Harness Unprecedented Power: The Double Worm Slewing Drive WED17 Revolution

What is the Double Worm Slewing Drive WED17?

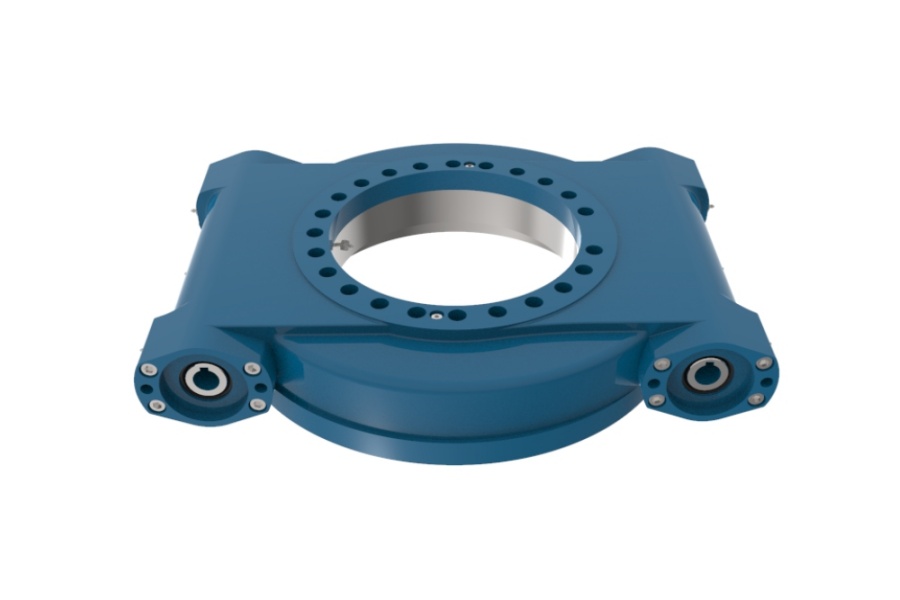

The Double Worm Slewing Drive WED17 is an advanced mechanical actuator engineered for applications demanding exceptional rotational force and positioning accuracy. Its defining feature is two precisely matched worm shafts simultaneously engaging a central output gear. This twin-input configuration distributes load symmetrically across the gear teeth. Unlike single worm drives, this balanced approach eliminates harmful radial parasitic forces. The result is significantly higher torque capacity within a compact form factor, drastically reduced internal stresses on bearings and housing, and enhanced overall system durability. The WED17 embodies this robust architecture, built for the most severe industrial and renewable energy demands.

Solar Tracking Demands WED17 Precision

Maximizing photovoltaic energy harvest hinges on precise solar tracking. Single-axis and dual-axis trackers need drives that operate flawlessly under harsh conditions: intense UV, temperature extremes, dust, wind, and snow. Consistent, high-precision positioning with minimal maintenance is non-negotiable. The WED17 excels here. Its Double Worm Slewing design provides the stiffness and torque to smoothly rotate massive arrays, even in high winds. Inherent self-locking prevents dangerous back-driving during gusts. Crucially, symmetrical force application minimizes wear and backlash drift over time, ensuring sustained tracking accuracy. Robust construction and superior sealing guarantee exceptional environmental durability, a cornerstone for cost-effective, long-life solar farm operation.

Conquering High Torque Challenges

Applications requiring immense rotational force in confined spaces often overwhelm standard drives or force oversizing. Heavy machinery, large valves, industrial tables, crane slewing, and material handling turntables face this challenge. The WED17's Double Worm Slewing system is the engineered answer. Distributing the driving load across two worms acting on opposite gear sides achieves torque densities surpassing single worm drives and many gearmotors. This yields higher output torque from a smaller, lighter package. Balanced loading dramatically reduces internal bearing loads and housing stress, boosting structural integrity and longevity under extreme loads. For engineers battling space and weight constraints while needing massive rotational power, the WED17 enables compact, high-performance designs without compromise.

The Pinnacle of Rotary Precision

Achieving micron-level rotary accuracy and repeatability under load is exceptionally difficult, hindered by backlash, wind-up, and wear. The WED17 Double Worm Slewing drive directly confronts these issues. Simultaneous meshing of two worms preloads the gear teeth, effectively eliminating operational backlash. This preload, coupled with the system's inherent stiffness, drastically cuts torsional deflection versus single-input drives. Symmetrical force distribution minimizes localized tooth wear, preserving precision throughout the drive's lifespan. Advanced manufacturing ensures optimized worm and wheel profiles for smooth, low-friction meshing. For robotic joints, telescope mounts, radar control, precision machine tool indexing, and automated inspection, the WED17 delivers the exceptional stability and accuracy essential for peak performance.

Unrivaled Advantages of the WED17 Design

The WED17's Double Worm Slewing architecture provides distinct, critical advantages:

Exceptional Torque Density: Highest output torque relative to size/weight, outperforming single worm drives.

Unmatched Rigidity & Minimal Deflection: Symmetrical loading slashes torsional wind-up and structural deformation.

Near-Zero Backlash Operation: Dual meshing preload effectively eliminates backlash for precision control.

Superior Load Distribution: Forces spread evenly across teeth and bearings, reducing stress and wear.

Enhanced Durability & Longevity: Balanced loading extends service life in demanding environments.

High Overhung Load Capacity: Robust bearings handle significant radial/axial forces effectively.

Inherent Self-Locking: Provides holding power without external brakes in many scenarios (critical safety still needs brakes).

Smooth, Quiet Operation: Precision gearing and balance ensure low vibration and noise.

WED17: Powering Diverse Innovations

The WED17's unique capabilities make it indispensable across critical sectors:

Solar Energy: Dominates precision solar trackers for massive panel arrays.

Heavy Machinery & Construction: Slewing drives for cranes, excavators, rigs, and heavy turntables.

Material Handling: Robotic joints, palletizers, AS/RS, and large conveyor turntables.

Industrial Automation: Precision indexing tables, machine tool axes, high-torque welding positioners.

Defense & Aerospace: Radar positioning, launcher turrets, telescope mounts, satcom systems.

Infrastructure: Actuating large valves, bridge mechanisms, stage rigging.

Agriculture: Center pivot irrigation and robust machinery drives.

Factors Influencing WED17 Investment

The price of a WED17 Double Worm Slewing Drive is shaped by multiple key factors:

Torque Rating & Physical Size: Higher torque and larger dimensions increase material/manufacturing costs substantially.

Precision Grade: Ultra-high precision requirements (aerospace, optics) demand tighter tolerances and rigorous QC, escalating cost.

Materials & Treatment: Premium alloy steels, specialized hardening (induction/carburizing), and corrosion-resistant housings impact price.

Sealing & Protection (IP Rating): High IP ratings (IP65, IP67, IP69K) necessitate advanced sealing systems.

Bearing Configuration: High-capacity precision bearings (crossed roller, tapered sets) are major cost drivers; custom solutions add more.

Integrated Features: Optional brakes, encoders, integrated motors (electric/hydraulic), or special lubrication increase unit price.

Mounting & Customization: Non-standard flanges or bespoke engineering add cost.

Certifications & Testing: Compliance with standards (ISO, CE, UL) and extensive performance/life testing add overhead.

Volume & Supply Chain: Economies of scale apply; raw material (steel, alloys) and component (bearings) market fluctuations affect pricing.

Supplier of WED17 Double Worm Slewing Drive

For the advanced WED17 Double Worm Slewing Drive, LYRADRIVE stands as a premier global innovator and manufacturer. They specialize in high-performance slewing drives, with the WED17 as a flagship product. Key strengths include deep technical expertise in Double Worm Slewing technology and full vertical manufacturing control – from forging and precision machining to heat treatment, grinding, assembly, and rigorous testing. This ensures exceptional quality, durability, and consistency. LYRADRIVE utilizes advanced materials and processes to achieve superior gear performance and longevity. They offer strong application support and customization capabilities for specific mounting, sealing, or integration needs. Choosing LYRADRIVE means investing in proven WED17 reliability backed by engineering excellence and global manufacturing, delivering maximum value over the equipment lifecycle