Flanged Four Contact Ball Slewing Bearing Engineering Excellence for Demanding Rotation

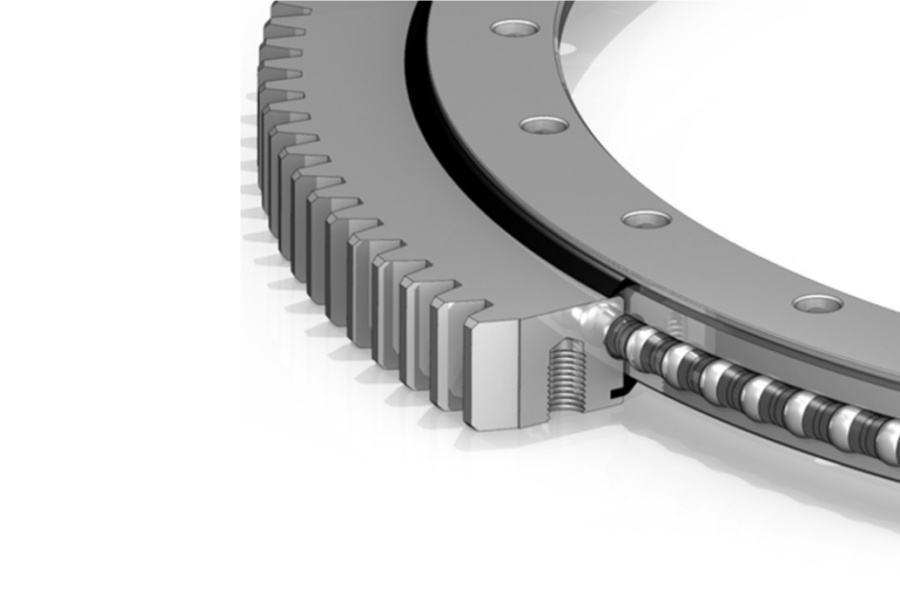

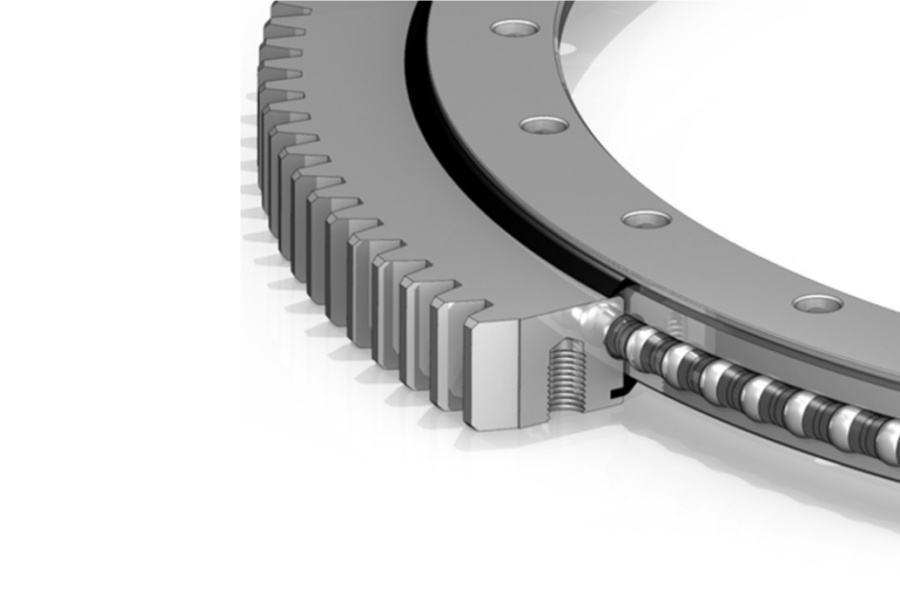

What is Flanged Four Contact Ball Slewing Bearing

Flanged Four Contact Ball Slewing Bearing is a specialized type of four-point contact ball slewing bearing distinguished by its unique L-shaped flange integrated onto either the inner ring or outer ring. This fundamental design modification significantly enhances mounting flexibility, structural rigidity, and weight reduction compared to standard non-flanged designs. At its core, it consists of an outer ring, an inner ring, hardened steel balls acting as the rolling elements, and either spacers or a cage to maintain precise ball separation. The defining characteristic is the use of a gothic arch (or "peach-shaped") raceway geometry. This profile allows each ball to make contact with the raceways at four distinct points under load, enabling the bearing to handle combined loads very effectively. Critical manufacturing steps include medium-frequency induction hardening of the raceways to achieve exceptional surface hardness (typically HRC 55-60) and a controlled hardened depth (2.5-5 mm), ensuring long-term durability and resistance to brinelling. Precise calculation of the raceway curvature radius is paramount to guarantee smooth rolling motion with minimal friction and energy loss. Variations include Double Flange (flanges on both rings), External Flange with Internal Gear, External Gear with Internal Flange, and Double External Flange configurations, catering to diverse mounting and drive requirements.

Analyzing Anti-Corrosion Design in Slewing Drives

The longevity and reliable performance of Flanged Four Contact Ball Slewing Bearings, especially in harsh operating environments prevalent in industries like food processing, chemical handling, marine, and agriculture, heavily depend on effective corrosion protection. This involves a multi-faceted approach starting with material selection. While standard bearings often use 50Mn or 42CrMo alloy steels, applications demanding superior corrosion resistance utilize stainless steel grades (like AISI 440C or specialized martensitic stainless steels) for rings and balls, albeit often at a higher cost and potentially lower load capacity compared to hardened carbon steels. Surface treatments are crucial for carbon steel bearings. Common methods include:

Zinc or Zinc-Nickel Plating: Provides a sacrificial barrier layer and basic protection.

Phosphating (Parkerizing): Creates a micro-crystalline phosphate layer that enhances paint adhesion and offers moderate corrosion resistance.

Dacromet/Geomet Coatings: Offer superior salt-spray resistance compared to standard zinc plating through a zinc-aluminum flake coating in a chromate binder.

Specialized Anti-Corrosion Paints: Applied to non-raceway external surfaces.

Robust sealing is the first line of defense against ingress of water, chemicals, and abrasive contaminants. Multi-lip seals made from materials resistant to specific chemicals (NBR, FKM/Viton, PTFE) are standard. For extreme environments, labyrinth seals or specialized exclusion seals offer enhanced protection. Finally, internal lubrication plays a vital role. Using high-quality, water-resistant greases, sometimes incorporating corrosion inhibitors, and ensuring proper re-lubrication intervals, protects internal surfaces and displaces any minor moisture ingress. The optimal anti-corrosion strategy is determined by the specific environmental challenges the bearing will face throughout its operational life.

Energy Efficiency Ratio of Flanged Four Contact Ball Slewing Bearing

The Flanged Four Contact Ball Slewing Bearing exhibits a favorable energy efficiency ratio primarily due to its inherent low-friction design. The four-point contact geometry, when precisely manufactured with optimal raceway curvatures and surface finishes (achieved through grinding post-hardening), minimizes rolling resistance. This precision ensures that the balls roll smoothly with minimal sliding friction within the raceways. The use of low-friction cages or spacers further reduces parasitic drag. Compared to roller-type slewing bearings (like crossed roller or three-row roller designs), ball bearings generally have lower starting and running torque, translating directly to lower energy consumption in the driving system (motors, hydraulic units). The flanged design contributes indirectly to efficiency by enabling a more compact and rigid overall structure. This rigidity minimizes system deflections under load, preventing misalignment that could increase friction. Furthermore, the potential for weight reduction using flanged designs, especially with forged alloy steel, means less mass needs to be accelerated and decelerated, reducing the inertial energy demands of the application. While factors like seal drag and lubrication viscosity also influence overall energy consumption, the fundamental rolling element design of the Flanged Four Contact Ball Slewing Bearing positions it as an energy-efficient choice for rotational motion.

Key Features of Flanged Four Contact Ball Slewing Bearing

The Flanged Four Contact Ball Slewing Bearing offers a compelling set of features that make it suitable for diverse demanding applications:

High Load Capacity: The four-point contact ball design enables efficient handling of substantial combined loads (axial, radial, and tilting moments) within a relatively compact envelope.

Compact & Lightweight Design: The integration of the L-shaped flange directly onto the ring eliminates the need for separate, bulky mounting flanges, significantly reducing overall system weight and size. This is particularly advantageous in applications where weight is critical.

Structural Rigidity: The flange provides a large, stable mounting surface, enhancing the connection stiffness between the bearing and the supporting structures, leading to improved system accuracy and reduced deflection under load.

Mounting Flexibility & Simplicity: Flanges simplify the installation process, often requiring only bolts through the flange into the adjacent structure, reducing assembly time and complexity compared to designs requiring clamps or complex housings.

Smooth Rotation & Low Friction: Precision-ground raceways and optimized ball contact ensure smooth, low-torque rotation, contributing to energy efficiency and precise positioning.

High Rotational Speed Capability: Compared to many roller slewing bearings, the ball design generally allows for higher operational speeds.

Material Versatility: Manufactured from high-quality materials including 50Mn, 42CrMo alloy steel (standard), stainless steels (corrosion-resistant), and notably forged alloy steel. Forged alloy steel offers superior metallurgical properties (grain flow), enhanced stability, and significantly extended service life under high loads and demanding conditions.

Configuration Options: Available in various configurations (Double Flange, External Flange Internal Gear, External Gear Internal Flange, Double External Flange) to suit specific mounting and drive needs (e.g., pinion drive requirements).

Durability: Raceway surface hardening (HRC 55-60) and deep case hardening (2.5-5mm) provide excellent resistance to wear and fatigue.

Applications of Flanged Four Contact Ball Slewing Bearing

The unique combination of compactness, high load capacity, rigidity, and smooth operation makes the Flanged Four Contact Ball Slewing Bearing indispensable across numerous industries:

Material Handling & Logistics: Rotary conveyors, indexing tables, palletizers/depalletizers, automated guided vehicles (AGVs), baggage handling systems.

Packaging & Food/Beverage Machinery: Filling machines, capping machines, labeling machines, rotary platforms for processing, washing systems. Corrosion-resistant variants are essential here.

Agricultural Machinery: Combine harvesters (reel drives, grain tank augers), sprayer booms, fertilizer spreaders, bale wrappers.

Construction Equipment: Compact cranes (slewing jibs), concrete pump line rotation units, drilling equipment attachments.

Environmental & Recycling: Trommel screens, windrow turners, shredder feed hoppers, sorting equipment.

Renewable Energy: Solar tracker systems (requiring precision rotation and durability), smaller wind turbine yaw/pitch adjustments.

Medical & Laboratory Equipment: Robotic arms, rotary stages for imaging or sample handling (requiring smoothness and precision).

Robotics: Joints and rotational axes in industrial robots requiring compactness and high rigidity.

Transport & Turntables: Particularly the Double External Flange variant is widely used in trailer turntables for heavy transport and recovery vehicles, providing robust rotation under extreme loads. Light-duty passenger vehicle turntables also benefit.

Machine Tools: Rotary tables for machining centers (4th/5th axis), indexing fixtures.

Factors Influencing Flanged Four Contact Ball Slewing Bearing Price

The cost of a Flanged Four Contact Ball Slewing Bearing is determined by a complex interplay of several key factors:

Size & Dimensions: Larger diameter bearings inherently require more raw material and involve more complex, time-consuming machining and heat treatment processes, leading to significantly higher costs. Bore diameter, overall height, and flange dimensions all contribute.

Load Capacity & Rating: Bearings engineered to withstand higher axial, radial, and moment loads necessitate more robust designs, potentially larger balls, wider raceways, deeper hardening, and higher-grade materials, increasing the price.

Material Selection: Standard carbon alloy steels (50Mn, 42CrMo) are the baseline. Choosing stainless steel (AISI 440C, etc.) for corrosion resistance substantially increases material costs. Opting for rings made from premium forged alloy steel instead of cut or cast material commands a significant premium due to superior performance and longevity but involves higher processing costs.

Manufacturing Complexity: Standard Double Flange bearings are generally the most economical. Adding gears (internal or external) increases machining complexity and cost. Unique flange configurations or Double External Flange designs also add complexity. Precision requirements (tolerances, runout) directly impact manufacturing time and cost.

Customization & Special Features: Any deviation from standard catalog dimensions or features incurs engineering and setup costs. This includes special bolt hole patterns, non-standard sealing arrangements, unique grease types or fill quantities, custom markings, specific pre-load requirements, or special surface coatings (beyond standard anti-rust).

Anti-Corrosion Requirements: Implementing advanced corrosion protection (stainless steel, specialized coatings like Dacromet/Geomet, specific seal materials like FKM) adds considerable cost compared to standard carbon steel with basic protection.

Quality Certifications & Traceability: Bearings manufactured under stringent quality management systems (ISO 9001) with full material traceability (mill certificates, heat treatment records) and potentially requiring specific industry certifications (e.g., DNV for marine) involve additional overhead and testing, reflected in the price.

Order Quantity: Economies of scale apply significantly. Unit prices for large volume production runs are considerably lower than for one-off or small-batch orders due to amortized setup and engineering costs.

Market Dynamics & Supplier: Raw material price fluctuations (steel), energy costs, and general market demand influence pricing. Different manufacturers have varying cost structures, engineering capabilities, and brand positioning, leading to price differences for seemingly similar products.

Supplier of Flanged Four Contact Ball Slewing Bearing

LYRADRIVE stands as a recognized engineering-driven manufacturer specializing in high-performance slewing bearings and drive solutions. They offer a comprehensive range of Flanged Four Contact Ball Slewing Bearings, encompassing standard catalog designs and highly customized solutions tailored to specific application challenges. LYRADRIVE emphasizes robust engineering, utilizing advanced manufacturing techniques and stringent quality control processes, including material traceability and precision machining. Their product portfolio includes variants in standard alloy steel, corrosion-resistant stainless steel, and premium forged alloy steel options, catering to diverse performance and longevity requirements across industries like material handling, packaging, renewable energy, and heavy equipment. LYRADRIVE supports customers with technical expertise for optimal bearing selection and integration, focusing on delivering reliable rotational performance and durability. Their commitment extends beyond standard supply to providing engineered solutions for demanding rotational motion challenges