Efficient Load Handling and Precise Positioning: The Core Value of Slew Drives

What is a Slew Drive?

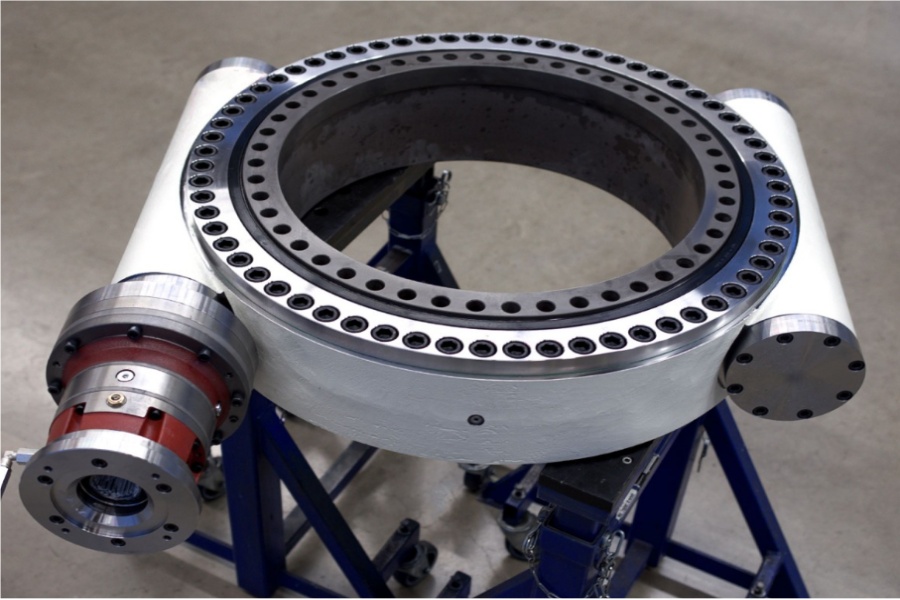

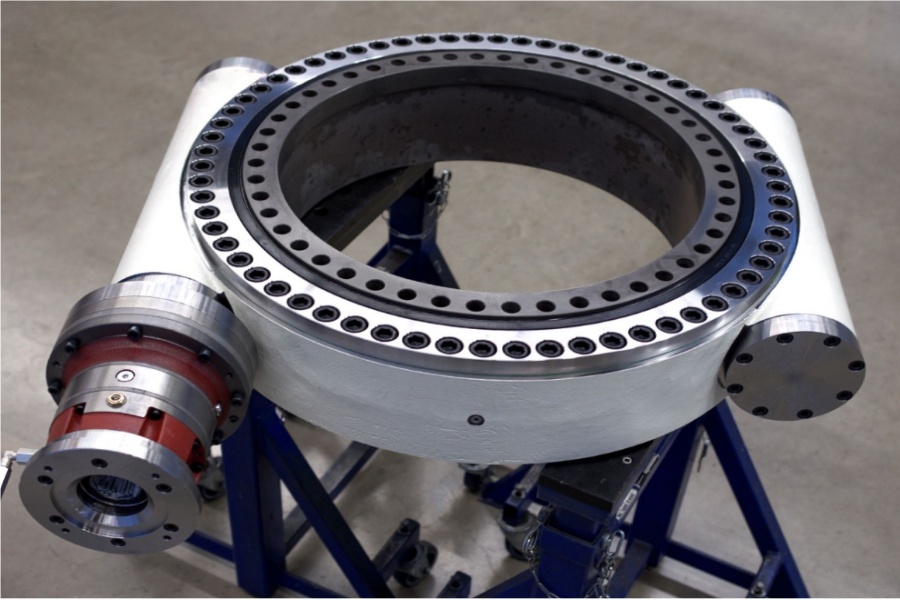

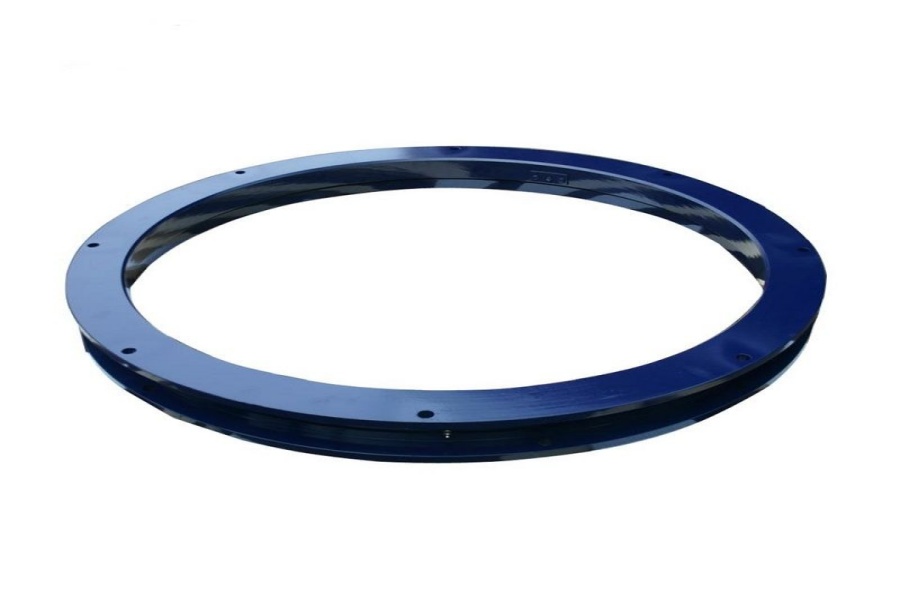

A slew drive is a highly integrated electromechanical device. Its core consists of a worm gear or planetary gear transmission system, a large slewing ring bearing, and a housing. It perfectly combines the functions of speed reduction, torque multiplication, power transmission, and withstanding enormous overturning moments, axial forces, and radial forces within a compact structure. A motor (typically a hydraulic motor or servo motor) drives the worm or pinion gear, which in turn rotates the large-diameter worm wheel or gear ring (integrated into the bearing), enabling 360-degree continuous or precise indexed rotation of the platform.

Core Characteristics of Slew Drives

Exceptional Load Capacity: Its core advantage lies in its ability to simultaneously withstand massive axial forces, radial forces, and overturning moments, making it ideal for heavy-duty equipment.

High-Precision Positioning: The worm gear structure inherently offers self-locking capability (at specific lead angles) and enables precise angular control, meeting high-accuracy rotational demands.

Compact Structure: The high integration of reduction gearing, power transmission, and support functions significantly saves space and reduces design complexity.

High Rigidity: Robust bearing and housing designs ensure system stability under heavy loads, minimizing deformation and vibration.

Smooth Operation: Precision gear meshing guarantees smooth, low-noise operation.

Easy Integration: Modular design simplifies installation and maintenance procedures.

Wide Range of Applications

The superior performance of slew drives makes them essential across numerous industries:

Construction Machinery: Cranes, excavators, rotary drilling rigs, concrete pump trucks (providing stable rotational support for booms).

Solar Power Generation: Solar trackers (precisely driving PV panels to follow the sun – a core component).

Wind Power Generation: Yaw and pitch systems (accurately adjusting blade angles and nacelle direction).

Industrial Automation: Large welding positioners, material handling turntables, radar pedestals, automated assembly line rotaries.

Medical & Military: CT scanner rotating gantries, radar systems, artillery, missile launchers, and other precision equipment.

Key Points for Slew Drive Selection Calculation

Selection requires careful consideration of critical parameters:

Load Analysis: Precisely calculate the axial force (Fa), radial force (Fr), and overturning moment (M) acting on the slew drive. This is the foundation of selection.

Duty Cycle: Evaluate whether the load operates continuously or intermittently, and the duty ratio.

Speed Requirement: Determine the required output speed.

Accuracy Requirement: Define rotational positioning accuracy, repeatability, and backlash requirements.

Environmental Factors: Operating temperature, humidity, dust, corrosive conditions, etc.

Drive Torque Calculation: Calculate the required input torque based on load torque, friction torque, and acceleration torque: T_input = (T_load + T_friction + T_acceleration) / (i * η) (where i is the gear ratio, η is the efficiency).

Typically, manufacturer-provided selection software or calculation services are used, inputting these parameters for precise matching.

Solar Trackers: A Key Application for Slew Drives

In the photovoltaic field, slew drives are the core driving component of single-axis (horizontal single-axis, tilted single-axis) and dual-axis solar trackers. Their advantages include:

Precise Sun Tracking: High-precision transmission ensures PV panels efficiently track the sun, significantly boosting power generation (by 15%-40%).

Wind Load Resistance: Robust construction withstands enormous overturning moments caused by severe weather (especially strong winds), protecting PV panels.

Reliability & Durability: Adapts to harsh outdoor environments with prolonged exposure to sun, rain, and temperature fluctuations, ensuring long-term stable operation.

Simplified Structure: Integrated solution simplifies tracker structure design, reducing installation and maintenance costs.

The Core of the Slew Drive: Gearbox Structure

Although often viewed as a single unit, its internal gearbox is crucial for power conversion:

Worm Gear Type: The most common form. A worm drives a worm wheel, offering high reduction ratios, compact size, self-locking capability (under specific conditions), and smooth operation. It's the preferred choice for solar trackers and similar applications.

Planetary Gear Type: Offers extremely high torque density and efficiency, suitable for applications requiring higher dynamic performance or continuous rotation (e.g., some construction machinery).

Crossed Roller Bearing Integration: Precision bearings directly integrated into the gearbox output end are key for efficiently handling overturning moments.

Key Factors Influencing Slew Drive Price

Price variations stem mainly from:

Size & Load Capacity: Larger sizes and higher load capacity requirements (torque, axial force, radial force) significantly increase material and manufacturing costs.

Gear Type & Precision: Precision worm gears (especially high-precision ground teeth) or planetary gears cost more than standard gears. Higher accuracy grades (e.g., smaller backlash) increase machining costs.

Materials & Manufacturing Processes: Using high-strength alloy steel for critical components (gears, bearing rings), special heat treatments (like carburizing, quenching, tooth hardening), and precision grinding substantially increase costs. Housing material (cast steel, aluminum alloy) and manufacturing processes also impact price.

Protection Rating (IP) & Sealing: Higher protection ratings (e.g., IP65 and above) and long-lasting sealing designs for harsh environments add material and manufacturing costs.

Brand & Customization Level: Well-known brands typically command a premium. Highly customized drives (special sizes, interfaces, materials, coatings) cost more than standard products. Bulk purchasing usually offers price advantages.

Additional Features & Accessories: Integrated encoders, brakes, special lubrication systems, or sensors add to the cost

Supplier of Slew drive

LYRA Drive is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.