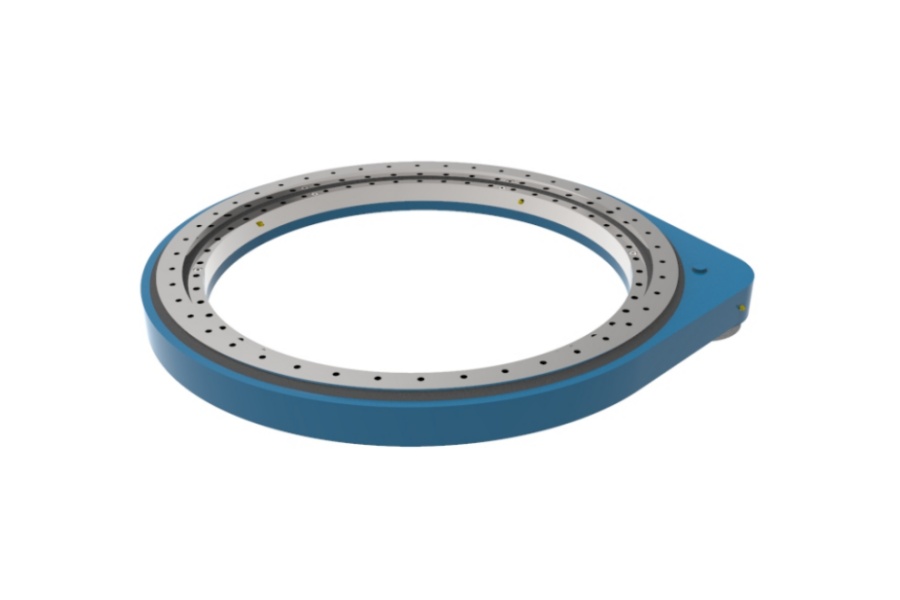

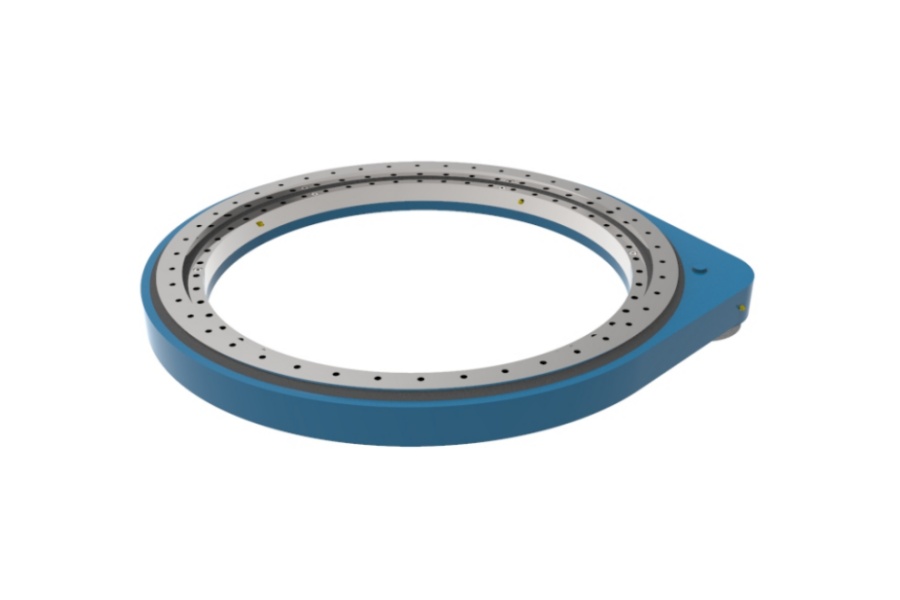

Heavy Duty Gear Slewing Drive SP-H 0955 Power Precision and Reliability for Demanding Applications

What is Heavy Duty Gear Slewing Drive SP-H 0955

Heavy Duty Gear Slewing Drive SP-H 0955 is a sophisticated, integrated rotary drive system specifically designed for heavy-duty applications requiring high torque transmission, precise rotational control, and robust structural support. It transcends the function of a simple bearing by incorporating a precision gear reduction mechanism directly within the unit. At its core lies a high-capacity slewing ring bearing, meticulously engineered with either spur or helical gearing, coupled with a precisely meshed pinion gear. This integrated design delivers a significant gear reduction ratio (i=9 for the SP-H 0955), amplifying input torque while reducing output speed. The unit is fully sealed (typically achieving IP65 protection), pre-lubricated, and arrives as a ready-to-install assembly, drastically simplifying mechanical design, reducing installation complexity, and minimizing ongoing maintenance requirements compared to traditional separate bearing and drive train setups. It's particularly suited for applications where space constraints exist alongside demanding load and precision requirements.

Impact of Gear Radial Runout on Slewing Drive Performance

Gear radial runout, essentially the deviation of the gear tooth profile from its ideal circular path relative to the rotational axis, is a critical quality parameter with profound implications for slewing drive performance and longevity. In a Heavy Duty Gear Slewing Drive like the SP-H 0955, excessive radial runout can lead to several detrimental effects:

Increased Noise and Vibration: Runout disrupts the smooth meshing of the pinion and ring gear teeth. This irregular contact generates impact loads during engagement and disengagement, manifesting as loud, often objectionable noise and significant vibration throughout the connected structure. This not only creates an unpleasant work environment but also transmits damaging forces to other components.

Accelerated Wear and Premature Failure: The uneven loading caused by runout concentrates stress on specific sections of the gear teeth. This localized stress exceeds the design limits, leading to rapid surface fatigue, pitting, scoring, and ultimately, tooth breakage. The lifespan of the entire slewing drive unit is drastically reduced.

Reduced Positioning Accuracy and Repeatability: Precision applications, such as automated machinery or crane positioning, rely on consistent angular movement. Runout introduces backlash variations and irregular rotation, making it difficult to achieve and maintain precise target positions, negatively impacting operational accuracy and repeatability.

Elevated Operating Temperatures: The friction generated by irregular meshing and increased sliding action due to runout converts mechanical energy into heat more efficiently. This leads to higher operating temperatures within the gearbox, which can degrade lubricant properties, accelerate oxidation, and further exacerbate wear mechanisms.

Increased Power Consumption: Overcoming the friction and impacts caused by runout requires more energy input. This inefficiency translates directly into higher operating costs over the drive's lifetime.

Therefore, minimizing radial runout through precision manufacturing and strict quality control, as achieved in the SP-H 0955, is paramount for ensuring smooth, quiet, efficient, and long-lasting operation in demanding slewing applications.

Energy Efficiency Ratio of Heavy Duty Gear Slewing Drive SP-H 0955

While slewing drives are primarily evaluated on their torque capacity and load ratings, energy efficiency is an increasingly crucial factor impacting operational costs and environmental footprint. The Heavy Duty Gear Slewing Drive SP-H 0955 incorporates several design features contributing to a favorable energy efficiency ratio (EER), effectively maximizing output performance relative to input power:

Precision Gearing: High-quality gear manufacturing processes ensure accurate tooth profiles, minimal profile errors, and controlled surface finishes. This precision minimizes sliding friction and meshing losses during power transmission, a significant source of energy waste in power transmission systems. The helical gearing option (if applicable) offers smoother engagement compared to spur gears, further reducing friction and noise.

Optimized Gear Geometry: The specific gear design (module, pressure angle, helix angle) influences contact patterns and load distribution. Optimized geometry ensures that loads are spread effectively across the tooth faces, reducing localized stress peaks that contribute to friction losses. The gear ratio (i=9) allows smaller, more efficient motors or hydraulic systems to generate the high output torque (Md nom = 35,380 N.m, Md max = 50,291 N.m) required.

High-Quality Bearing Design: The integral slewing bearing utilizes precision-ground raceways and high-quality rolling elements (balls or rollers). This minimizes rolling friction within the bearing itself, which is a direct consumer of input power. Efficient bearing design contributes significantly to the overall system efficiency.

Advanced Sealing with Low Friction: While essential for protection (IP65 rating), seals can be a source of parasitic drag. The SP-H 0955 employs advanced sealing solutions designed to effectively exclude contaminants while minimizing the friction drag force they exert on rotating components.

Optimized Lubrication: The correct type and quantity of high-performance grease reduce friction between meshing gears and rolling elements without causing excessive churning losses. The sealed design ensures lubrication remains effective for extended periods, maintaining low friction operation.

High Torque Density: The SP-H 0955 achieves exceptional torque output (Max Torque: 50,291 N.m) relative to its weight (318 kg). This high torque density means less material is used to transmit a given torque, implying lower inertial losses during acceleration/deceleration and overall less mass to be driven, contributing indirectly to energy savings in dynamic applications.

Compared to systems built from separate components (motor, gearbox, bearing), the integrated design of the SP-H 0955 inherently reduces losses from couplings, misalignments, and inefficient power transmission paths. This holistic approach results in a slewing drive that delivers its impressive power capabilities efficiently, translating to lower energy consumption and operating costs over its long service life.

Key Features of Heavy Duty Gear Slewing Drive SP-H 0955

The SP-H 0955 distinguishes itself through a combination of robust engineering and intelligent design tailored for maximum performance and reliability in harsh conditions:

Exceptional Load Capacity: Engineered to handle extreme forces simultaneously. It boasts a radial static load capacity (Co rad) of 1,095 kN, an axial static load capacity (Co ax) of 2,898 kN, dynamic radial load (Crad) of 320 kN, and dynamic axial load (Cax) of 382 kN. This multi-directional strength is fundamental for heavy machinery stability.

High Torque Transmission: Delivers a substantial nominal torque (Md nom) of 35,380 N.m and a maximum torque (Md max) / maximum holding torque (Mh) of 50,291 N.m, enabling it to drive large, heavily loaded platforms against significant resistance.

Precision Gear Design: Features a module (M) of 8 mm with a ring gear (Z2) of 135 teeth and a pinion (Z1) of 15 teeth, achieving a gear ratio (i) of 9:1. Precision machining ensures low backlash, smooth operation, and efficient power transfer.

Integrated, Unitized Design: Combines the slewing bearing, precision gearing, seals, and often mounting features into a single, pre-assembled, and pre-lubricated unit. This drastically simplifies system design, installation, and alignment procedures.

Superior Sealing (IP65): Employs advanced sealing technology to achieve IP65 ingress protection. This effectively seals out dust, dirt, and water jets, safeguarding internal gears and bearings from contamination, a primary cause of premature wear and failure. This extends maintenance intervals significantly.

Robust Construction: Manufactured from high-strength alloy steels and subjected to rigorous heat treatment processes to ensure components possess the necessary hardness, toughness, and fatigue resistance for demanding duty cycles.

Optimized Compactness & Weight: Despite its immense capabilities, the design focuses on space efficiency and weight optimization (318 kg), making it suitable for applications where installation space is constrained without compromising structural integrity.

Flexible Drive Options: Designed to accept input from various prime movers, including electric motors (geared or direct drive) and hydraulic motors, providing adaptability to different power systems and application needs.

High Speed Capability: Supports operational speeds up to 15 RPM, suitable for applications requiring faster slewing motions alongside high load capacity.

Reduced Maintenance: The unitized, sealed design significantly extends the period between required maintenance interventions compared to open gear systems or separate bearing/drive arrangements, lowering total cost of ownership.

Primary Applications of Heavy Duty Gear Slewing Drive SP-H 0955

The SP-H 0955's blend of high load capacity, torque, precision, and ruggedness makes it indispensable across numerous demanding industrial sectors:

Construction Cranes: Tower cranes, mobile cranes, and crawler cranes rely heavily on slewing drives for the smooth, controlled, and powerful rotation of the boom and upper works under full load. The SP-H 0955 provides the necessary torque, stability, and reliability for safe lifting operations.

Material Handling Equipment: Found in heavy-duty stacker reclaimers, ship-to-shore gantry cranes, rail-mounted gantry cranes (RMGs), and container handling equipment, enabling precise positioning of large loads in ports, rail terminals, and bulk handling yards.

Heavy-Duty Turntables and Indexing Tables: Used in manufacturing, welding automation, assembly lines, and heavy-duty positioning systems where large platforms or workpieces need to be rotated accurately and held firmly in position under significant load.

Solar Tracking Systems (Utility Scale): For large-scale solar farms using single-axis or dual-axis trackers, especially in challenging environments or for larger panel arrays requiring robust drives capable of handling wind loads and providing precise sun tracking.

Wind Turbine Components: Used in yaw drives for smaller turbines or potentially in blade pitch control mechanisms, although specific designs vary. Their robustness is valuable in nacelle applications.

Mining & Mineral Processing Equipment: Applied in large bucket wheel excavators, stackers, reclaimers, tunnel boring machine (TBM) segments, and rotary ore sampling equipment where high loads, dust, and moisture are prevalent.

Forestry Machinery: Integrated into harvester and forwarder cranes for precise and powerful rotation of the boom during tree felling and log handling.

Defense & Aerospace: Used in radar platforms, missile launcher turntables, and ground support equipment requiring precise, stable rotation under heavy loads.

Heavy Transport Systems: Employed in self-propelled modular transporters (SPMTs) for rotating heavy modules during complex maneuvers or positioning.

Industrial Automation: For large robotic arms, palletizing/depalletizing systems, and specialized machinery requiring robust and precise rotary motion in demanding factory environments.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0955 Pricing

The price of a high-performance component like the SP-H 0955 is determined by a complex interplay of factors reflecting its engineering, materials, and manufacturing demands:

Raw Material Costs & Quality: High-grade alloy steels required for gears, bearings, and housings represent a significant portion of the cost. Fluctuations in global steel prices directly impact the base cost. The specific alloy grades and their required certifications (e.g., for traceability, impact toughness) also affect price.

Manufacturing Complexity & Precision: Producing large, hardened, precision-ground gears (Module 8, 135 teeth) and high-precision slewing bearing raceways requires specialized, expensive machinery (large gear hobbing/grinding machines, large turning centers, bearing grinders) and highly skilled labor. The tolerance levels required to achieve low runout, precise tooth profiles, and smooth bearing operation are extremely tight, demanding significant process control and inspection.

Heat Treatment Processes: Critical components undergo complex heat treatment cycles (carburizing, hardening, tempering) to achieve the necessary surface hardness for wear resistance and core toughness for impact resistance. These processes are energy-intensive and require precise control, adding considerable cost.

Quality Control & Testing: Rigorous quality control throughout the manufacturing process, including material certifications, dimensional inspections (CMM), gear quality inspections (runout, profile, lead), bearing raceway inspections, hardness testing, and potentially functional testing of assembled units, is essential but costly.

Sealing & Protection (IP65): High-performance sealing systems using specialized materials and designs to reliably achieve IP65 protection add complexity and cost compared to basic or lower-rated seals.

Bearing Quality & Configuration: The type, size, quality grade, and preload of the rolling elements (balls, rollers) within the integral slewing bearing significantly influence cost. High-capacity bearings meeting dynamic and static load ratings demand premium components.

Gear Design & Finishing: Helical gears generally cost more to manufacture than spur gears due to more complex machining. The level of gear finishing (e.g., grinding vs. shaving) impacts noise, efficiency, and cost. Precision grinding is essential for high-performance drives but expensive.

Scale & Production Volume: While the SP-H 0955 is a specific model, overall production volumes and economies of scale within the manufacturer's facility can influence unit cost. Customizations or low-volume batches typically carry a premium.

Supplier Reputation & Value-Add: Established manufacturers with proven reliability, extensive technical support, comprehensive warranties, and global service networks often command a premium that reflects reduced risk and long-term value for the customer.

Market Demand & Competition: Broader market conditions and the competitive landscape within the heavy-duty slewing drive sector can influence pricing strategies, though the technical nature and high barriers to entry tend to moderate purely price-driven competition at this performance level.

Leading Supplier of Heavy Duty Gear Slewing Drive SP-H 0955

LYRADRIVE has established itself as a prominent global supplier and manufacturer specializing in high-performance slewing drives and slewing bearings, including the robust SP-H 0955 model. Leveraging advanced manufacturing capabilities and stringent quality control systems, LYRADRIVE delivers components renowned for their reliability, precision engineering, and ability to withstand the most demanding operational conditions across diverse industries like heavy construction, material handling, renewable energy, and industrial automation. Their commitment to integrated solutions, technical expertise, and providing units designed for interchangeability (notably with the IMO SP-H 0955 specification) positions them as a trusted partner for engineers and OEMs seeking dependable rotary motion solutions backed by strong customer support and a focus on minimizing total cost of ownership through extended service life and reduced maintenance. Choosing LYRADRIVE means sourcing a critical drive component engineered for peak performance and long-term durability