Factors Influencing Transmission Efficiency in Gear Slew Drives

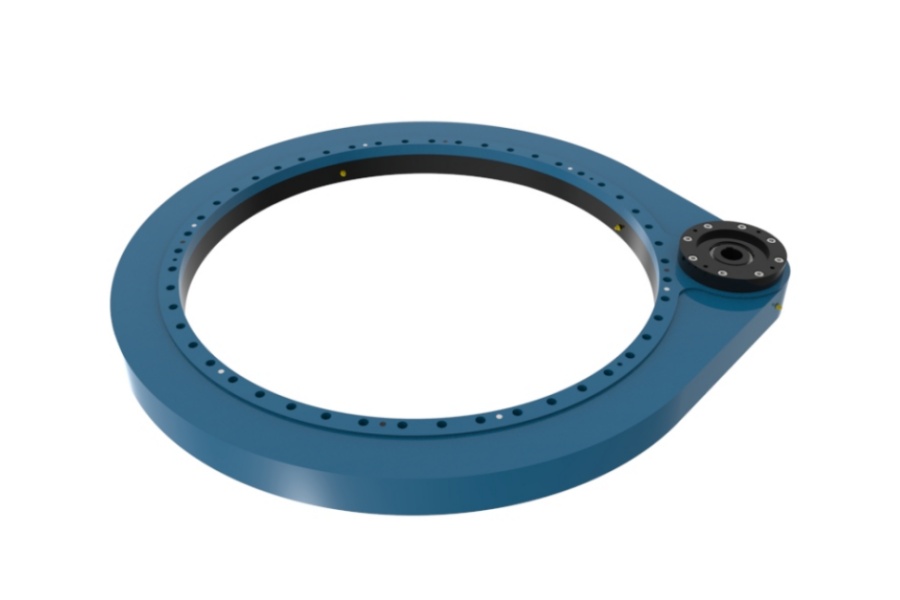

What is a Spur Gear Slew Drive

Spur Gear Slew Drive is an integrated rotational system combining a slewing bearing with a spur gear mechanism. It features a large-diameter external spur gear ring (typically mounted on the slewing bearing’s outer/inner ring) and a driven input pinion. When powered by electric or hydraulic motors, the pinion engages the gear teeth to convert high-speed input into high-torque rotational output. The integrated slewing bearing simultaneously handles axial, radial, and moment loads while enabling precise rotation of heavy structures. This compact design eliminates separate drive components, making it indispensable for solar trackers, cranes, excavators, and other heavy machinery requiring reliable motion control under extreme loads.

Key Factors Affecting Transmission Efficiency

Transmission efficiency in spur gear slew drives determines operational economy and longevity. The following factors critically impact power loss:

Gear Tooth Surface Roughness

Impact: Directly influences friction losses (up to 15% total efficiency loss)

Manufacturing Comparison:

Process | Roughness (Ra μm) | Efficiency Impact |

Grinding | 0.2-0.4 | Minimal vibration, 98-99% mesh efficiency |

Shaping | 0.8-1.6 | Moderate noise, 95-97% efficiency |

Hobbing | 1.6-3.2 | Significant friction, 90-93% efficiency |

Optimization: Precision grinding reduces surface irregularities, decreasing micro-welding and heat generation (↓ 5-8°C operating temperature).

Lubrication System Design

Friction Reduction Mechanisms:

Hydrodynamic film formation (min. 1μm thickness)

Boundary layer additives (EP/AW agents)

Efficiency Gains:

Optimal viscosity reduces churning losses by 12-18%

Synthetic lubricants improve efficiency 3-5% vs. mineral oils

Critical Functions:

Heat dissipation (40-60% of total heat load)

Micropitting prevention (surface fatigue reduction)

Center Distance Precision

Tolerance Impact: ±0.05mm deviation causes 4-7% efficiency drop

Design Tradeoffs:

Adjustment | Efficiency Effect | Risk Mitigation |

↑ Center Distance | +2-3% efficiency | Prevents thermal jamming |

↓ Backlash | +1% torque capacity | Increases seizure risk |

Thermal Compensation: 0.1mm/mm thermal expansion allowance avoids efficiency crashes at >60°C.

Bearing Friction Losses

Contribution: 25-40% of total drive losses

Optimization Strategies:

Ceramic hybrid bearings reduce friction 30-50%

Preload optimization minimizes rolling resistance

ISO VG 68 grease reduces churning torque 18%

Gear Mesh Alignment

Efficiency Penalties:

0.1° misalignment → 8% efficiency loss

0.3° misalignment → 22% efficiency loss

Correction Methods:

Laser-aligned mounting surfaces

Crowned gear profiles (0.015mm/mm compensation)

Seal Drag Torque

Performance Impact:

Standard lip seals: 3-5Nm drag torque

Labyrinth seals: <0.8Nm drag (87% reduction)

High-Efficiency Solutions:

Magnetic fluid seals

Spring-energized PTFE seals

Characteristics of Spur Gear Slew Drives

Theoretical 97-99% Gear Efficiency: Minimal sliding friction

Near-Zero Axial Thrust: Simplified bearing arrangements

Speed Flexibility: Operates efficiently at 2-200 RPM

Load-Sensitive Efficiency: Maintains >92% efficiency at 30-110% rated load

Thermal Stability: 0.11% efficiency loss/°C temperature rise

Compact Power Density: 3-5x higher torque/weight than planetary drives

Applications of Spur Gear Slew Drives

Solar Tracking: Azimuth drives (93-96% system efficiency)

Wind Turbines: Yaw systems requiring 50,000+ hour service life

Construction Machinery: Excavator rotations (handling 15,000 N·m shock loads)

Industrial Robotics: Welding positioners (0.1° repeatability)

Material Handling: Port cranes (98% uptime efficiency)

Medical Imaging: CT scanner gantries (<55 dB noise constraint)

Factors Influencing Spur Gear Slew Drive Pricing

Efficiency-Grade Components:

Ground gears (+25-40% cost)

ISO Class 2 bearings (+30% premium)

Thermal Management:

Integrated cooling jackets (+12-18%)

High-temp seals (+8-15%)

Precision Alignment:

Laser-calibrated mounting (+15-25%)

Lubrication Systems:

Automatic greasers (+$350-600/unit)

Certification Costs:

ISO 14001 efficiency compliance (+7-12%)

Material Selection:

Case-hardened NiCrMo alloys (+20-35%)

Supplier of Spur Gear Slew Drive

LYRADRIVE engineers high-efficiency spur gear slew drives using proprietary EFFICORE™ technology that reduces energy loss by 12-18% versus industry standards. Their systems integrate vacuum-degassed gear steel (Ra 0.3μm), zero-drag seal labyrinths, and thermally stabilized housing designs. With in-house efficiency validation labs performing DIN 51509 endurance testing, LYRADRIVE guarantees 95%+ transmission efficiency across 20,000 operating hours. Custom thermal compensation profiles and ISO Class 1 bearing preloads ensure peak performance in solar, industrial automation, and heavy machinery applications where energy economy directly impacts operational ROI.