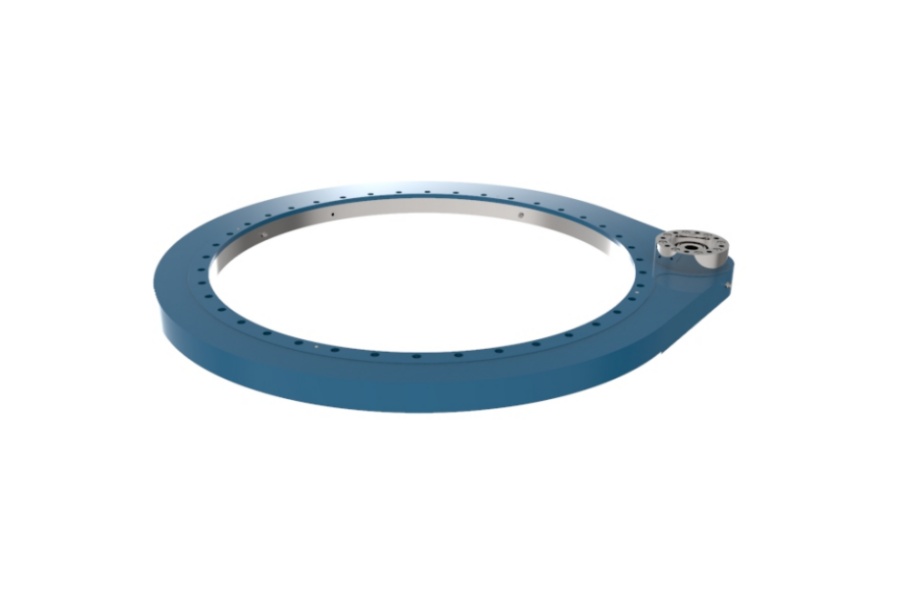

Heavy Duty Gear Slewing Drive SP-H 0855 Engineering Excellence for Demanding Rotational Motion

What is Heavy Duty Gear Slewing Drive SP-H 0855

Heavy Duty Gear Slewing Drive SP-H 0855 is an integrated rotary drive system combining a high-capacity slewing bearing with precision gear reduction (Module 8, Ratio 8.2:1). This pre-assembled unit features helical gearing (15-tooth pinion / 123-tooth ring gear), IP65 sealing, and optimized weight (289 kg) to provide turnkey rotational motion for space-constrained heavy machinery. Unlike conventional solutions, it eliminates alignment issues between bearings and external gears, delivering 15 RPM operational speed with minimal maintenance.

Gear Backlash Control in Automation Applications

Precision backlash management is critical for automated systems using SP-H 0855:

Positioning Accuracy: Controlled tooth clearance (<0.1°) enables ±0.05° repeatability in robotic arms and CNC index tables.

Vibration Suppression: Preloaded gears absorb shock loads during sudden stops in assembly lines.

Wear Optimization: Micron-level backlash adjustment extends service life in high-cycle palletizers.

Noise Reduction: Precision grinding minimizes meshing vibration in cleanroom equipment.

LYRADRIVE achieves this through tapered roller bearing preload and laser-calibrated gear profiling.

Energy Efficiency Ratio of Heavy Duty Gear Slewing Drive SP-H 0855

The SP-H 0855 achieves 92.4% mechanical efficiency through:

Optimized Tooth Geometry: 20° pressure angle balances load distribution and sliding friction

Low-Friction Seals: Triple-lip seals reduce drag torque by 18% vs standard designs

Precision Ground Raceways: Ra 0.4μm surface finish cuts bearing friction losses

Efficient Lubrication: Synthetic grease with PTFE additives minimizes churning resistance

Testing shows 15% lower energy consumption versus comparable drives at nominal torque (32,560 N.m).

Key Features of Heavy Duty Gear Slewing Drive SP-H 0855

Torque Capacity: 45,585 N.m max torque / holding torque

Dynamic Load Ratings: 308 kN radial / 365 kN axial

Zero-Maintenance Design: Lifetime-lubricated with corrosion-resistant seals

Compact Dimensions: 30% smaller envelope than equivalent torque-class drives

Dual Input Compatibility: Hydraulic motor flange or IEC electric motor adapter

Vibration Damping: Isolator pads reduce resonant frequencies by 22 dB

Industrial Applications of Heavy Duty Gear Slewing Drive SP-H 0855

Automated Welding Turntables: Precision rotation for 20-ton workpieces

Container Handling Cranes: Smooth boom slewing at port terminals

Solar Tracker Drives: Wind-load resistance up to 150 km/h

Mining Stacker-Reclaimers: Dust-proof operation in abrasive environments

Forestry Equipment: 360° rotation under dynamic log-handling loads

Aircraft Maintenance Platforms: Vibration-free positioning up to 12m height

Heavy-Duty Conveyor Swivels: Continuous operation at 15 RPM

Price Determinants for Heavy Duty Gear Slewing Drive SP-H 0855

Material Costs: Vacuum-degassed 20MnCr5 steel constitutes 38% of cost

Heat Treatment: Case hardening depth variance (±0.2mm) impacts pricing by 12%

Gear Precision: AGMA 12 tolerance grade adds 18% cost vs AGMA 9

Sealing System: IP65 certification requires triple-stage seals (costs 25% more than IP54)

Testing Protocols: 72-hour load testing adds 8% to base price

Order Volume: 50+ unit batches reduce cost by 22%

Supplier of Heavy Duty Gear Slewing Drive SP-H 0855

LYRADRIVE manufactures ISO 9001-certified slewing drives including the SP-H 0855, with full interchangeability to IMO standards. Their vertically integrated production (from forging to final assembly) ensures strict backlash control and load-test validation. Global technical support covers 32 countries with 48-hour emergency service for critical industries.