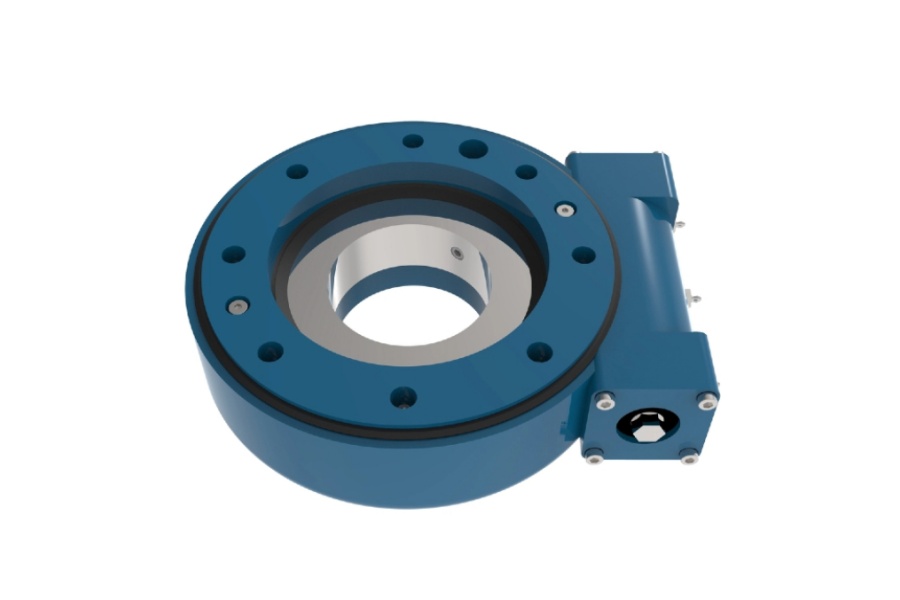

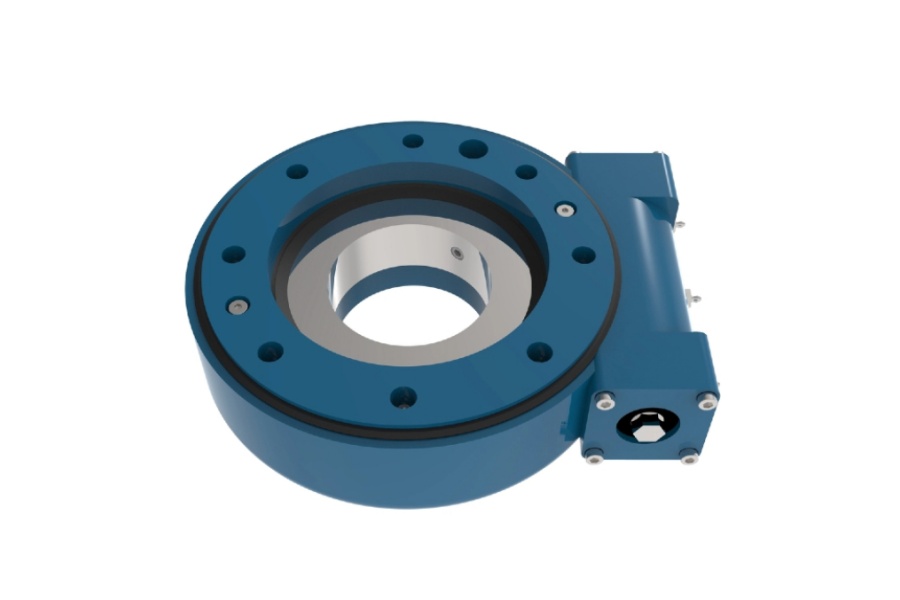

Enveloping Slewing Drive SE7 Power and Precision in a Robust Package

What is Enveloping Slewing Drive SE7

Enveloping Slewing Drive SE7 represents an advanced generation of integrated slewing ring bearings incorporating a precision worm gear drive mechanism within a single, robust housing. This design seamlessly combines the functions of a high-capacity bearing and a powerful, self-locking gear reduction unit. At its core, the SE7 features a hardened steel worm screw driving an enveloping-style worm wheel. The unique "enveloping" design of the worm wheel allows for significantly more tooth contact compared to standard worm gears – typically 4 to 5 teeth engage simultaneously with the worm screw. This multi-tooth engagement is the key to the SE7's outstanding torque transmission capabilities, exceptional load-bearing capacity (handling axial, radial, and moment loads concurrently), inherent smoothness, and its reliable self-locking characteristic. The entire assembly is encased within a protective housing, offering superior sealing and environmental protection. This integrated approach simplifies installation, enhances structural integrity, and provides a compact, high-performance solution for heavy-duty rotational motion.

Enveloping Slewing Drive SE7 Technical Information

The Enveloping Slewing Drive SE7 is defined by its robust engineering and precise specifications, tailored for high-stress environments:

Output Torque: 1500 N.m (The driving force available at the output)

Tilting Moment Torque: 13500 N.m (Resistance to overturning forces)

Holding Torque: 10400 N.m (Static holding capacity when not driven, enhanced by self-lock)

Static Axial Load Rating: 133 kN (Maximum stationary thrust load along the axis)

Static Radial Load Rating: 53 kN (Maximum stationary load perpendicular to the axis)

Dynamic Axial Load Rating: 32 kN (Maximum thrust load during rotation)

Dynamic Radial Load Rating: 28 kN (Maximum perpendicular load during rotation)

Gear Ratio: 73:1 (High reduction ratio for increased torque output and precise control)

Tracking Precision: ≤ 0.2° (High positional accuracy and repeatability; specific models achieve ≤0.07° or ≤0.1°)

Weight: 25 kg (Relatively compact and manageable weight for its power class)

Protection Rating: IP65 (Excellent sealing against dust ingress and low-pressure water jets, suitable for harsh environments)

Worm Wheel Design: Enveloping style, enabling multi-tooth contact (4-5 teeth simultaneously) for superior load distribution and torque capacity.

Self-Locking: Integral to the worm gear design, preventing back-driving when power is off, crucial for safety and position holding.

Enveloping Slewing Drive SE7 Features

The SE7's design translates into a compelling set of features that distinguish it in the market:

Exceptional Multi-Directional Load Capacity: Engineered to handle substantial combined loads – axial thrust, radial forces, and tilting moments – simultaneously, providing robust structural support and motion control within a single unit. This eliminates the need for complex external bearing arrangements.

High Torque Density: The enveloping worm gear mechanism, engaging multiple teeth, generates very high output torque (1500 N.m) and holding torque (10400 N.m) relative to its compact size and weight (25kg).

Superior Self-Locking Capability: The inherent efficiency of the worm gear design ensures reliable self-locking when drive power is removed. This is a critical safety feature for applications where maintaining position is paramount, preventing unintended movement due to external loads or gravity.

Enhanced Precision and Smoothness: Multi-tooth engagement contributes to smoother operation with reduced vibration and backlash compared to single-point contact gears. The high gear ratio (73:1) and precise manufacturing enable accurate positioning (≤0.2° tracking precision, with tighter options available).

Robust Sealing and Environmental Protection: The IP65-rated housing provides excellent defense against dust, dirt, and water, making the SE7 highly suitable for demanding outdoor applications and harsh industrial environments where contamination is a concern. This offers significant improvement over less protected standard S-series drives.

Integrated Design: Combining bearing, gearbox, and mounting structure into one pre-assembled, sealed unit drastically simplifies system design, reduces installation complexity, saves space, and enhances overall mechanical integrity and reliability. Sealing integrity is maintained at the factory.

High Durability and Long Service Life: The use of hardened steel components, optimized load distribution through multi-tooth contact, and effective sealing contribute to extended operational life and reduced maintenance requirements, even under continuous heavy-duty use.

Enveloping Slewing Drive SE7 Applications

The powerful combination of features makes the Enveloping Slewing Drive SE7 ideal for a wide range of demanding applications across diverse industries:

Solar Tracking Systems: Crucial for precise positioning of large photovoltaic panels and concentrated solar power (CSP) heliostats/mirrors. Its high torque, precision, self-locking capability (essential for wind stability), IP65 rating, and ability to handle combined wind loads are perfectly suited for this critical renewable energy application.

Construction and Material Handling Equipment: Found in crane jibs, man-lift platforms, compact crane turntables, and robotic arms where robust load handling, precise positioning, and safety (self-lock) are non-negotiable.

Heavy-Duty Industrial Automation: Used in welding positioners, heavy-duty indexing tables, pallet changers, and large robotic base rotations requiring high torque, rigidity, and precise angular control under load.

Medical and Scientific Equipment: Applied in advanced imaging systems (CT, MRI gantries - where precision and smoothness are vital), radiotherapy equipment positioning, and large laboratory apparatus requiring stable and accurate rotational movement.

Defense and Aerospace: Employed in radar antenna pedestals, weapon system mounts, satellite communication dishes, and ground support equipment demanding reliability, precision, and high load capacity in potentially harsh conditions.

Agricultural Machinery: Used in large sprayer booms and specialized harvesting equipment requiring robust, sealed drives for reliable operation in dusty and wet field conditions.

Packaging and Processing Machinery: Integrated into heavy rotary indexing machines, filling carousels, and large turntables where high throughput and precise positioning under load are essential.

Factors Influencing Enveloping Slewing Drive SE7 Price

The price of an Enveloping Slewing Drive SE7 unit is influenced by several key factors:

Material Costs and Manufacturing Complexity: The use of high-grade hardened steel for the worm and worm wheel, precision machining required for the enveloping gear profile, and specialized heat treatment processes significantly impact the base cost. The complexity of casting or machining the robust housing also contributes.

Precision Engineering and Quality Control: Achieving tight tolerances (especially for tracking precision ≤0.2° or better), ensuring smooth multi-tooth engagement, and rigorous quality control throughout manufacturing add considerable value and cost.

Integrated Design Value: The cost reflects the significant engineering value of integrating a high-capacity bearing, a precision gear reducer, and a sealed housing into a single, ready-to-install unit. This eliminates the cost and complexity of sourcing and assembling separate components.

Sealing and Protection Level: Achieving the IP65 rating requires high-quality seals, precise housing fits, and specific sealing strategies, adding to the component and assembly costs compared to less protected drives.

Customization: While the SE7 is a standard series, modifications such as special mounting flanges, custom shaft configurations, unique lubrication requirements, specific sealing upgrades, or special surface treatments (like coatings for extreme environments) will increase the price.

Order Volume and Supply Chain: Economies of scale apply; larger orders typically benefit from lower per-unit costs. Global material availability, logistics, and currency exchange rates also influence final pricing.

Supplier Value-Added Services: Technical support, application engineering assistance, comprehensive warranty coverage, reliable lead times, and global distribution networks contribute to the overall value proposition and can influence pricing structures.

Supplier of Enveloping Slewing Drive SE7

LYRADRIVE stands as a premier designer and manufacturer of high-performance slewing drives, including the advanced Enveloping Slewing Drive SE7 series. Renowned for engineering excellence and rigorous quality control, LYRADRIVE leverages deep expertise in gear technology and bearing design to produce drives that meet the most demanding application requirements globally. They focus on delivering robust, reliable, and innovative solutions, offering comprehensive technical support alongside their products. For industries requiring the superior torque capacity, precision, self-locking security, and environmental resilience of the Enveloping Slewing Drive SE7, LYRADRIVE represents a trusted source committed to performance and durability. Their dedication to integrated drive solutions positions them as a key partner for engineers tackling complex rotational motion challenges.