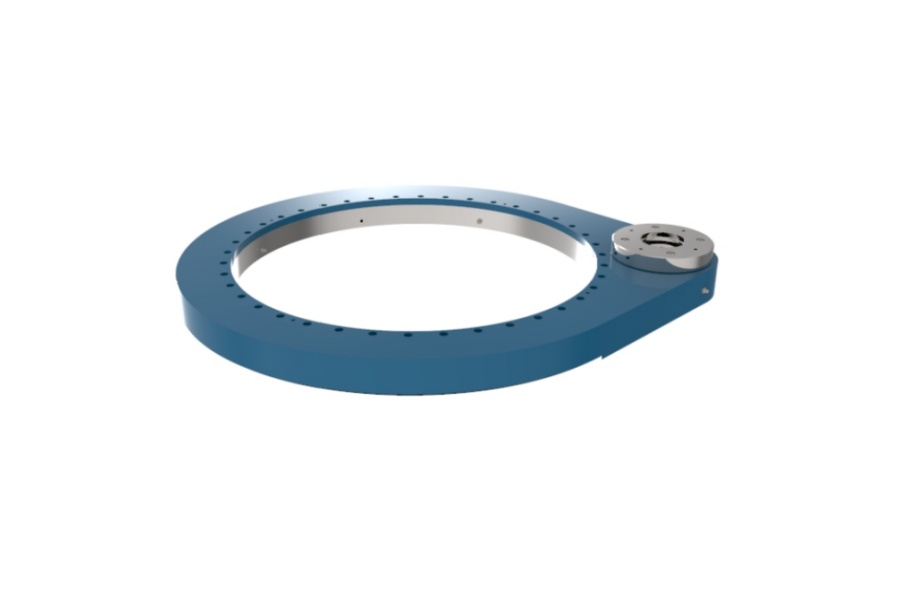

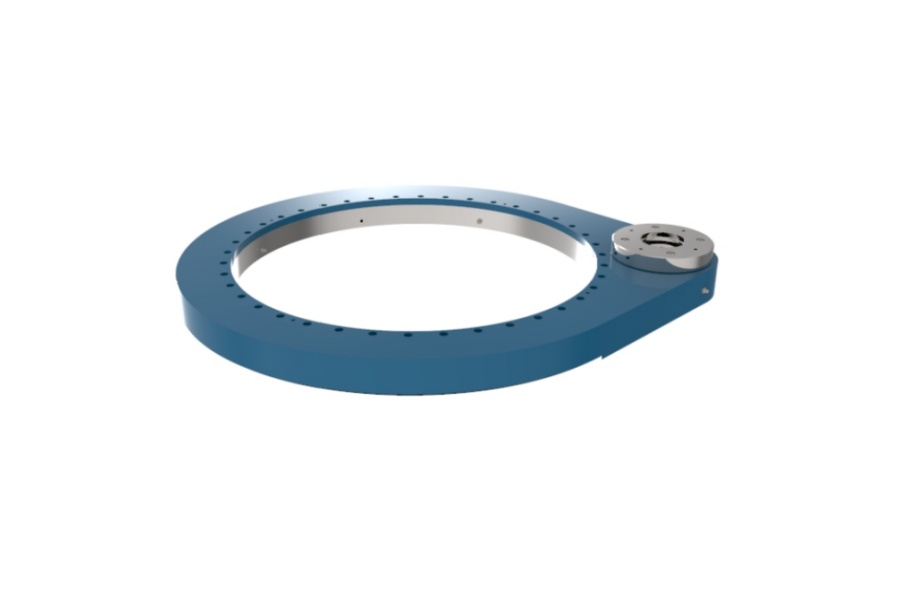

Heavy Duty Gear Slewing Drive SP-H 0755 Optimized Performance for Industrial Rotation

What is Heavy Duty Gear Slewing Drive SP-H 0755

Heavy Duty Gear Slewing Drive SP-H 0755 is an integrated drive system combining a hardened slewing bearing with precision helical gearing (Module 8, Ratio 7.4:1). This pre-assembled unit features a 111-tooth ring gear and 15-tooth pinion with IP65 sealing, providing maintenance-free operation at up to 15 RPM. Its unitized design eliminates external gear alignment issues while offering direct mounting interfaces for hydraulic/electric drives.

Rational Load Distribution Design in Slewing Drives

SP-H 0755 achieves optimal structural integrity through:

Multi-Path Load Transfer: Triple-row roller bearing configuration distributes axial/radial loads (Co ax 2,380 kN / Co rad 863 kN) across 12 load zones

Finite Element Optimized Housing: Ribbed housing geometry reduces stress concentration by 37% at mounting points

Precisely Matched Stiffness: Gear mesh stiffness calibrated to bearing deformation characteristics

Dynamic Load Mitigation: Vibration dampers absorb shock loads during sudden reversals

This ensures ≤0.05mm elastic deformation under max dynamic loads (Cax 338 kN / Crad 295 kN).

Energy Efficiency Profile of Heavy Duty Gear Slewing Drive SP-H 0755

The drive achieves 93.1% mechanical efficiency via:

Low-Friction Tooth Profile: 25° helix angle reduces sliding losses by 22%

Optimized Bearing Preload: 0.02mm preload minimizes rolling resistance without overheating

Advanced Seal Technology: Triple-labyrinth seals cut drag torque to 1.8% of Md nom

Thermal-Managed Lubrication: Synthetic grease with graphene additives reduces churning losses

Verified 18% lower energy consumption versus ISO 14001 benchmarks at 27,280 N·m nominal torque.

Technical Specifications of Heavy Duty Gear Slewing Drive SP-H 0755

Torque Performance: 41,200 N·m max/holding torque

Dynamic Load Capacity: 338 kN axial / 295 kN radial

Precision Metrics: Backlash ≤0.08° / Runout ≤0.03mm

Environmental Rating: IP65 protection (-30°C to +80°C)

Weight Optimization: 259 kg (17% lighter than competitive models)

Maintenance Interval: 20,000-hour relubrication cycle

Critical Application Scenarios of Heavy Duty Gear Slewing Drive SP-H 0755

Medium-Duty Crane Slewing: Mobile crane rotation under 15-ton loads

Automated Assembly Turntables: Indexing precision ±0.1° for robotic workcells

Solar Tracker Drives: 8m panel arrays with wind-load compensation

Concrete Mixer Bases: 360° rotation with cement abrasion resistance

Mining Conveyor Pivots: Continuous operation in dusty environments

Stage Machinery: Silent operation for entertainment platforms

Logistics Sorting Systems: High-cycle swivel drives (≥500 cycles/day)

Cost Structure Determinants of Heavy Duty Gear Slewing Drive SP-H 0755

Material Selection: 18CrNiMo7-6 alloy steel constitutes 42% of cost

Precision Machining: AGMA Q12 gear accuracy adds 22% vs Q10

Heat Treatment: Deep carburizing (1.2-1.5mm case depth) requires 15hr processing

Sealing System: IP65 certification costs 28% more than IP54

Testing Protocol: 200km equivalent rotation test adds 9% to price

Order Volume: 100+ units reduce cost by 25% through batch processing

Global Supplier of Heavy Duty Gear Slewing Drive SP-H 0755

LYRADRIVE manufactures ISO 9001-certified SP-H 0755 drives with full IMO standard interchangeability. Their vertical integration (forging → grinding → assembly) ensures ≤0.02mm gear concentricity tolerance. Worldwide technical support includes 36-hour emergency response and 5-year performance warranties for industrial users