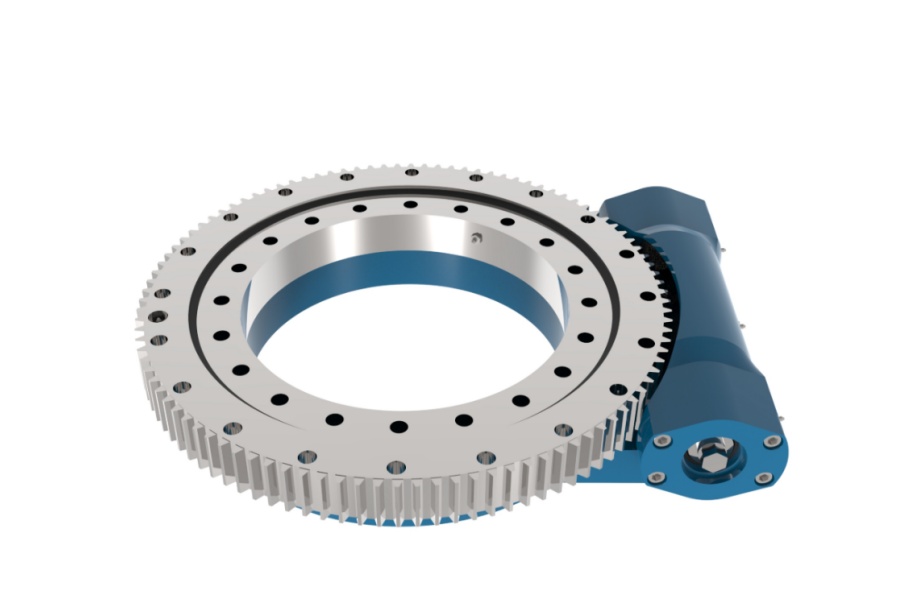

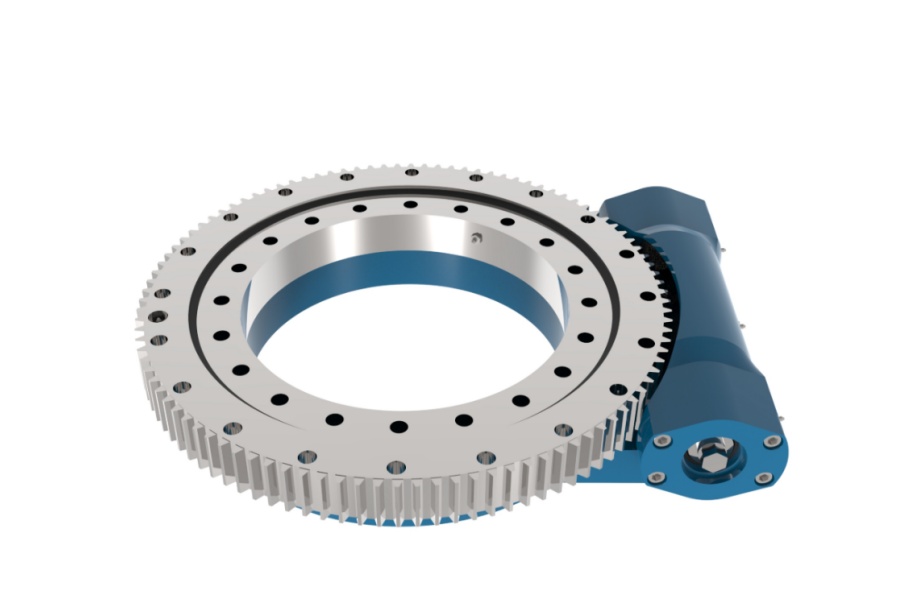

Industrial Innovation Unleashed: The Open Housing Slewing Drive S19 - Power, Resilience, and Uncompromising Performance

What is the Open Housing Slewing Drive S19?

The Open Housing Slewing Drive S19 is a precision-engineered rotational actuator designed for transmitting high torque while supporting substantial axial, radial, and moment loads. Its defining characteristic is its open-frame or "open housing" construction. Unlike conventional slewing drives encased in a sealed, often cast housing, the S19 features a robust structural frame that exposes key internal components like the large-diameter slewing bearing and, in many configurations, the gearing. This design philosophy prioritizes maximum heat dissipation, exceptional accessibility for inspection and maintenance, and inherent modularity. The S19 typically integrates a high-precision worm gear set (worm and wheel) or planetary gearbox driving the large slewing bearing, providing a compact yet immensely powerful solution for applications requiring controlled, high-torque rotation. The open structure allows for direct visual confirmation of component engagement and wear, a significant advantage in critical operations.

Unstoppable Performance: Mastering High-Temperature Rotation

Operating reliably under intense heat is a core strength of the Open Housing Slewing Drive S19. Traditional enclosed drives trap heat generated by friction, gear meshing, and external sources, accelerating lubricant degradation and component wear, leading to premature failure. The S19's open architecture acts as a massive heat sink. Ambient air circulates freely around the bearing raceways, gear teeth, and housing structure, dramatically improving convective cooling. This allows the S19 to operate consistently and efficiently in environments where temperatures would cripple standard units – think furnace tilting mechanisms, high-temperature material handling near kilns or reactors, heavy machinery in foundries, or solar trackers in desert climates. Furthermore, this design permits the use of specialized high-temperature greases or even circulating oil systems where extreme conditions demand it. The inherent thermal management significantly extends component life, reduces downtime for cooling, and ensures dependable performance when heat is an unavoidable factor.

Revolutionizing Uptime: The Power of Slewing Drive Field Repair

The Open Housing Slewing Drive S19 fundamentally changes the maintenance paradigm through its unparalleled field-serviceability. When a traditional sealed slewing drive fails or requires maintenance, the typical solution involves a complex, costly, and time-consuming process: complete unit removal, shipment to a specialized facility, disassembly (often destructive), component replacement, reassembly, testing, and reinstallation – leading to extended, expensive downtime. The S19 eliminates this logistical nightmare. Its open design allows technicians direct access to critical wear components – the worm gear, wheel gear, slewing bearing races, and seals – in situ, right on the machine. Worn gears or bearings can be inspected, assessed, and replaced individually without extracting the entire drive unit. Modular components simplify the process further. This capability drastically reduces Mean Time To Repair (MTTR), minimizes costly production interruptions, lowers overall maintenance expenses by avoiding full unit replacements for minor issues, and empowers operators with greater control over their equipment lifecycle. Field repair transforms maintenance from a disruptive event into a manageable, efficient process.

Engineered Excellence: Defining Features of the S19

The Open Housing Slewing Drive S19 distinguishes itself through a suite of powerful features engineered for demanding performance:

Superior Thermal Management: The open-frame design maximizes natural convection cooling, enabling sustained operation in high-heat environments far exceeding the capabilities of enclosed drives.

Unmatched Serviceability: Direct, on-site access to all critical wear components (gears, bearings, seals) enables rapid inspection, maintenance, and component replacement without removing the entire drive, revolutionizing uptime.

Exceptional Load Capacity: Engineered with robust materials and precision manufacturing, the S19 handles very high axial, radial, and moment loads simultaneously, providing stability and power for heavy-duty applications.

Modular Design Philosophy: Key components are designed for individual replacement, simplifying repairs, reducing spare parts inventory complexity, and extending the overall system lifespan.

High Efficiency & Precision: Optimized gear geometry and premium bearing selection ensure efficient power transmission, minimal backlash, and precise rotational control.

Enhanced Lubrication Access: Easy access points facilitate regular greasing or oil changes, crucial for maintaining performance and longevity, especially under harsh conditions.

Robust Construction: Built from high-strength alloys and utilizing hardened gear teeth and bearing races, the S19 is designed for durability and resistance to wear in abrasive or demanding environments.

Customization Potential: The inherent design flexibility of the open frame allows for easier adaptation of mounting configurations, sealing solutions, or integration of specific gear ratios compared to fixed-cast designs.

Powering Diverse Industries: S19 Applications

The unique combination of strength, heat tolerance, and serviceability makes the Open Housing Slewing Drive S19 ideal for numerous challenging sectors:

Heavy Industrial Machinery: Furnace tilting and charging equipment, ladle turrets, manipulators, heavy-duty material handling arms, mixer/reactor drives in chemical and processing plants – environments where heat and heavy loads are constant.

Renewable Energy: Solar tracker azimuth and elevation drives, particularly in high-insolation desert regions where ambient temperatures soar and reliability is paramount for energy yield. Also suitable for wind turbine yaw drive backup systems or component positioning.

Construction & Mining: Crane jib rotation, drilling rig positioning, heavy excavator attachment rotation, conveyor slew drives – applications demanding robustness under shock loads and in dusty conditions.

Material Handling: Robotic welding positioners, large rotary tables for machining or assembly, automated storage and retrieval system (AS/RS) rotators, vessel rotators – requiring precision and reliability.

Specialty Vehicles: Firefighting turrets, specialized utility vehicle booms, military equipment mounts – where field maintenance capability is critical.

Marine & Offshore: Deck crane rotation, winch positioning, handling equipment on vessels and platforms – handling corrosive environments and heavy loads.

Understanding Investment: Factors Influencing S19 Pricing

The cost of an Open Housing Slewing Drive S19 is influenced by several key variables:

Size & Torque Capacity: Larger drives designed for higher torque output inherently require more material, larger bearings, and more robust gearing, increasing cost significantly.

Gear Ratio: Complex or very high-ratio gear sets require more intricate manufacturing and potentially more components.

Load Ratings: Drives specified for extreme axial/radial/moment loads necessitate premium bearing selections, reinforced structural components, and rigorous engineering validation.

Material Specifications: Use of specialized alloys for enhanced strength, corrosion resistance (e.g., stainless steel components), or high-temperature performance adds cost. The grade and hardening processes for gears and bearings are major factors.

Sealing & Environmental Protection: While open, specific IP ratings or protection against harsh contaminants (dust, water, chemicals) require advanced sealing solutions which add complexity and cost.

Customization: Modifications to standard mounting patterns, special shaft configurations, unique lubrication systems, or integration of sensors drive up engineering and manufacturing costs.

Bearing Type & Quality: The specification of the core slewing bearing (crossed roller, three-row roller, ball bearing) and its quality tier (precision grade, material) is a primary cost driver.

Worm/Wheel Specifications: Material (e.g., hardened steel, bronze), heat treatment, precision grinding level, and surface finish significantly impact cost and performance.

Brand Reputation & Engineering Support: Established manufacturers with proven reliability, comprehensive engineering support, and stringent quality control often command a premium, reflecting the value of reduced risk and downtime.

Order Volume & Supply Chain: Economies of scale apply, and global raw material costs and logistics impact final pricing.

Supplier of Open Housing Slewing Drive S19

When investing in the advanced technology of the Open Housing Slewing Drive S19, partnering with the right supplier is crucial for performance, reliability, and long-term support. LYRADRIVE stands as a premier designer and manufacturer of high-performance slewing drives, including the innovative S19 series.

Choosing LYRADRIVE for your Open Housing Slewing Drive S19 means selecting more than just a component; it's partnering with an expert committed to delivering the strength, resilience, and operational efficiency required for the most challenging industrial environments. The S19, backed by LYRADRIVE's engineering excellence and support, represents a smart investment in maximizing productivity and minimizing lifecycle costs.