Engineering Machinery Slewing Bearing Selection Guide

What is Light Load Slewing Bearing

Light Load Slewing Bearing is a class of slewing rings engineered for applications with moderate combined loads (axial, radial, and tilting moments) relative to their size. Characterized by streamlined cross-sections, material efficiency, and often simplified sealing or gearing, these bearings deliver reliable rotation for machinery where extreme forces are absent but precision, durability, and cost-effectiveness are paramount.

Engineering Machinery Slewing Bearing Selection

Selecting the right slewing bearing involves a systematic evaluation of technical parameters and operational demands. Key factors include:

Load Analysis: Precisely quantify all operational loads:

Axial Load (F<sub>a</sub>): Vertical forces (e.g., component weight).

Radial Load (F<sub>r</sub>): Horizontal forces perpendicular to the axis (e.g., side loads during slewing).

Tilting Moment (M): Overturning forces (e.g., from cantilevered booms or off-center loads).

Calculate static and dynamic load cases. Light load bearings suit applications where these values fall within moderate ranges.

Bearing Type & Series Selection (Critical):

Match bearing structure to load profile:

Single-Row Four-Point Contact Ball (01 Series): Ideal for light to moderate combined loads. Compact, cost-effective, handles F<sub>a</sub>, M, and moderate F<sub>r</sub> simultaneously via ball/raceway contact geometry. Prime candidate for light load applications.

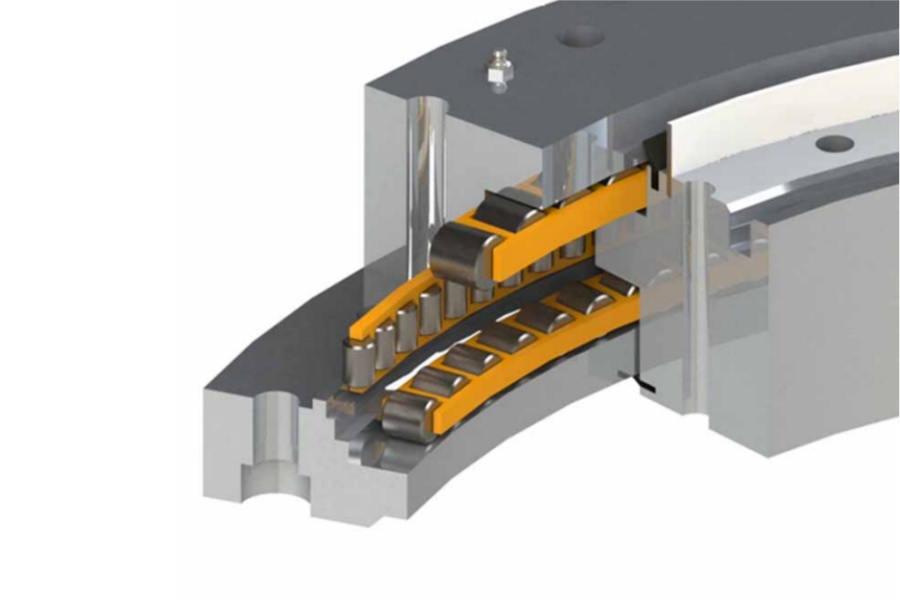

Double-Row Ball (02 Series): Suits higher M and F<sub>a</sub>. Two ball rows share loads; often designed with different ball sizes (larger upper row handles higher moment). Not typically "light load" unless machine size is small.

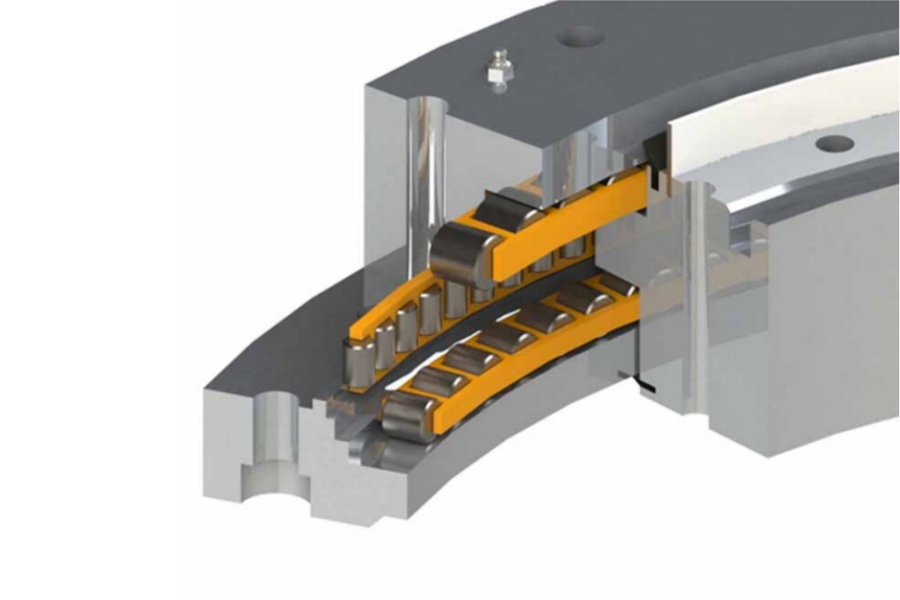

Single-Row Crossed Roller (11 Series): Excels in high-precision, high-rigidity light to medium load applications. Cylindrical/tapered rollers at 90° handle F<sub>a</sub>, F<sub>r</sub>, and M efficiently with minimal deformation. Excellent choice where precision trumps ultimate capacity.

Three-Row Roller (13 Series): Designed for very high F<sub>r</sub> and F<sub>a</sub> (e.g., large excavators, cranes). Separate rows handle radial and axial loads. Generally not suitable for light load applications.

Gearing Requirements:

Does the application need integrated gear teeth (internal/external) for direct drive? Light load bearings often omit gearing to reduce cost unless essential. Specify module, tooth count, and quality class if required.

Speed & Motion Profile:

Consider average and peak rotational speeds, duty cycle (continuous/intermittent), and acceleration/deceleration. Standard light load bearings suffice for slow, controlled slewing common in engineering machinery.

Environmental Conditions:

Assess exposure to dust, dirt, water, chemicals, temperature extremes, or corrosive agents. This dictates sealing requirements (e.g., single lip vs. multi-lip seals, seal material like NBR or FKM) and potential need for corrosion-resistant materials or coatings.

Mounting & Space Constraints:

Define available space envelope (diameter, height), bolt circle diameter (BCD), bolt size/quantity, and mounting surface requirements (flatness, machining). Light load bearings offer compact profiles.

Life Expectancy & Maintenance:

Target L10 life based on application criticality. Light load bearings, when correctly sized and maintained, offer long service life. Consider accessibility for greasing and inspection.

Light Load Slewing Bearing Characteristics

Optimized for efficiency in moderate-duty scenarios:

Compact & Lightweight: Reduced cross-section and material use compared to heavy-duty counterparts.

Cost-Effective: Lower initial investment achieved through optimized design and manufacturing.

Moderate Load Capacity: Engineered for defined F<sub>a</sub>, F<sub>r</sub>, and M thresholds typical of smaller or less intensely loaded machinery.

Simplified Sealing: Often features single or double lip seals sufficient for standard industrial environments.

Material Efficiency: Utilizes high-quality carbon steels or cost-effective alloys with targeted hardening (e.g., induction hardening).

Gearing Optional: Internal/external gears available if needed, but often excluded for pure rotation functions to save cost.

Smooth Operation: Precision raceways ensure low friction and vibration.

Light Load Slewing Bearing Applications

Ideal for numerous engineering machinery sectors:

Compact Construction Equipment: Mini-excavators, small telehandlers, compact loaders (boom rotation, accessory turntables).

Material Handling: Light-duty rotators, positioning tables, conveyor diverters, pallet turners.

Agricultural Machinery: Grain auger bases, sprayer boom pivots, fertilizer spreader turntables.

Mobile Cranes (Smaller): Boom foot bearings or auxiliary hook rotators on lower capacity models.

Aerial Work Platforms: Rotation mechanisms for light booms and baskets.

Industrial Automation: Welding positioners, assembly turntables, indexing stations.

Renewable Energy: Tracking drives for small-to-medium solar installations.

Forestry Equipment: Harvester head rotators on smaller units.

Factors Influencing Light Load Slewing Bearing Price

Cost is driven by design specifications and production variables:

Size & Basic Capacity: Diameter and nominal load ratings directly influence material volume.

Bearing Type: Crossed roller (11 Series) typically costs more than single-row ball (01 Series) for equivalent size.

Material Selection: Standard carbon steel (e.g., 50Mn, 42CrMo) is most economical; alloy steels or stainless variants increase cost.

Heat Treatment: Essential hardening processes (case hardening, induction hardening) contribute significantly. Complexity and depth requirements affect price.

Manufacturing Precision: Tolerances on raceways (roundness, profile), mounting surfaces, and bolt holes dictate machining effort. Tighter tolerances = higher cost.

Sealing: Basic single-lip seals are low-cost; multi-lip seals or specialized elastomers (FKM, HNBR) for harsh conditions add expense.

Integrated Gearing: Adding gear teeth (module size, helical vs. spur, hardening, quality class AGMA/DIN) substantially increases price.

Mounting Features: Complexity of bolt hole patterns, counterbores, pilot diameters, or tapped holes adds machining steps.

Quantity: Significant per-unit cost reduction with volume orders due to setup cost amortization.

Quality Control Level: Basic dimensional checks are standard; advanced Non-Destructive Testing (MPI, UT) or functional load testing adds cost.

Customization: Standard catalog bearings are cheapest; deviations in size, special seal configurations, unique materials, or non-standard features incur engineering and setup premiums.

Brand & Origin: Established premium brands command higher prices. Manufacturing location impacts labor and logistics costs.

Light Load Slewing Bearing Supplier LYRADRIVE

LYRADRIVE specializes in providing engineered light load slewing bearing solutions tailored for the specific demands of engineering machinery. They focus on delivering optimal performance, durability, and value through precision manufacturing, robust materials, and application expertise, supporting customers in selecting bearings that maximize reliability and lifecycle efficiency.