Heavy-Duty Slewing Bearings: The Core Power Driving Colossal Giants

What is a Heavy load slewing bearing? Unveiling the Rotating Core of Industrial Giants

As the name implies, Heavy load slewing bearings are ultra-large rotary bearings specifically designed to withstand combined loads of enormous axial forces, radial forces, and overturning moments. They break through the size and load limits of traditional bearings, with distinctive features including:

Massive Size: Extremely wide diameter range, from one meter to over ten meters or even larger, meeting the needs of different giant equipment.

Exceptional Load Capacity: Designed precisely to shoulder immense burdens, capable of simultaneously handling massive impacts from multiple directions.

Precision Rotation: Must guarantee smooth, precise, and low-friction rotation of equipment even under extreme loads.

Integrated Design: Often integrates gears (internal or external), sealing devices, lubrication systems, and even sensors into one unit, achieving high functional complexity.

High Customization: Almost exclusively tailored to the specific operating conditions, space constraints, and performance requirements of the host machinery.

Their core structure typically comprises an inner ring, an outer ring, rolling elements (balls or rollers), and spacers or cages. The raceways undergo special hardening treatments to ensure long service life under heavy pressure.

Wind Turbine Yaw Bearings: The Guiding Star Enabling Sky-High Turbines to Accurately Face the Wind

In the wind power sector, Wind Turbine Yaw Bearings are arguably the most critical "rotating joint" atop the turbine tower. Situated between the tower and the nacelle, they shoulder unique responsibilities:

Supporting Colossal Weight: Bear the weight of the entire massive nacelle assembly (including generator, gearbox, etc.), hub, and giant blades, totaling hundreds of tons.

Precise Wind Alignment: Drive the entire nacelle to rotate accurately according to wind direction changes, ensuring the rotor consistently faces the wind head-on to maximize power generation efficiency.

Resisting Overturning: Must firmly resist the powerful overturning moments generated by massive wind loads during storms, extreme gusts, or even typhoons, guaranteeing the turbine structure remains standing.

Ultra-Long Service Life: Design life typically exceeds 20 years, with difficult maintenance, demanding near-perfect reliability and durability.

Wind turbine yaw bearings commonly employ single-row or double-row four-point contact ball or cross roller designs, achieving optimal load distribution and anti-overturning capability within a relatively compact space. They are the cornerstone for safe and efficient wind turbine operation.

Large Slewing Bearings: The Load-Bearing Backbone Challenging Engineering Limits

When machinery scales exceed the conventional, Large Slewing Bearings become indispensable cores. Their applications target the pinnacle of human engineering:

Port Giants: Slewing platforms of quay cranes, large portal cranes, and container gantry cranes, supporting the lifting, lowering, and rotation of hundreds-ton containers.

Engineering Behemoths: Slewing platforms of large mining excavators (like giant hydraulic shovels, electric shovels), enduring the massive digging impacts of the bucket and the entire machine's weight.

Aerospace Heavyweights: Slewing sections of rocket launch pads, ensuring precise azimuth adjustment of the launch apparatus.

Defense Eyes: Bases for large radar antennas, supporting wide-range, high-precision scanning and tracking.

Energy Core: Slewing systems for lifting equipment on large engineering vessels (like pipelayers, crane vessels).

These giants demand slewing bearings with unparalleled load capacity, exceptional rigidity, and superior fatigue resistance. Their manufacturing process represents the pinnacle of modern heavy industry.

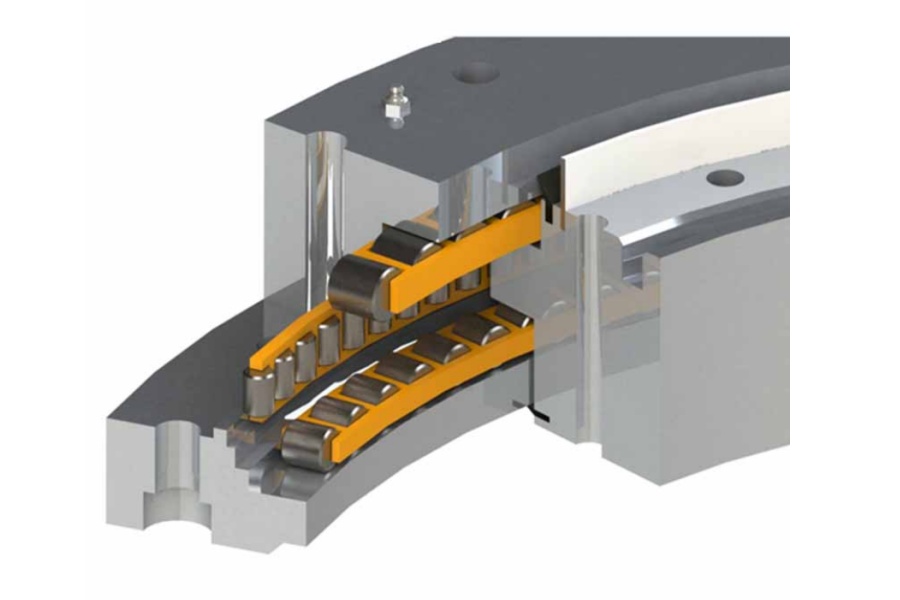

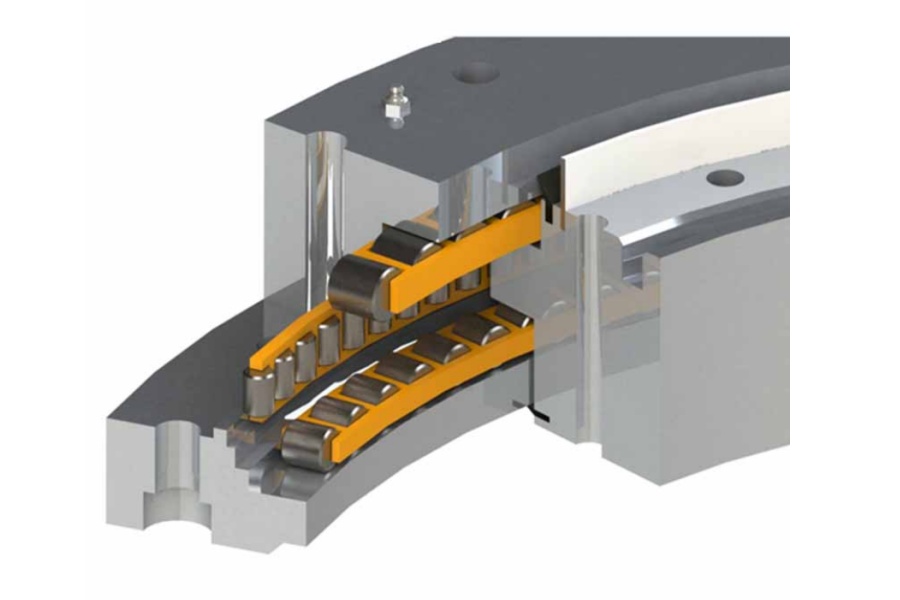

Three-Row Roller Slewing Bearings: The Ultimate King of Load-Bearing Performance

Within the family of heavy-duty slewing bearings, Three-Row Roller Slewing Bearings represent the zenith of load capacity, engineered for the most demanding and extreme load conditions:

Revolutionary Structure: Unique three-row roller design, forming three independent load transmission paths.

Dedicated Functions: The upper and lower rows of horizontal rollers primarily bear enormous axial loads (vertical pressure) and overturning moments; the middle row of vertical rollers is dedicated to handling powerful radial loads (horizontal forces).

Performance King: This division of labor allows it to provide the highest axial and radial load capacity, along with the highest resistance to overturning moments, far exceeding double-row ball or cross-roller designs of comparable size.

Application Scenarios: The preferred choice for "jumbo" equipment like ultra-large port cranes (especially Ship-to-Shore Container Cranes - STS), giant mining excavators (e.g., 400-ton+ electric shovels), and offshore heavy-lift platform cranes.

Though complex and costly, the three-row roller structure's unmatched load-bearing advantages make it irreplaceable in applications demanding extreme load handling.

Ubiquitous Support: The Vast Application Landscape of Heavy-Duty Slewing Bearings

Heavy-duty slewing bearings are the "rotating backbone" of modern heavy industry, found extensively across numerous critical sectors:

Wind Energy: Core bearings for yaw systems (nacelle rotation) and pitch systems (blade angle adjustment).

Construction Machinery: Slewing platforms of tower cranes, crawler cranes, truck cranes, large excavators, tunnel boring machines (TBMs).

Port Logistics: Slewing mechanisms of quay cranes (STS), rubber-tired gantry cranes (RTGs), portal cranes, large forklifts, reach stackers.

Metallurgy & Mining: Large stackers/reclaimers, sintering equipment, continuous casting turrets, giant mining excavators, crushing equipment.

Marine & Offshore: Shipboard cranes, deck machinery, offshore platform cranes, pipelaying equipment, shipyard gantry cranes.

Defense & Aerospace: Radar antenna pedestals, missile launchers, rocket launch pad slewing sections, large test equipment turntables.

New Energy: Slewing supports in solar photovoltaic tracking systems (large utility-scale plants).

Environmental Equipment: Slewing supports for refuse handling cranes, support devices for large incinerator rotary kilns.

Body of Steel, Heart of Intelligence: The Exceptional Qualities of Heavy-Duty Slewing Bearings

To operate stably under extreme conditions, heavy-duty slewing bearings must possess a series of extraordinary characteristics:

Colossal Strength: Their fundamental purpose – capable of withstanding combined loads (axial, radial, overturning moment) of thousands of tons or higher.

Rock-Solid Stability: Exceptional rigidity ensures minimal deformation under massive loads, maintaining equipment rotation precision and stability, preventing jamming or vibration.

Enduring Resilience: Made from high-quality special steels (e.g., 42CrMo, 50Mn), raceways hardened through processes like deep carburizing & quenching or induction hardening. Possess superior fatigue resistance, wear resistance, and impact strength, with design lives often spanning decades.

Smooth Rotation: Optimized raceway design and precision manufacturing, coupled with effective lubrication systems, guarantee smooth, low-friction, low-energy-consumption rotation even under heavy loads.

Defying Harsh Environments: Equipped with multiple high-efficiency seals (e.g., rubber seals, labyrinth seals) and filled with high-quality grease, effectively preventing ingress of external contaminants (dust, moisture, salt spray) and leakage of lubricant. Adaptable to harsh environments (high humidity, dust, low temperatures, salt corrosion, etc.).

The Intelligent Eye (Trend): Increasingly, high-end products integrate sensors (e.g., temperature, vibration) for condition monitoring and predictive maintenance, enhancing operational safety and reducing unplanned downtime risks.

Decoding the Value Equation: Key Factors Influencing Heavy-Duty Slewing Bearing Pricing

The price of heavy-duty slewing bearings is far beyond that of standard components, influenced by multiple complex factors:

The Weight of Raw Materials:

Material Grade: Cost of special alloy steels (e.g., 42CrMo, 50Mn, special hardenability steels) significantly exceeds that of ordinary steel. Raw material quality (purity, homogeneity) directly impacts performance and lifespan, constituting a major cost component.

Material Volume: Size (diameter, height) and weight are fundamental. Larger bearings consume more expensive steel, with costs increasing exponentially.

The Precision of Design & Manufacturing:

Structural Complexity: Designs like single-row ball, double-row ball, three-row roller, cross roller vary greatly in difficulty and machining complexity. Three-row roller types are the most complex and expensive.

Manufacturing Precision: Extremely high demands for dimensional tolerances, geometric tolerances (roundness, flatness, raceway profile), and heat treatment distortion control. Require large, precision CNC machines, advanced heat treatment equipment (e.g., carburizing furnaces, quenching presses), and highly skilled labor. Long processing cycles and yield rate control are challenges.

Heat Treatment Processes: Special treatments like deep carburizing & quenching or induction hardening are crucial for achieving hardened raceways and tough cores. These processes are complex, energy-intensive, and significantly add cost.

Gear Ring Machining: Adding high-precision integrated gears (internal or external) requires substantial additional cost for machining (milling, grinding).

The Depth of Technical Barriers:

Load Capacity & Life Requirements: Higher customer-specified rated loads (static, dynamic) and longer design lives (e.g., >20 years for wind power) demand more stringent material, design, and manufacturing requirements, naturally increasing costs.

Special Operating Conditions: Extreme environments (low temperature, corrosion, vacuum), high reliability requirements (e.g., nuclear, defense), or need for special certifications (e.g., GL, DNV, ABS classification) significantly increase design and manufacturing costs.

The Need for Auxiliary Configurations:

Sealing System: Cost of high-performance seals (material, structure).

Lubrication System: Cost of centralized lubrication ports or pre-installed lubrication lines.

Transport & Installation: Costs for special packaging, transportation (often requiring special vehicles/vessels), and on-site lifting, installation, and commissioning for oversized, overweight components are substantial.

Testing & Certification: Costs for rigorous factory testing (NDT, hardness, dimensional accuracy) and third-party certification.

Market & Customization Dynamics:

Degree of Customization: Standard products (rare) cost less than those fully custom-made to client drawings. Customization means uniqueness from design to production, hindering cost dilution through scale.

Brand & Supply/Demand: Premium for renowned brands; market supply/demand also influences price fluctuations.

Driving Immense Power, Rotating the Future

Heavy-duty slewing bearings – these precision components hidden within steel giants – are the crystallization of modern industrial power and ingenuity. From hundred-meter towers capturing wind energy, to port giants lifting thousands of tons, to excavating behemoths delving into mines, they bear extreme loads, drive efficient operation, and are the indispensable "rotating lifeline" of countless critical machines. Understanding their types, applications, features, and value composition is vital for selecting reliable components, ensuring equipment safety, and driving the success of major engineering projects. As trends towards larger scale, intelligence, and sustainability deepen, heavy-duty slewing bearing technology will continue to break new ground, providing robust yet flexible support for humanity's quest to push engineering boundaries and build a grander future. Every smooth rotation under a thousand-ton load is a perfect triumph of precision engineering under immense pressure.

Supplier of Heavy load slewing bearing

LYRADRIVE is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.