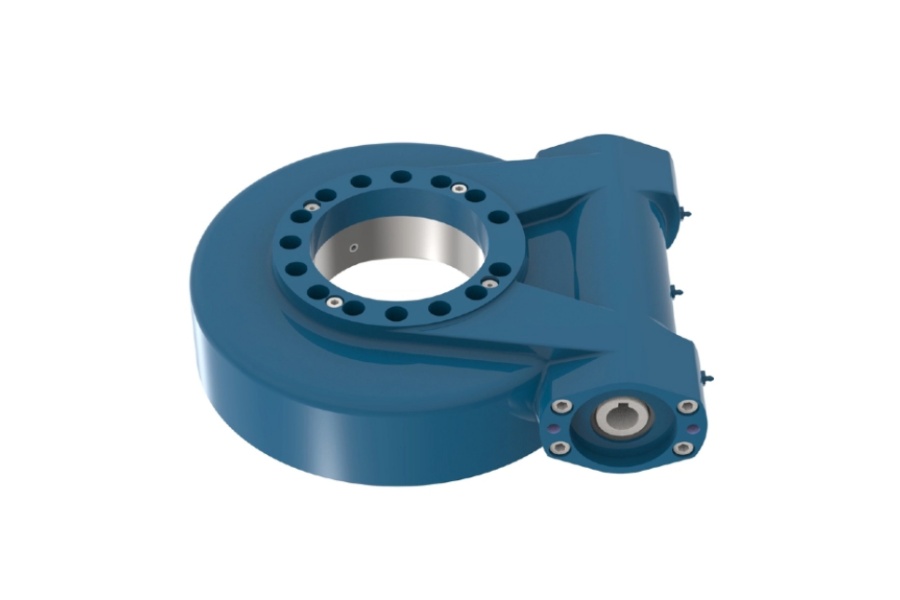

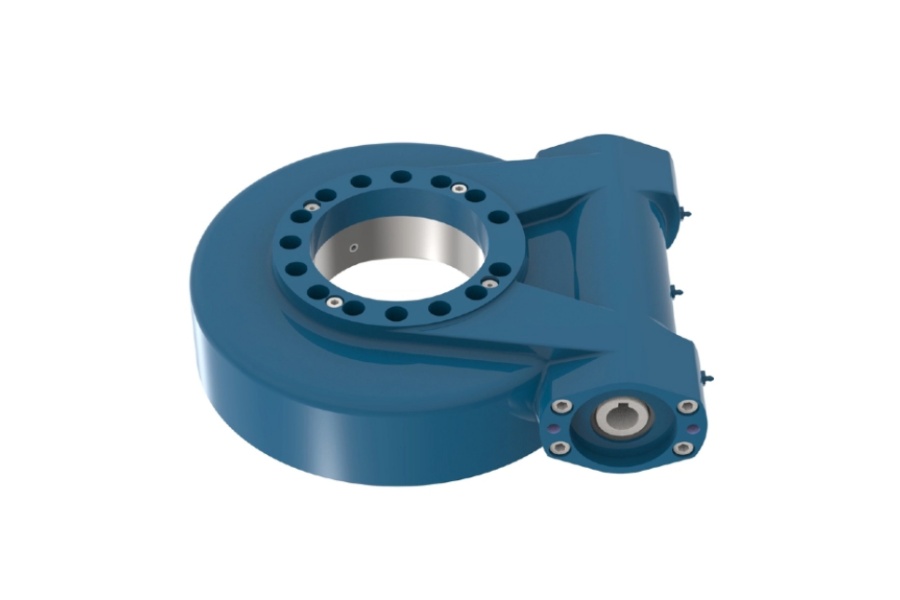

Enveloping Slewing Drive SE9 Unmatched Heavy-Duty Rotation and Precision

What is Enveloping Slewing Drive SE9

Enveloping Slewing Drive SE9 represents the pinnacle of integrated slewing drive technology for heavy-duty applications. It is a fully enclosed, unitized assembly that seamlessly combines a large-diameter slewing ring bearing with a high-torque, enveloping worm gear drive mechanism into a single, compact unit. The core of the SE9 features a hardened steel worm screw driving a precision-ground enveloping worm wheel. This unique enveloping design allows for an unprecedented 4 to 5 teeth to engage simultaneously with the worm screw. This multi-tooth contact is fundamental to the SE9's extraordinary load-bearing capacity, exceptional torque output (6.5 kN.m), immense holding torque (38.7 kN.m), smooth rotational performance, and its highly reliable self-locking characteristic. The entire mechanism is housed within a rigid, sealed enclosure, providing superior protection against environmental contaminants. This integrated design offers a pre-assembled, high-strength solution that simplifies installation and delivers unparalleled performance in the most challenging rotational applications.

Why are Slewing Ring Gears Ground?

Grinding the gear teeth on a slewing ring, particularly crucial in high-performance drives like the Enveloping Slewing Drive SE9, is an essential precision manufacturing process delivering significant benefits:

Enhanced Surface Finish: Grinding produces an extremely smooth tooth surface, drastically reducing friction and wear during operation. This is vital for efficiency and long service life, especially under heavy loads and continuous use.

Superior Dimensional Accuracy: Grinding achieves exceptionally tight tolerances on tooth profile, spacing (pitch), and lead. This precision is critical for smooth, low-vibration operation and minimal backlash.

Optimized Load Distribution: Precise tooth geometry ensures even contact patterns across the engaged teeth. This is paramount for the enveloping design of the SE9, where 4-5 teeth share the load simultaneously. Accurate grinding maximizes load distribution, preventing premature wear or failure on individual teeth and significantly boosting overall load capacity and durability.

Increased Hardness Capability: Gear teeth are typically hardened (e.g., case hardened) to withstand high contact stresses. Grinding is often the only practical method to finish teeth after hardening, maintaining the required precision and surface finish without compromising the hardened layer's integrity.

Improved Meshing Performance: Precise tooth profiles and smooth surfaces allow the worm and worm wheel to mesh more efficiently. This reduces noise, minimizes heat generation, and ensures consistent torque transmission – essential for the SE9's demanding performance specifications.

Achieving High Precision Ratings: The SE9's impressive tracking precision (≤0.17°, with options for ≤0.06° or ≤0.09°) is directly dependent on the accuracy achieved through precision grinding of the gear teeth.

Enveloping Slewing Drive SE9 Features

The SE9's advanced design translates into a formidable set of features designed for ultimate performance and reliability:

Exceptional Multi-Directional Load Capacity: Engineered to handle immense combined loads concurrently – massive axial thrust (338 kN static), significant radial forces (135 kN static), and substantial tilting moments (33.9 kN.m). This eliminates the need for complex external bearing support structures.

Unrivaled Torque Capacity: The enveloping worm gear mechanism, engaging multiple teeth simultaneously, generates immense output torque (6,500 N.m / 6.5 kN.m) and exceptional holding torque (38,700 N.m / 38.7 kN.m), far exceeding many drives in its size class.

Reliable Self-Locking: The inherent efficiency of the enveloping worm gear design ensures positive self-locking when drive power is removed. This critical safety feature prevents unintended movement due to external loads or gravity, securing loads in position.

High Precision and Smooth Operation: Precision grinding of the gear teeth, combined with multi-tooth engagement and a high gear ratio (61:1), enables very accurate positioning (≤0.17° tracking precision, tighter options available) and exceptionally smooth, low-vibration rotation.

Robust Sealing and Environmental Protection (IP65): The housing provides excellent defense against dust ingress and low-pressure water jets, making the SE9 highly suitable for harsh outdoor environments (offshore, construction, mining) and demanding industrial settings where contamination is a constant threat.

Integrated, Heavy-Duty Construction: Combining the slewing ring bearing, high-reduction gearbox, and structural mounting interfaces into one pre-assembled, sealed unit drastically simplifies system design, reduces installation complexity and time, saves space, and enhances overall structural integrity and reliability. Factory sealing ensures optimal protection.

Durability and Long Service Life: Manufactured from high-grade materials (hardened steel worm/wheel), featuring optimized load distribution through multi-tooth contact and precision grinding, and protected by effective IP65 sealing, the SE9 is built for extended operational life with minimal maintenance under continuous, severe-duty cycles.

Enveloping Slewing Drive SE9 Applications

The immense power, precision, and robustness of the Enveloping Slewing Drive SE9 make it the ideal solution for the most demanding rotational applications across heavy industries:

Heavy Construction and Mining Equipment: Found in excavator superstructures, large crane turntables, heavy-duty drilling rigs, mining shovel booms, and conveyor swing mechanisms where extreme loads and harsh environments are the norm.

Material Handling: Essential for large port cranes (STS, RTG), heavy-duty automated storage/retrieval systems (AS/RS), ship loaders/unloaders, and giant robotic manipulators requiring massive torque and precision under load.

Wind Energy: Used in yaw drives for larger wind turbines (though often requiring even higher torque capacities, the SE9 illustrates the enveloping principle for heavy drives) and heavy-duty turbine maintenance equipment.

Marine and Offshore: Applied in offshore crane pedestals, vessel-mounted A-frames, gangway rotation systems, winch drives, and dynamic positioning thruster azimuth drives demanding corrosion resistance, high loads, and reliability.

Defense and Aerospace: Employed in heavy weapon system mounts, large radar antenna pedestals, missile launcher positioning, satellite communication systems, and ground support equipment requiring utmost reliability, precision, and load capacity.

Industrial Automation: Used in very large welding positioners, foundry equipment turntables, heavy-duty indexing tables for machining centers, and massive material processing carousels.

Energy Sector: Found in large valve actuators for pipelines/power plants, heavy-duty solar tracker foundations for concentrated solar power (CSP), and equipment positioning within power generation facilities.

Specialized Heavy Machinery: Applicable in tunnel boring machine (TBM) segment erectors, piling rig rotation units, and other bespoke heavy industrial machinery requiring robust, precise rotation.

Factors Influencing Enveloping Slewing Drive SE9 Price

The premium performance of the SE9 is reflected in its price, influenced by several key factors:

High-Grade Materials and Complex Manufacturing: The significant quantity of high-strength alloy steel required for the large slewing ring and gears, coupled with the complex machining, precision grinding (especially critical for the enveloping profile), and specialized heat treatment processes, form a substantial portion of the cost. Manufacturing the large, robust housing is also complex.

Precision Grinding and Quality Assurance: Achieving the required micron-level tolerances through precision grinding of hardened gears is a time-consuming and costly process. Rigorous quality control throughout manufacturing, including extensive testing of load capacity and precision, adds significant value and cost.

Integrated Heavy-Duty Design Value: The price reflects the significant engineering and manufacturing value of integrating a large-capacity slewing bearing, a high-torque enveloping gearbox, and a sealed structural housing into one cohesive, ready-to-install unit. This integration provides immense value by simplifying the end-user's design and assembly process.

Advanced Sealing for IP65: Achieving and maintaining IP65 protection on a large, rotating assembly under heavy loads requires high-quality, durable seals, precise machining of sealing surfaces, and robust sealing strategies, contributing to the overall cost.

Scale and Complexity: Larger size inherently requires more material and more complex manufacturing processes compared to smaller drives like the SE7.

Customization: While a standard series, modifications such as special flange configurations, custom shaft outputs, unique lubrication ports or grease types, enhanced corrosion protection (e.g., coatings), specific electrical connections for feedback devices, or higher IP ratings will increase the unit price.

Order Volume and Supply Chain: Economies of scale apply to large orders. Global fluctuations in raw material costs (steel), energy, logistics, and currency exchange rates also impact final pricing.

Supplier Expertise and Support: The value provided by the supplier's engineering expertise, application support, comprehensive global warranty, and reliable delivery capabilities is factored into the pricing structure.

Supplier of Enveloping Slewing Drive SE9

LYRADRIVE is a leading global designer and manufacturer of high-performance slewing drives, renowned for its expertise in producing robust solutions like the advanced Enveloping Slewing Drive SE9 series. With a strong commitment to engineering excellence and rigorous quality control, LYRADRIVE leverages deep knowledge of gear technology and heavy-duty bearing design to deliver drives that excel in the most demanding applications worldwide. They specialize in integrated, reliable drive solutions backed by comprehensive technical support. For engineers seeking the unparalleled torque capacity, precision, self-locking security, and environmental resilience of the Enveloping Slewing Drive SE9 for heavy industrial, marine, or energy applications, LYRADRIVE stands as a trusted partner dedicated to performance and durability.