Introduction to Two Common Spline Types in Slew Drives

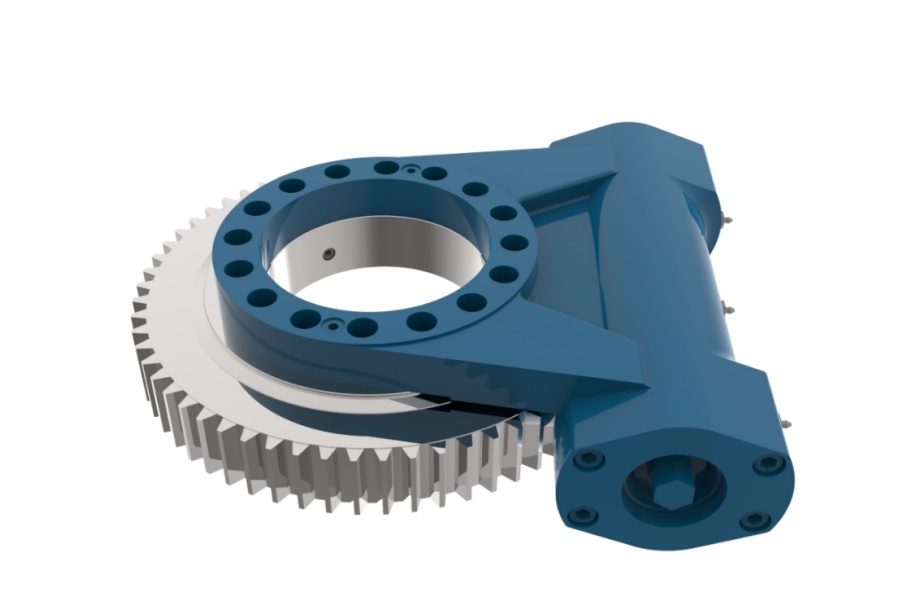

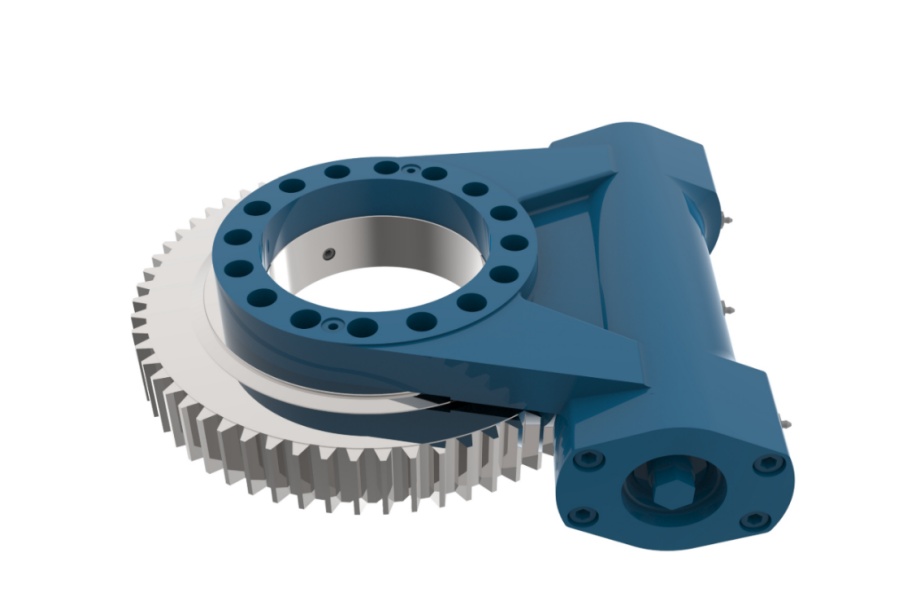

What is a Slew Drive

Slew Drive integrates a slewing ring bearing with a precision gear mechanism within a single housing. This compact rotational system converts high-speed motor input into high-torque output while simultaneously supporting axial, radial, and moment loads. Its unified design eliminates separate drivetrain components, enabling precise 360-degree motion control in applications ranging from solar trackers to industrial cranes.

Critical Spline Configurations for Torque Transmission

Splines provide secure shaft-hub connections while accommodating axial movement. Slew drives primarily utilize these two spline types:

1. Parallel Key Splines

Characterized by straight-sided teeth with uniform radial thickness, these splines feature flank surfaces precisely parallel to the rotational axis. The symmetrical tooth profile terminates in sharp corners at the root diameter.

Manufacturing advantages include approximately 25-30% lower production costs compared to involute alternatives due to simplified machining processes. Inspection is streamlined through basic go/no-go gauge verification. The design permits limited axial sliding movement - typically 0.15mm per 100mm of spline length.

Torque transmission occurs through linear contact along 40-50% of the tooth height. This concentrated engagement generates surface pressures of 120-150 N/mm² during operation. Stress intensification occurs predominantly at the sharp root corners, making these splines susceptible to fatigue fractures under reversing loads. Additional failure modes include fretting corrosion in high-vibration environments and accelerated edge wear during misalignment events. These characteristics make parallel key splines ideal for static or low-cycle applications under 10,000 operating cycles.

2. Involute Splines (30° Pressure Angle Standard)

Featuring curved tooth profiles derived from precise involute geometry, these splines ensure progressive contact engagement with 15-25° operational pressure angles. Three distinct configurations address varying application requirements:

The Flat Root Side Fit variant offers cost-efficient performance for medium-duty applications. Fillet Root Side Fit designs incorporate a full-radius transition between teeth, increasing fatigue strength by approximately 35% through optimized stress distribution. Major Diameter Fit configurations maintain exceptional concentricity with tolerances under 0.02mm through precisely controlled outer diameter dimensions.

Performance advantages include 40-60% greater torque density than parallel splines and inherent self-centering action that maintains angular deviation below 0.05°. The gradual tooth engagement provides natural vibration damping while supporting service life exceeding 500,000 cycles when manufactured to ISO 4156 standards. Contact ratios range from 1.6-2.3 depending on subtype, with fillet root variants achieving the highest surface durability at 280 N/mm² pressure capacity.

Slew Drive Functional Characteristics

Integrated Load Management: Simultaneously handles axial/radial forces and tilting moments

Precision Motion Control: Maintains positioning accuracy within ±0.1°

Compact Power Density: Delivers 3-8x higher torque/weight ratio than conventional drives

Environmental Resilience: IP65-IP69K sealing options available

Maintenance Efficiency: Centralized lubrication points reduce service time

Industrial Applications

Solar Energy: Azimuth/elevation tracking in photovoltaic systems

Construction: Excavator turntables supporting 20-ton loads

Material Handling: Port crane rotation mechanisms

Wind Power: Yaw system positioning in 5MW+ turbines

Aerospace: Satellite antenna aiming mechanisms

Robotics: Heavy-payload welding positioners

Medical: CT scanner gantry rotation systems

Price Determinants

Spline Specification: Involute splines increase cost 20-35% over parallel variants

Precision Requirements: DIN Class 4 tolerances add 15-25% premium

Material Selection: Vacuum-degassed alloy steel increases base price 18-30%

Surface Treatments: Nitriding/TiN coating add 8-15% cost

Sealing Systems: Triple-labyrinth seals vs single lip seals: 12-20% differential

Certifications: Aerospace (AS9100) compliance adds 10-18%

Thermal Management: Integrated cooling features increase cost 7-12%

Quantity Discounts: Volume production reduces unit cost 15-40%

Supplier of Slew Drive

LYRADRIVE engineers high-performance slew drives featuring application-optimized spline connections. Their patented DURASPLINE™ technology enhances torque density by 25% while extending service life beyond industry standards. Utilizing CNC gear profile grinding and 3D metrology verification, LYRADRIVE guarantees spline concentricity within 0.015mm TIR. Custom thermal compensation profiles and corrosion-resistant coatings ensure reliability in extreme environments. With in-house testing facilities validating 100,000+ load cycles, LYRADRIVE delivers certified solutions for critical solar, industrial, and mobile equipment applications worldwide.