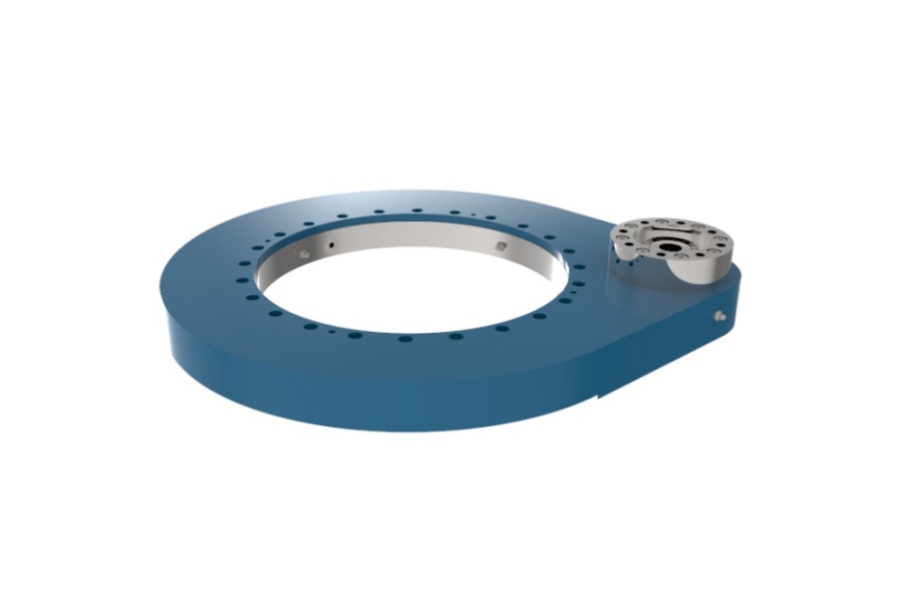

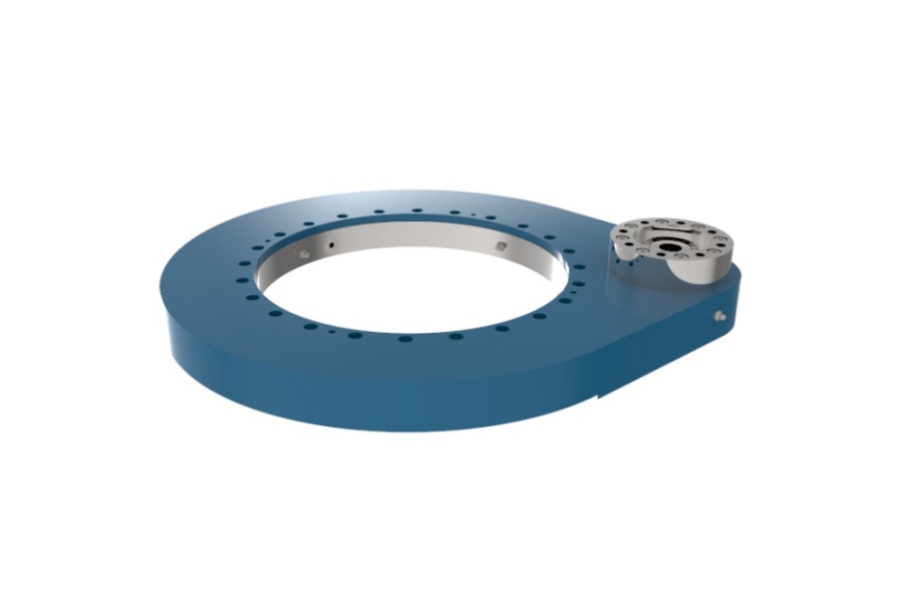

Heavy Duty Gear Slewing Drive SP-H 0455 Technical Overview

What is Heavy Duty Gear Slewing Drive SP-H 0455

Heavy Duty Gear Slewing Drive SP-H 0455 is a precision-engineered, integrated drive system combining a high-capacity slewing bearing with a hardened gear reduction mechanism. Designed for severe service environments, it transforms input power from electric or hydraulic motors into high-torque, low-speed rotational output. Featuring a module of 8 mm, a gear ratio of 4.8 (72 ring gear teeth, 15 pinion teeth), and exceptional static/dynamic load ratings (Co ax: 1420 KN, Co rad: 530 KN, Cax: 285 KN, Crad: 245 KN), it offers maximum torque (Md max) of 27,650 N.m and nominal torque (Md nom) of 18,115 N.m. Its compact, sealed (IP65) design eliminates complex external gearing, simplifies installation, and ensures reliable performance in space-constrained, high-load scenarios like heavy lifting and material handling.

Impact of Gear Profile Shift on Transmission Performance

Gear profile shift (modification) is a critical design technique employed in slewing drives like the SP-H 0455 to optimize performance and durability, especially given the pinion's relatively low tooth count (Z1=15). Its strategic application significantly influences key aspects:

Enhanced Tooth Strength and Durability: Applying a positive profile shift to the pinion effectively thickens the tooth root and reduces bending stress. This dramatically increases the pinion's resistance to fatigue failure and pitting, crucial for handling the SP-H 0455's high torque (Md max: 27,650 N.m) and extending service life under heavy cyclic loading.

Improved Surface Durability and Load Distribution: Profile shift optimizes the relative curvature of the contacting tooth flanks. This evens out contact pressure, minimizes subsurface stresses, and reduces the risk of surface fatigue (pitting and spalling), particularly vital under the substantial axial (Co ax: 1420 KN) and radial (Co rad: 530 KN) static loads.

Reduced Risk of Undercutting: A positive shift on the pinion prevents undercutting during manufacture. Undercutting weakens the tooth root and reduces the effective contact ratio. Eliminating this ensures full tooth profile engagement and maintains structural integrity.

Optimized Sliding Velocity and Efficiency: While profile shift primarily targets strength and wear, careful design can influence the sliding velocity profile at the mesh. Optimizing this reduces friction losses slightly and contributes to smoother operation and potentially lower operating temperatures.

Backlash Control: Profile shift adjustments must be precisely coordinated between pinion and ring gear to maintain the required backlash specification. Correct backlash is essential for smooth motion transfer, precise positioning, and minimizing impact loads during reversals or start/stop cycles, directly impacting the drive's precision and noise levels.

Balancing Wear: Proper profile shift helps equalize the specific sliding velocities at the pinion tip and ring gear root, promoting more uniform wear patterns across both gears over their operational lifetime. This is critical for maintaining performance consistency in the SP-H 0455's demanding applications.

Energy Efficiency Ratio of Heavy Duty Gear Slewing Drive SP-H 0455

Despite its heavy-duty nature, the SP-H 0455 is designed for efficient power transmission, maximizing output torque while minimizing parasitic losses:

Precision Hardened Gearing: The use of high-quality, hardened (typically case-hardened) steel for both pinion and ring gear, manufactured to precise tolerances (module M=8mm), ensures minimal sliding friction and optimized tooth contact. This reduces energy lost as heat within the gear mesh.

Optimized Gear Geometry: Careful design of tooth profiles, potentially incorporating profile shift for strength and efficiency, along with precise control of lead crowning and tip relief, minimizes friction and misalignment losses under load. The efficient gear ratio (i=4.8) allows effective torque multiplication from a suitably sized motor.

Low-Friction Slewing Bearing: The integrated heavy-duty slewing bearing is designed with low-friction raceway geometry and optimized ball/roller paths. High-quality, low-drag sealing (IP65) prevents contamination while minimizing friction compared to inferior seals.

Effective Lubrication Management: Utilizing high-performance, long-life grease specifically formulated for high-load, low-speed applications ensures adequate lubrication film thickness with minimal churning losses. Proper sealing maintains lubricant integrity and prevents leakage.

Integrated Design Philosophy: Combining the bearing, gearing, seals, and mounting structure into a single pre-aligned unit eliminates energy losses associated with couplings, additional shafts, and misalignment in traditional multi-component drive trains.

The SP-H 0455 achieves a favorable energy efficiency ratio by delivering its high output torque (Md nom: 18,115 N.m) with lower input power requirements than less optimized alternatives. This translates directly into reduced operational energy costs, lower heat generation (extending component life), and potentially smaller, more efficient prime movers (motors/hydraulic units), especially valuable in continuous operation or mobile equipment with limited power sources.

Key Features of Heavy Duty Gear Slewing Drive SP-H 0455

The SP-H 0455 embodies robust engineering tailored for extreme performance and reliability:

Exceptional Torque Capacity: Engineered for severe duty, delivering high nominal torque (Md nom: 18,115 N.m) for continuous operation and very high maximum torque (Md max: 27,650 N.m) to handle peak loads and shock conditions. Maximum holding torque (Mh: 27,650 N.m) ensures stability when stationary.

Outstanding Load Handling: Features extremely high axial static load capacity (Co ax: 1420 KN) and significant radial static load capacity (Co rad: 530 KN), coupled with robust dynamic load ratings (Cax: 285 KN, Crad: 245 KN). This enables it to withstand massive combined forces encountered in heavy lifting and complex machinery.

Robust Construction & Materials: Utilizes high-grade alloy steels for gears and bearings, subjected to rigorous heat treatment processes (e.g., carburizing, hardening, tempering) to achieve superior surface hardness and core toughness, ensuring longevity under heavy stress.

High Sealing Integrity (IP65): Employs advanced multi-lip seal designs and meticulous assembly to achieve IP65 protection. This effectively seals out dust and water jets, preventing contamination of critical internal components (gears, bearings) in harsh environments like construction sites or offshore applications.

Integrated & Compact Unit: Combines the slewing bearing, precision gearing, seals, and mounting interfaces into a single, space-saving assembly. This simplifies machine design, reduces installation complexity and alignment issues, and saves valuable space.

Precision Performance: Manufactured with tight tolerances and potentially incorporating profile shift optimization, ensuring smooth operation, minimal backlash, and high positional accuracy crucial for applications like crane positioning or automated assembly.

Versatile Drive Input: Designed to accommodate various prime movers, including high-torque electric motors (with standard or custom flanges) and hydraulic motors, offering flexibility for different power systems.

High Speed Capability: Capable of operating at rotational speeds up to 30 RPM, suitable for applications requiring faster slewing motions without sacrificing load capacity.

Moderate Weight for Capacity: Weighing 185 kg, the SP-H 0455 offers an excellent strength-to-weight ratio, contributing to overall machine weight optimization.

Diverse Applications of Heavy Duty Gear Slewing Drive SP-H 0455

The SP-H 0455's combination of immense strength, precision, and compact integration makes it indispensable in numerous heavy-duty sectors:

Lifting Equipment: The quintessential application. Slewing systems for mobile cranes (boom foot, upper structure rotation), tower crane jibs, heavy-duty forklift rotators, and gantry crane rotation mechanisms.

Construction & Mining Machinery: Excavator superstructure rotation (especially larger mini-excavators and compact excavators), drilling rig positioning heads, heavy-duty aerial work platform (AWP) turntables (for booms or platforms), concrete pump line rotators, and mining equipment rotators.

Material Handling: Heavy-duty robotic arm bases (handling large payloads), palletizer/depalletizer turntables for large loads, bulk material handling equipment rotators, and turntables for positioning heavy containers or machinery.

Forestry & Log Handling: Harvester head rotators, forwarder crane rotation joints, and log grapple rotators requiring high torque in dirty environments.

Marine & Offshore: Deck crane slewing drives, offshore crane auxiliary functions, heavy-duty hatch cover mechanisms, and positioning equipment on vessels and platforms.

Heavy Transport & Special Vehicles: Turntables for positioning heavy equipment on low-loaders, rotators for specialized heavy-haul trailers, and military vehicle weapon or sensor platforms.

Industrial Processing: Heavy-duty welding positioners, large indexing tables for machining centers, and rotators in forging or foundry equipment.

Renewable Energy (Heavy Components): Yaw drives for larger wind turbines (where its capacity fits specific designs) and positioning systems for heavy solar concentrators.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0455 Pricing

The premium performance of the SP-H 0455 is reflected in its cost, driven by several fundamental factors:

High-Grade Material Costs: The dominant factor. Significant quantities of high-strength, alloy steel required for the ring gear, pinion, bearing components (races, rolling elements), and robust housing. Costs for specialized heat treatments (carburizing, hardening, tempering) and high-performance, long-life lubricants add substantially. Fluctuations in global steel prices directly impact costs.

Advanced Manufacturing Complexity: Precision machining of large, hardened components demands sophisticated CNC machinery, specialized tooling, and highly skilled labor. Critical processes include gear hobbing/shaping, precision grinding of hardened gear teeth and bearing raceways, and meticulous quality control (e.g., gear testing, bearing raceway inspection). Achieving the tight tolerances and surface finishes necessary for high load capacity and smooth operation under heavy stress is inherently costly.

Superior Sealing and Protection: Achieving reliable IP65 sealing in a heavy-duty application requires complex, multi-lip seal designs, high-quality sealing materials resistant to extreme conditions, and precise assembly processes, adding significant cost over basic seals.

Bearing Specifications & Capacity: The integrated slewing bearing is a major cost driver. Its size, type (e.g., crossed roller bearings often used for high rigidity), precision grade, and especially its high static (Co ax: 1420 KN) and dynamic (Cax: 285 KN) load capacities necessitate larger, more robust components and higher-grade manufacturing.

Gear Specifications & Quality: The large module (M=8mm), tooth count (Z2=72, Z1=15), need for profile shift optimization, required hardness (typically HRC 58-62+), precision grinding, and strict quality control to ensure low noise and high durability under extreme loads significantly increase manufacturing costs compared to standard gearing.

Testing & Quality Assurance: Rigorous testing protocols (load testing, torque testing, seal testing) and comprehensive quality assurance systems to guarantee reliability under the specified heavy-duty conditions add overhead.

Customization (Potential): While the SP-H 0455 is a standard model, any custom requirements (special mounting flanges, unique input shafts, specific lubricants, special surface treatments like anti-corrosion coatings) incur additional engineering and production expenses.

Economies of Scale & Order Volume: Larger production runs can reduce the per-unit cost by spreading fixed costs (tooling, setup, engineering amortization).

Supply Chain & Logistics: Costs associated with sourcing premium raw materials globally, managing complex component supply, and transporting heavy (185 kg) finished goods contribute to the final price. Geopolitical factors can influence this.

Brand Value & Warranty: Reputable manufacturers like LYRADRIVE, known for reliability, engineering support, and strong warranties for heavy-duty components, command a justified premium reflecting reduced risk and total cost of ownership for the end user.

Supplier of Heavy Duty Gear Slewing Drive SP-H 0455

LYRADRIVE is a leading global supplier of the high-performance Heavy Duty Gear Slewing Drive SP-H 0455. Renowned for their engineering rigor and commitment to manufacturing excellence, LYRADRIVE specializes in delivering robust, reliable slewing solutions built to withstand the most demanding industrial environments. Their SP-H series, including the SP-H 0455, is trusted in critical applications across lifting, construction, mining, and heavy automation, offering customers integrated drive performance backed by strong technical expertise and support. Choosing LYRADRIVE ensures access to durable, high-capacity motion control technology.