The term "light load" is relative and context-dependent, generally referring to applications where the bearing is not subjected to the extreme forces seen in heavy industrial machinery but still requires exceptional reliability and performance within its designated operational envelope. Their construction often utilizes high-quality steel but may also incorporate advanced materials or coatings to enhance corrosion resistance, reduce weight, or minimize friction, making them indispensable in modern, precision-driven industries.

Production of Slewing Bearings Relies Not Just on Equipment But on Soft Power

While state-of-the-art CNC lathes, grinding machines, and heat treatment facilities are visibly crucial in the production of slewing rings, their presence alone is insufficient to guarantee a superior product. The manufacturing of a reliable light load slewing bearing is a complex symphony conducted not by machines, but by human expertise, meticulous processes, and a deeply ingrained culture of quality—collectively known as soft power. This intangible asset is what truly separates exceptional manufacturers from mediocre ones. The first critical element of soft power is metallurgical knowledge and engineering design expertise. Engineers must possess a profound understanding of material science to select the appropriate grade of steel and determine the optimal heat treatment process, such as case hardening or through hardening, to achieve the perfect balance between a tough, wear-resistant surface and a ductile, shock-absorbing core. This knowledge directly impacts the bearing's fatigue life, resistance to brinelling, and overall durability under operational stresses.

Beyond material science, sophisticated design and simulation capabilities form another pillar of soft power. Before any metal is cut, engineers use advanced software for Finite Element Analysis (FEA) to simulate how the bearing will perform under various load conditions. They can identify potential stress concentrations, optimize the geometry of the raceways and gear teeth (if integrated), and virtually validate the design's integrity. This digital prototyping prevents costly mistakes and ensures the final product is engineered for maximum performance and longevity. Furthermore, the integration of precision gearing onto the bearing rings demands exceptional skill in design and manufacturing to ensure perfect meshing and smooth power transmission, a task that goes far beyond simple machining.

Perhaps the most significant manifestation of soft power is an uncompromising quality control (QC) regime. This is a cultural mindset that permeates every step of the production process, from raw material inspection to final packaging. It involves statistical process control (SPC) to monitor machining tolerances, coordinate measuring machines (CMMs) for verifying geometric accuracy, and advanced equipment for testing surface hardness and microstructure. Skilled technicians must meticulously inspect every raceway for surface finish and any microscopic imperfections that could initiate a crack. A robust quality system like ISO 9001 provides a framework, but its effective implementation relies on a dedicated and vigilant workforce that takes personal pride in producing flawless components. This human element of diligence and critical scrutiny cannot be automated away.

Finally, soft power is evident in a company's ability to provide comprehensive technical support and customized solutions. Clients often require bearings with specific mounting holes, seals, lubrication fittings, or performance characteristics. The engineering team's ability to collaborate with the customer, understand their unique application challenges, and tailor a product accordingly is a immense value-add that pure manufacturing equipment cannot provide. It is this combination of deep technical knowledge, rigorous process discipline, a quality-centric culture, and customer-focused innovation that transforms raw materials and sophisticated machines into a high-performance, reliable light load slewing bearing. The machine provides the means, but the soft power provides the excellence.

Characteristics of Light Load Slewing Bearing

Light Load Slewing Bearings possess a distinct set of characteristics that make them ideally suited for their designated applications, differentiating them from heavier-duty versions. Understanding these traits is essential for proper selection and application. The most prominent feature is their compact and lightweight design. Engineers achieve this by utilizing smaller cross-sections and optimized material profiles without compromising structural integrity for the intended loads. This reduction in weight and size is a critical advantage in applications where minimizing overall system weight is paramount, such as in robotic arms or satellite antennas, contributing to improved energy efficiency and faster movement.

Another defining characteristic is their high precision and smooth operation. Light load applications often involve precise positional control or continuous, low-friction rotation. Consequently, these bearings are manufactured with exceptionally tight tolerances on raceway geometry, ball size, and sphericity. The raceways are often ground to a super-finished surface to minimize rolling friction and ensure consistent, smooth, and quiet operation without stick-slip phenomenon. This precision is crucial for applications like optical scanners or medical imaging equipment where vibration or erratic movement would be detrimental.

Integrated functionality is a common and highly valuable trait. To save space and simplify assembly for OEM designers, light load slewing rings frequently come with built-in features. The most common integration is a precision-machined gear on the inner or outer ring, creating a ready-to-drive rotational module. Others may include custom-drilled mounting bolt patterns, various sealing solutions to protect against dust and moisture, and pre-drilled holes for lubrication fittings. This level of integration reduces the number of parts a manufacturer must source and assemble, streamlining production and enhancing overall system reliability.

Despite being designed for lighter duties, these bearings exhibit excellent rigidity and moment load capacity relative to their size. The fundamental four-point contact or crossed roller design inherently provides robust support against tilting moments, ensuring stability and accuracy in the supported platform. Furthermore, they are often engineered for low maintenance requirements. With effective seals retaining high-quality grease, many light load slewing bearings are lubricated for life, requiring no end-user maintenance throughout their long service life, which is a significant benefit in hard-to-reach or maintenance-averse applications. Finally, material versatility is a key characteristic. While high-carbon chromium steel is standard, many are available in stainless steel or with special coatings like zinc-nickel or chromium plating for exceptional corrosion resistance in harsh environments, such as those found in food processing, marine, or medical applications.

Applications of Light Load Slewing Bearing

The unique combination of compact size, precision rotation, and load-handling capability makes the Light Load Slewing Bearing a fundamental component across a vast and diverse range of modern industries. Their application is wherever controlled, reliable rotation is needed under modest to moderate loads. In the realm of robotics and automation, they are ubiquitous. They form the core rotational joints in robotic arms used for assembly, welding, painting, and packaging, providing the precise and rigid movement essential for repeatable accuracy. They are also found at the base of automated guided vehicles (AGVs) and in rotary tables for CNC machining centers and coordinate measuring machines (CMMs), where they enable precise part positioning.

The renewable energy sector is a major consumer of these components. Light load slewing bearings are integral to solar tracking systems, both in large-scale solar farms and smaller residential installations. They enable photovoltaic panels to smoothly rotate and tilt throughout the day, precisely following the sun's path to maximize energy capture. Similarly, they are used in the yaw and pitch control mechanisms of small-scale wind turbines, adjusting the blades to optimally catch the wind. The medical industry relies heavily on their precision and reliability. They are found in the movable arms of surgical lights and microscopes, allowing medical staff to position them effortlessly and without drift. They are also critical components in advanced imaging equipment like CT scanners and X-ray machines, facilitating the precise movement of heavy imaging modules around the patient.

In defense and aerospace, their applications are critical. They are used in radar and satellite communication antennas for both ground stations and on naval vessels, ensuring stable and accurate pointing and tracking. Periscopes in submarines and optical sighting systems in various platforms also utilize these bearings for smooth and precise manual or powered rotation. The industrial and construction sector uses them in a lighter capacity than giant excavators, finding homes in manlifts, aerial work platforms, and light-duty material handling equipment for rotational movement. The entertainment industry employs them in the pan-and-tilt mechanisms of professional film and broadcast camera heads, allowing cinematographers to achieve smooth, fluid movements. Even everyday consumer products like rotating platforms for televisions, smart displays, and certain types of furniture utilize miniature versions of light load slewing bearings. This incredible diversity underscores their role as a key enabling technology in countless devices that define modern life.

Factors Influencing the Price of Light Load Slewing Bearing

The cost of a Light Load Slewing Bearing is not a fixed value but is determined by a complex interplay of several factors, reflecting the materials, labor, and technology invested in its production. Understanding these factors helps in making informed purchasing decisions and appreciating the value proposition of different suppliers. The most significant cost driver is often the raw material. The grade, quality, and quantity of steel required have a direct impact. Bearings made from standard chrome steel (e.g., 42CrMo4 or 50Mn) are common, but those requiring corrosion-resistant stainless steel (e.g., 440C or 316) command a higher price due to the more expensive base material and the increased difficulty in machining and heat treating it. The overall dimensions—diameter, width, and height—also directly influence material cost.

The complexity of the manufacturing process is another major factor. A standard, off-the-shelf bearing will be less expensive than a fully customized one. Customizations such as integrated precision gearing (including the gear type, module, and accuracy class), special drilling patterns for mounting, specific types of seals (e.g., rubber, labyrinth, or felt), and special surface treatments (e.g., zinc plating, black oxide, or Teflon coating) all add significant steps to the machining and assembly process, increasing labor and overhead costs. The required precision tolerance class is crucial. A bearing manufactured to ABEC-1 or similar general industrial tolerances will cost less than one produced to ABEC-5 or ABEC-7 precision tolerances for applications like medical or aerospace equipment. Tighter tolerances require more time on more advanced machinery and more intensive inspection procedures.

The quantity ordered plays a fundamental role in unit cost due to economies of scale. A large production run allows the manufacturer to amortize fixed costs (like tooling setup, programming, and first-article inspection) over many units, drastically reducing the price per bearing. A one-off prototype or a small batch order will have a much higher unit cost. The required certifications can also influence the price. If a bearing must be supplied with material traceability certificates (e.g., 3.1 Mill Certificates), undergo special non-destructive testing (NDT) like magnetic particle inspection, or be produced in a facility with specific certifications (e.g., AS9100 for aerospace), these rigorous documentation and quality assurance processes add administrative and operational expense. Finally, the choice of supplier and their geographic location affects cost. Established brands with a reputation for premium quality and extensive R&D may price their products higher. Furthermore, logistics and import tariffs can add a considerable percentage to the final cost for international purchases. Therefore, the price is a direct reflection of the bearing's size, material, complexity, precision, quantity, and the quality system behind it.

Supplier of Light Load Slewing

For engineers and OEMs seeking a reliable source for high-quality light load slewing bearings, LYRADRIVE stands out as a premier manufacturer and solution provider. The company has established a formidable reputation by mastering the delicate balance between advanced manufacturing hardware and the essential soft power of deep technical expertise and unwavering quality commitment. LYRADRIVE's strength lies in its robust engineering capability, which allows it to not only supply a comprehensive range of standard designs but also to collaborate closely with clients to develop fully customized bearing solutions tailored to specific application requirements, performance criteria, and environmental challenges. This customer-centric approach is supported by a rigorous quality management system that governs every stage of production, from material procurement and forging to precision machining, heat treatment, and final assembly, ensuring every component that leaves its facility meets the highest standards of performance and durability. By offering this powerful combination of technical proficiency, manufacturing excellence, and responsive service, LYRADRIVE has become a trusted partner for industries ranging from robotics and solar energy to medical technology and industrial automation, providing the critical rotational components that drive innovation and efficiency.