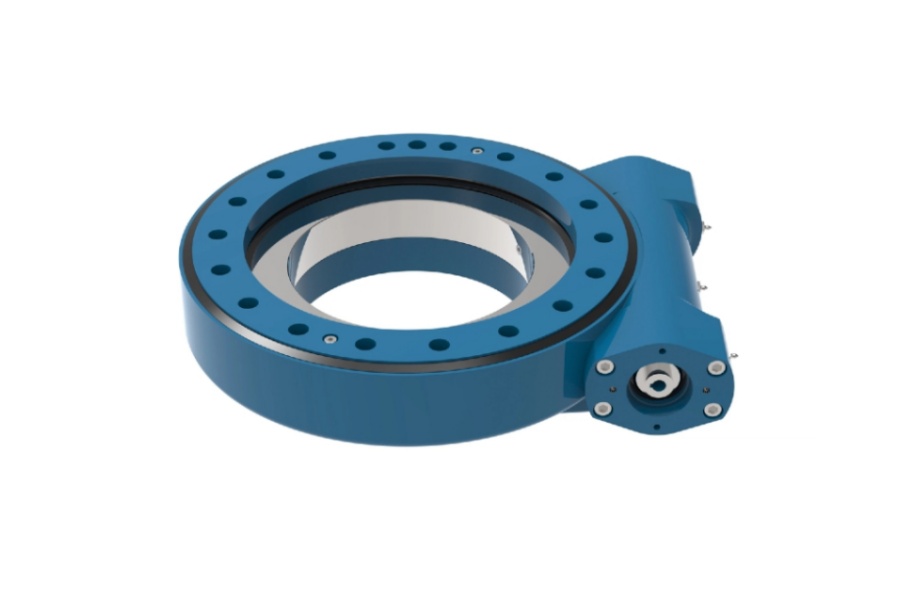

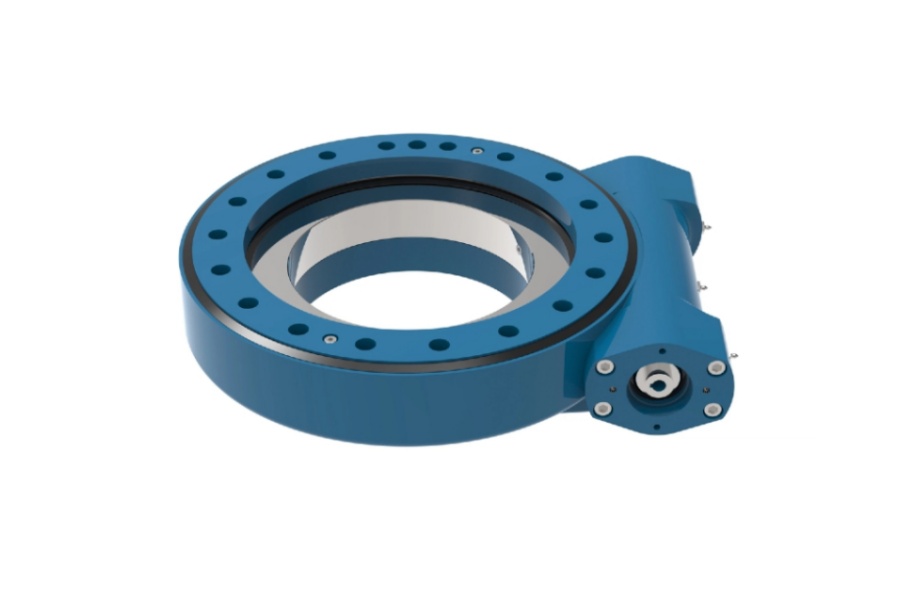

Enveloping Slewing Drive SE12 Technical Specifications and Applications

What is the Enveloping Slewing Drive SE12?

The Enveloping Slewing Drive SE12 is a self-contained, high-performance drive unit integrating critical components – a robust base housing, a precision-ground worm gear, and a hardened enveloping worm wheel – into a single, compact assembly. This integrated design eliminates complex alignment procedures typical of traditional systems, ensuring optimal gear meshing and force distribution from the outset. The "enveloping" geometry refers to the worm wheel's design, which partially wraps around the worm gear. This significantly increases the tooth contact area compared to standard worm gears, resulting in dramatically higher load capacity (axial, radial, and tilting moments), smoother operation, reduced wear, and superior durability under extreme conditions. The SE12 is not merely a gearbox; it's a complete, pre-engineered motion solution built for longevity and unwavering performance in harsh environments where failure is unacceptable.

Unmatched Rigidity for Complex Load Handling

The Enveloping Slewing Drive SE12 stands out due to its exceptional structural rigidity. This capability is fundamental to its ability to manage complex, multi-directional loads simultaneously:

Axial Loads: Forces acting parallel to the rotation axis.

Radial Loads: Forces acting perpendicular to the rotation axis.

Tilting Moments: Forces attempting to tip the rotating platform off-axis (a critical capability quantified by its 54.3 kN·m rated tilting moment capacity).

This multi-load capacity is essential for real-world applications where forces rarely act in a single, pure direction. The SE12 achieves this through a massively rigid, often monolithic or heavily reinforced housing acting as the foundational structure, precision-ground gear teeth ensuring maximum contact and optimal load distribution, and strategically placed high-quality bearings designed to absorb and transfer these complex forces efficiently. The resulting minimal deflection under load preserves critical alignment and ensures the positional accuracy of the driven equipment, even under severe operational stress. Its holding torque of 43 kN·m further underscores its ability to maintain position against significant external forces.

Precision Rotation for Particle Accelerator Vacuum Chambers

The stringent demands of particle accelerator technology make the Enveloping Slewing Drive SE12 an ideal solution for rotating components within ultra-high vacuum (UHV) chambers. These applications require:

Exceptional Precision: Maintaining critical alignment of beamline components is paramount. The SE12's inherent rigidity and precision gearing ensure minimal deflection and high positional accuracy.

Reliability & Zero Maintenance: Downtime in particle accelerators is extremely costly. The SE12's fully sealed design prevents lubricant leakage into the sensitive UHV environment and protects internal components from contamination. This design, combined with high-quality materials and manufacturing, ensures long-term, maintenance-free operation.

Compact, Integrated Design: Space within accelerator complexes is often highly constrained. The SE12's integrated, self-contained nature provides a high torque density solution without requiring complex external mounting structures.

High Torque & Load Capacity: Maneuvering heavy chamber components or experimental setups within the vacuum requires substantial torque and the ability to handle combined loads. The SE12's 7.5 kN·m output torque and robust load ratings meet this need.

Smooth, Controlled Motion: Precise, vibration-free rotation is essential to prevent disturbances to the particle beam or sensitive instrumentation. The enveloping gear design contributes to exceptionally smooth operation.

Key Features of the Enveloping Slewing Drive SE12

The SE12 incorporates several advanced features that define its performance envelope:

Integrated Enveloping Worm Gear Design: Maximizes contact area for high load capacity, smooth operation, and extended service life.

Exceptional Multi-Directional Load Capacity: Specifically rated to handle significant Axial Loads, Radial Loads, and Tilting Moments (54.3 kN·m) simultaneously.

High Torque Output & Holding Capacity: Delivers 7.5 kN·m output torque and provides a substantial 43 kN·m holding torque for secure positioning.

Fully Sealed & Protected Housing: Prevents ingress of contaminants and egress of lubricant, enabling reliable operation in dirty, wet, or UHV environments. Ensures long-term performance with minimal maintenance.

High Precision & Repeatability: Precision manufacturing ensures low backlash and high positioning accuracy (≤0.17° absolute, ≤0.05°/0.08° repeatability) critical for automated processes and sensitive instrumentation.

Self-Locking Capability: The inherent friction angle of the worm gear design provides a natural braking effect, enhancing safety by preventing back-driving under load when the drive is not powered (subject to specific load/ratio conditions).

Compact & Robust Construction: High torque density in a space-saving, rigid package simplifies integration and reduces the need for extensive support structures.

Optimized Gear Ratio: The 78:1 ratio provides an excellent balance between speed reduction, torque multiplication, and smooth motion control.

Diverse Industrial Applications of Enveloping Slewing Drive SE12

The combination of power, precision, rigidity, and reliability makes the Enveloping Slewing Drive SE12 suitable for a wide array of demanding applications:

Heavy-Duty Industrial Automation: Rotary indexing tables, heavy-duty positioners, welding turntables, material handling manipulators.

Robotics: Base rotation for large articulated robots or collaborative robot platforms requiring high payload and precision.

Renewable Energy: Solar tracker azimuth drives (especially in harsh environments or large, high-wind installations).

Material Handling & Logistics: Rotating platforms for sorting systems, palletizers, and heavy conveyor diverters.

Construction & Mining Equipment: Slewing mechanisms for compact cranes, drilling equipment, and inspection platforms.

Test & Simulation Equipment: High-fidelity motion simulators, structural test rigs requiring precise multi-axis loading.

Aerospace & Defense: Turret drives, antenna positioning systems, missile launch platform rotation.

Scientific & Research Equipment: Precision rotation within particle accelerator vacuum chambers, telescope mounts, and other sensitive instrumentation requiring UHV compatibility and high accuracy.

Factors Influencing Enveloping Slewing Drive SE12 Pricing

The cost of an Enveloping Slewing Drive SE12 unit is influenced by several key factors:

Material Specifications: The grade of steel used for the housing, worm, and worm wheel significantly impacts cost. Higher grades offer superior strength, wear resistance, and longevity but come at a premium. Special materials for corrosion resistance or UHV compatibility also increase price.

Precision Manufacturing & Quality Control: Achieving the tight tolerances required for high load capacity, smooth operation, and precise positioning demands advanced machining processes (like precision grinding) and rigorous quality control throughout manufacturing, adding to the cost.

Bearing Quality & Type: High-capacity, precision bearings capable of handling the rated axial, radial, and tilting moments are a major cost component. Sealed or specialty bearings add further expense.

Sealing & Protection Level: The complexity and quality of the sealing system (lip seals, labyrinth seals, special coatings) required for the intended environment (standard industrial, food-grade, submersible, UHV) directly affect the price.

Surface Treatments & Coatings: Specialized coatings (e.g., DLC - Diamond-Like Carbon on gear teeth) or surface hardening treatments (nitriding, carburizing) enhance wear resistance and longevity but add manufacturing steps and cost.

Customization: While the SE12 is a standard series, modifications such as custom mounting flanges, shaft configurations, special lubrication for extreme temperatures, or integrated sensors (encoders, temperature sensors) will increase the unit price.

Order Quantity: Bulk purchases typically benefit from economies of scale, reducing the unit cost compared to single-unit orders.

Supplier Value-Added Services: Engineering support for integration, extensive testing protocols, comprehensive warranties, and reliable after-sales service contribute to the overall value proposition and can be reflected in pricing.

Supplier of the Enveloping Slewing Drive SE12

LYRADRIVE is a recognized manufacturer specializing in the design and production of high-performance rotary drive solutions, including the Enveloping Slewing Drive SE12 series. They focus on engineering robust, precise, and reliable integrated drive systems capable of handling complex multi-directional loads for demanding industrial applications.